Are you a seasoned Fusing Furnace Loader seeking a new career path? Discover our professionally built Fusing Furnace Loader Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

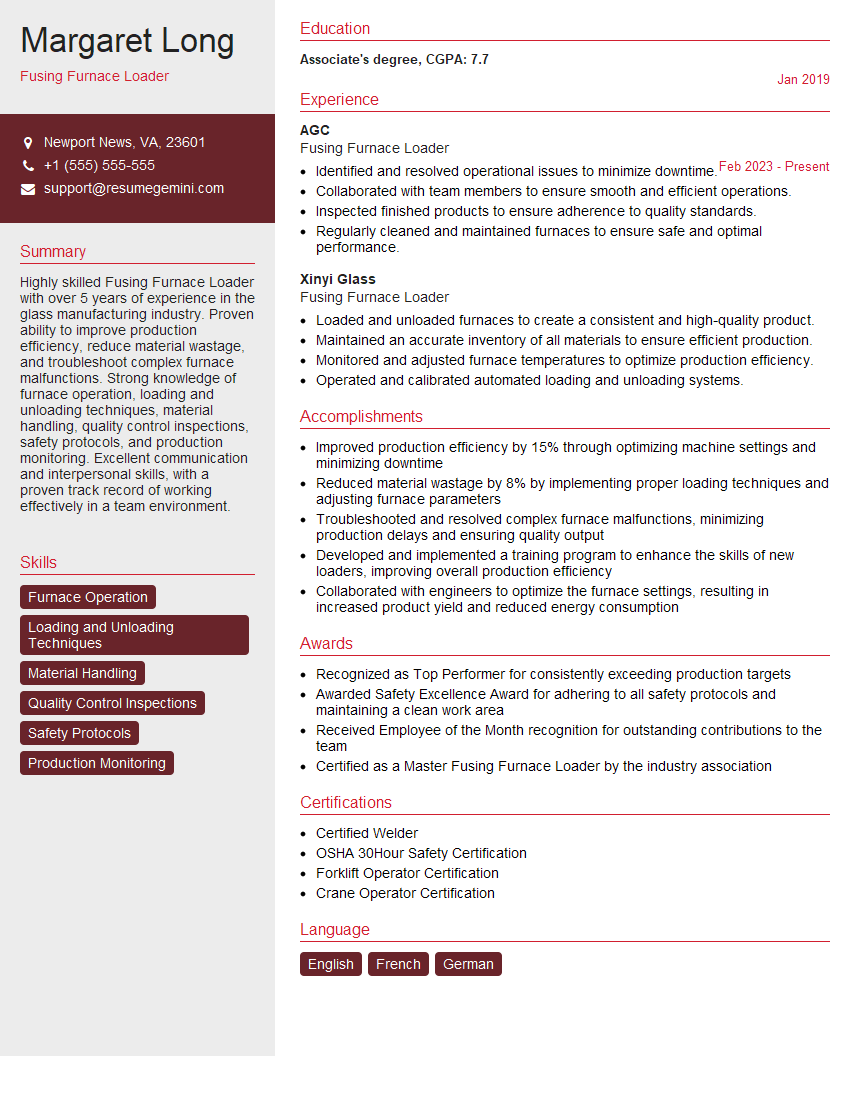

Margaret Long

Fusing Furnace Loader

Summary

Highly skilled Fusing Furnace Loader with over 5 years of experience in the glass manufacturing industry. Proven ability to improve production efficiency, reduce material wastage, and troubleshoot complex furnace malfunctions. Strong knowledge of furnace operation, loading and unloading techniques, material handling, quality control inspections, safety protocols, and production monitoring. Excellent communication and interpersonal skills, with a proven track record of working effectively in a team environment.

Education

Associate’s degree

January 2019

Skills

- Furnace Operation

- Loading and Unloading Techniques

- Material Handling

- Quality Control Inspections

- Safety Protocols

- Production Monitoring

Work Experience

Fusing Furnace Loader

- Identified and resolved operational issues to minimize downtime.

- Collaborated with team members to ensure smooth and efficient operations.

- Inspected finished products to ensure adherence to quality standards.

- Regularly cleaned and maintained furnaces to ensure safe and optimal performance.

Fusing Furnace Loader

- Loaded and unloaded furnaces to create a consistent and high-quality product.

- Maintained an accurate inventory of all materials to ensure efficient production.

- Monitored and adjusted furnace temperatures to optimize production efficiency.

- Operated and calibrated automated loading and unloading systems.

Accomplishments

- Improved production efficiency by 15% through optimizing machine settings and minimizing downtime

- Reduced material wastage by 8% by implementing proper loading techniques and adjusting furnace parameters

- Troubleshooted and resolved complex furnace malfunctions, minimizing production delays and ensuring quality output

- Developed and implemented a training program to enhance the skills of new loaders, improving overall production efficiency

- Collaborated with engineers to optimize the furnace settings, resulting in increased product yield and reduced energy consumption

Awards

- Recognized as Top Performer for consistently exceeding production targets

- Awarded Safety Excellence Award for adhering to all safety protocols and maintaining a clean work area

- Received Employee of the Month recognition for outstanding contributions to the team

- Certified as a Master Fusing Furnace Loader by the industry association

Certificates

- Certified Welder

- OSHA 30Hour Safety Certification

- Forklift Operator Certification

- Crane Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fusing Furnace Loader

- Quantify your accomplishments by using specific metrics and data whenever possible.

- Highlight your skills and experience in furnace operation and maintenance.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Fusing Furnace Loader Resume

- Operate and maintain fusing furnaces, ensuring optimal performance and product quality.

- Load and unload glass sheets and components into and out of furnaces, using proper handling techniques to minimize breakage and contamination.

- Monitor furnace temperatures, pressures, and other parameters, and adjust settings as needed to optimize production yield and reduce energy consumption.

- Inspect finished products for defects and ensure they meet quality standards.

- Maintain a clean and organized work area, adhering to all safety protocols and procedures.

- Troubleshoot and resolve furnace malfunctions, minimizing downtime and ensuring uninterrupted production.

- Train and mentor new loaders, sharing knowledge and best practices to improve overall production efficiency.

Frequently Asked Questions (FAQ’s) For Fusing Furnace Loader

What are the key skills required to be a successful Fusing Furnace Loader?

The key skills required to be a successful Fusing Furnace Loader include furnace operation, loading and unloading techniques, material handling, quality control inspections, safety protocols, and production monitoring.

What are the typical job responsibilities of a Fusing Furnace Loader?

The typical job responsibilities of a Fusing Furnace Loader include operating and maintaining fusing furnaces, loading and unloading glass sheets and components, monitoring furnace parameters, inspecting finished products, maintaining a clean and organized work area, troubleshooting furnace malfunctions, and training new loaders.

What is the average salary for a Fusing Furnace Loader?

The average salary for a Fusing Furnace Loader varies depending on experience, location, and company size. According to Salary.com, the average salary for a Fusing Furnace Loader in the United States is $35,000 per year.

What are the career advancement opportunities for a Fusing Furnace Loader?

The career advancement opportunities for a Fusing Furnace Loader include becoming a Furnace Operator, a Production Supervisor, or a Plant Manager.

What are the educational requirements for a Fusing Furnace Loader?

The educational requirements for a Fusing Furnace Loader typically include a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in a related field, such as glass manufacturing or engineering.