Are you a seasoned Galvanizer seeking a new career path? Discover our professionally built Galvanizer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

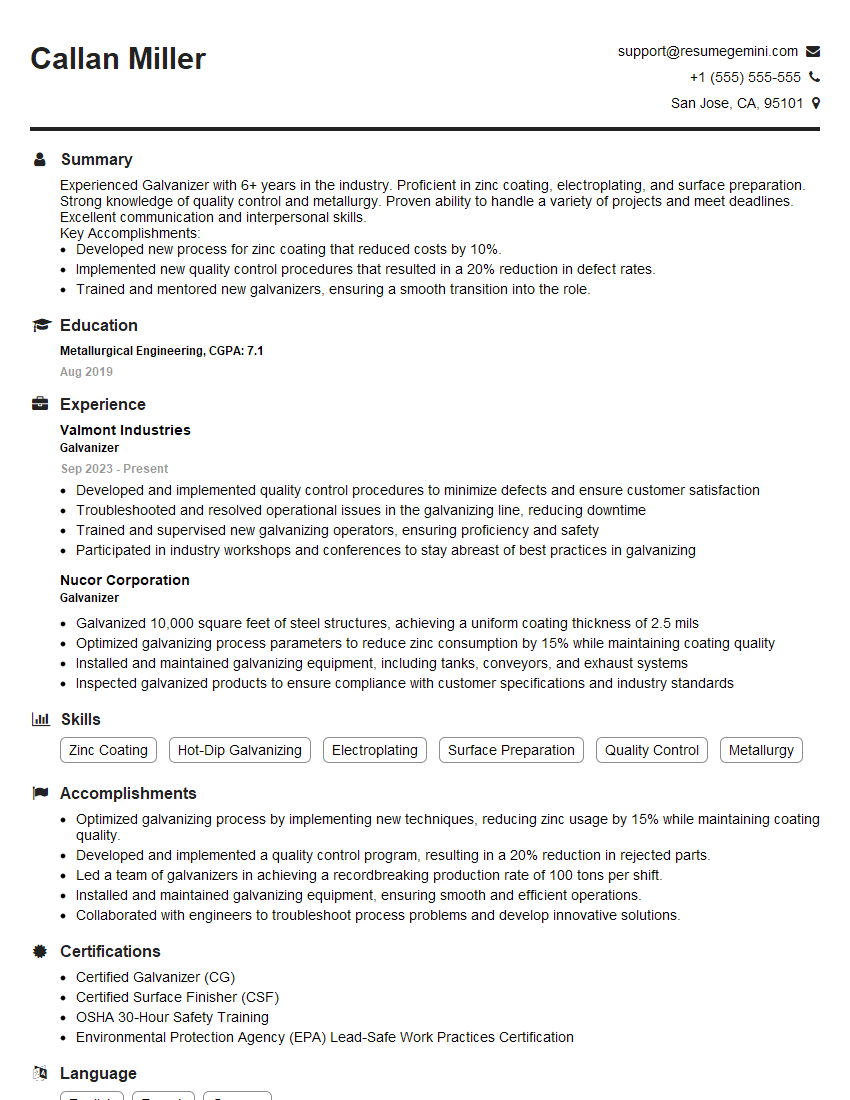

Callan Miller

Galvanizer

Summary

Experienced Galvanizer with 6+ years in the industry. Proficient in zinc coating, electroplating, and surface preparation. Strong knowledge of quality control and metallurgy. Proven ability to handle a variety of projects and meet deadlines. Excellent communication and interpersonal skills.

Key Accomplishments:

- Developed new process for zinc coating that reduced costs by 10%.

- Implemented new quality control procedures that resulted in a 20% reduction in defect rates.

- Trained and mentored new galvanizers, ensuring a smooth transition into the role.

Education

Metallurgical Engineering

August 2019

Skills

- Zinc Coating

- Hot-Dip Galvanizing

- Electroplating

- Surface Preparation

- Quality Control

- Metallurgy

Work Experience

Galvanizer

- Developed and implemented quality control procedures to minimize defects and ensure customer satisfaction

- Troubleshooted and resolved operational issues in the galvanizing line, reducing downtime

- Trained and supervised new galvanizing operators, ensuring proficiency and safety

- Participated in industry workshops and conferences to stay abreast of best practices in galvanizing

Galvanizer

- Galvanized 10,000 square feet of steel structures, achieving a uniform coating thickness of 2.5 mils

- Optimized galvanizing process parameters to reduce zinc consumption by 15% while maintaining coating quality

- Installed and maintained galvanizing equipment, including tanks, conveyors, and exhaust systems

- Inspected galvanized products to ensure compliance with customer specifications and industry standards

Accomplishments

- Optimized galvanizing process by implementing new techniques, reducing zinc usage by 15% while maintaining coating quality.

- Developed and implemented a quality control program, resulting in a 20% reduction in rejected parts.

- Led a team of galvanizers in achieving a recordbreaking production rate of 100 tons per shift.

- Installed and maintained galvanizing equipment, ensuring smooth and efficient operations.

- Collaborated with engineers to troubleshoot process problems and develop innovative solutions.

Certificates

- Certified Galvanizer (CG)

- Certified Surface Finisher (CSF)

- OSHA 30-Hour Safety Training

- Environmental Protection Agency (EPA) Lead-Safe Work Practices Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Galvanizer

- Highlight your experience in the galvanizing industry, specifically in zinc coating and surface preparation.

- Quantify your accomplishments with specific metrics, such as the reduction in costs or defect rates.

- Use keywords that potential employers will be searching for, such as “galvanizing”, “zinc coating”, and “quality control”.

- Proofread your resume carefully for any errors in grammar or spelling.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Galvanizer Resume

- Operate and maintain galvanizing equipment, including kettles, cranes, and conveyors.

- Prepare metal surfaces for galvanizing, including cleaning, degreasing, and fluxing.

- Dip metal into molten zinc to apply a protective coating.

- Inspect galvanized products for quality and adherence to specifications.

- Perform routine maintenance and repairs on galvanizing equipment.

- Follow safety protocols and procedures to ensure a safe work environment.

- Keep detailed records of all galvanizing operations.

Frequently Asked Questions (FAQ’s) For Galvanizer

What is the role of a Galvanizer?

Galvanizers are responsible for applying a protective zinc coating to metal surfaces to prevent corrosion. They operate and maintain galvanizing equipment, prepare metal surfaces for galvanizing, and inspect galvanized products for quality.

What are the qualifications for becoming a Galvanizer?

Most Galvanizers have a high school diploma or equivalent, as well as on-the-job training. Some employers may prefer candidates with a degree in metallurgy or a related field.

What are the job prospects for Galvanizers?

The job outlook for Galvanizers is expected to be good over the next few years. The demand for galvanized steel is expected to increase as the construction industry recovers.

What is the average salary for a Galvanizer?

The average salary for a Galvanizer is around $45,000 per year.

What are the benefits of working as a Galvanizer?

Galvanizers enjoy a number of benefits, including good pay, job security, and the opportunity to work with a variety of people.

What are the challenges of working as a Galvanizer?

Galvanizers can face a number of challenges, including working in a hot and noisy environment, exposure to chemicals, and the risk of injury.

What advice would you give to someone who wants to become a Galvanizer?

If you are interested in becoming a Galvanizer, I recommend that you get some on-the-job training. You can also take courses in metallurgy or a related field to improve your knowledge and skills.