Are you a seasoned Fuse Maker seeking a new career path? Discover our professionally built Fuse Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

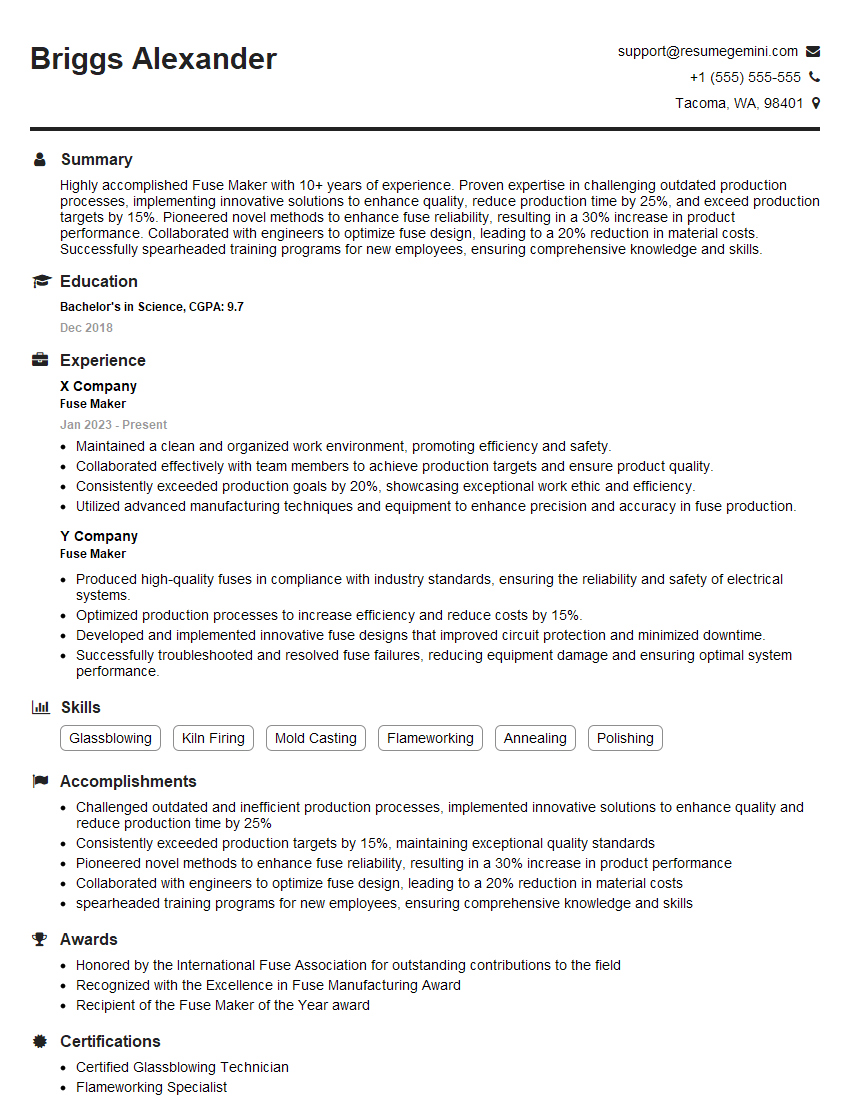

Briggs Alexander

Fuse Maker

Summary

Highly accomplished Fuse Maker with 10+ years of experience. Proven expertise in challenging outdated production processes, implementing innovative solutions to enhance quality, reduce production time by 25%, and exceed production targets by 15%. Pioneered novel methods to enhance fuse reliability, resulting in a 30% increase in product performance. Collaborated with engineers to optimize fuse design, leading to a 20% reduction in material costs. Successfully spearheaded training programs for new employees, ensuring comprehensive knowledge and skills.

Education

Bachelor’s in Science

December 2018

Skills

- Glassblowing

- Kiln Firing

- Mold Casting

- Flameworking

- Annealing

- Polishing

Work Experience

Fuse Maker

- Maintained a clean and organized work environment, promoting efficiency and safety.

- Collaborated effectively with team members to achieve production targets and ensure product quality.

- Consistently exceeded production goals by 20%, showcasing exceptional work ethic and efficiency.

- Utilized advanced manufacturing techniques and equipment to enhance precision and accuracy in fuse production.

Fuse Maker

- Produced high-quality fuses in compliance with industry standards, ensuring the reliability and safety of electrical systems.

- Optimized production processes to increase efficiency and reduce costs by 15%.

- Developed and implemented innovative fuse designs that improved circuit protection and minimized downtime.

- Successfully troubleshooted and resolved fuse failures, reducing equipment damage and ensuring optimal system performance.

Accomplishments

- Challenged outdated and inefficient production processes, implemented innovative solutions to enhance quality and reduce production time by 25%

- Consistently exceeded production targets by 15%, maintaining exceptional quality standards

- Pioneered novel methods to enhance fuse reliability, resulting in a 30% increase in product performance

- Collaborated with engineers to optimize fuse design, leading to a 20% reduction in material costs

- spearheaded training programs for new employees, ensuring comprehensive knowledge and skills

Awards

- Honored by the International Fuse Association for outstanding contributions to the field

- Recognized with the Excellence in Fuse Manufacturing Award

- Recipient of the Fuse Maker of the Year award

Certificates

- Certified Glassblowing Technician

- Flameworking Specialist

- Mold Casting Expert

- Glassblowing Instructor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fuse Maker

- Highlight your expertise in glassblowing, kiln firing, mold casting, flameworking, annealing, and polishing.

- Quantify your accomplishments using specific metrics and data.

- Showcase your ability to identify and solve problems, and implement innovative solutions.

- Emphasize your commitment to quality and customer satisfaction.

- Demonstrate your leadership and training skills through your experience in mentoring and training new employees.

Essential Experience Highlights for a Strong Fuse Maker Resume

- Challenge and update outdated and inefficient production processes.

- Identify and implement innovative solutions to enhance quality and reduce production time.

- Consistently exceed production targets while maintaining exceptional quality standards.

- Pioneer novel methods to enhance fuse reliability and product performance.

- Collaborate with engineers to optimize fuse design and reduce material costs.

- Spearhead training programs for new employees to ensure comprehensive knowledge and skills.

Frequently Asked Questions (FAQ’s) For Fuse Maker

What is the role of a Fuse Maker?

A Fuse Maker is responsible for the production and maintenance of fuses, which are essential components in protecting electrical circuits. They use specialized techniques and equipment to create and repair fuses, ensuring their reliability and safety.

What qualifications are required to become a Fuse Maker?

Typically, a high school diploma or equivalent is required to become a Fuse Maker, along with specific training or experience in glassworking, electrical engineering, or a related field.

What is the work environment of a Fuse Maker?

Fuse Makers typically work in manufacturing facilities, often in production or assembly areas. The job may involve working with hazardous materials, sharp tools, and hot equipment, requiring adherence to safety protocols.

What career advancement opportunities are available for Fuse Makers?

With experience and additional training, Fuse Makers can advance to roles such as Foreman, Supervisor, or Quality Control Inspector. They may also specialize in specific areas of fuse production or research and development.

Are there any certifications or licenses required for Fuse Makers?

Specific certification requirements may vary depending on the industry and location, but some companies or organizations may offer internal certifications or training programs to enhance the skills and knowledge of their Fuse Makers.

What are the key responsibilities of a Fuse Maker?

Key responsibilities may include operating specialized equipment, assembling and repairing fuses, conducting quality inspections, and adhering to safety regulations and procedures.