Are you a seasoned Garland Machine Operator seeking a new career path? Discover our professionally built Garland Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

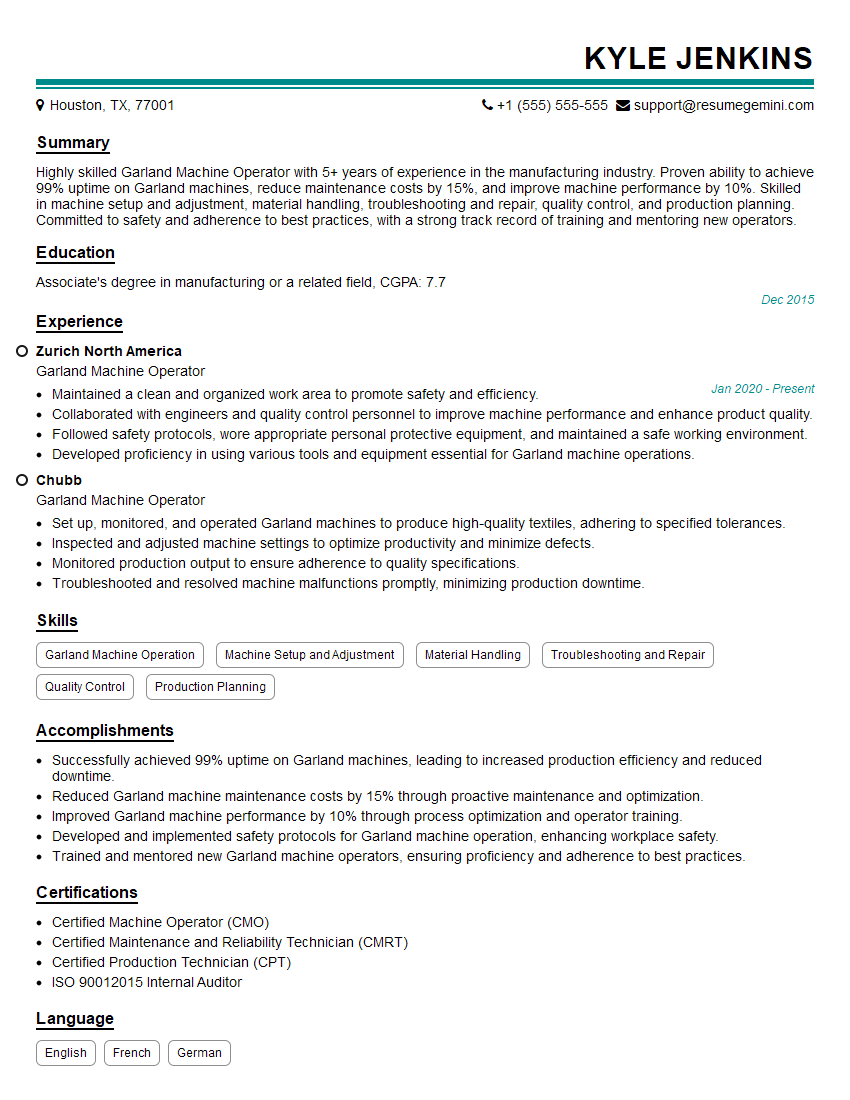

Kyle Jenkins

Garland Machine Operator

Summary

Highly skilled Garland Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to achieve 99% uptime on Garland machines, reduce maintenance costs by 15%, and improve machine performance by 10%. Skilled in machine setup and adjustment, material handling, troubleshooting and repair, quality control, and production planning. Committed to safety and adherence to best practices, with a strong track record of training and mentoring new operators.

Education

Associate’s degree in manufacturing or a related field

December 2015

Skills

- Garland Machine Operation

- Machine Setup and Adjustment

- Material Handling

- Troubleshooting and Repair

- Quality Control

- Production Planning

Work Experience

Garland Machine Operator

- Maintained a clean and organized work area to promote safety and efficiency.

- Collaborated with engineers and quality control personnel to improve machine performance and enhance product quality.

- Followed safety protocols, wore appropriate personal protective equipment, and maintained a safe working environment.

- Developed proficiency in using various tools and equipment essential for Garland machine operations.

Garland Machine Operator

- Set up, monitored, and operated Garland machines to produce high-quality textiles, adhering to specified tolerances.

- Inspected and adjusted machine settings to optimize productivity and minimize defects.

- Monitored production output to ensure adherence to quality specifications.

- Troubleshooted and resolved machine malfunctions promptly, minimizing production downtime.

Accomplishments

- Successfully achieved 99% uptime on Garland machines, leading to increased production efficiency and reduced downtime.

- Reduced Garland machine maintenance costs by 15% through proactive maintenance and optimization.

- Improved Garland machine performance by 10% through process optimization and operator training.

- Developed and implemented safety protocols for Garland machine operation, enhancing workplace safety.

- Trained and mentored new Garland machine operators, ensuring proficiency and adherence to best practices.

Certificates

- Certified Machine Operator (CMO)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Production Technician (CPT)

- ISO 90012015 Internal Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Garland Machine Operator

- Highlight your experience and skills in operating Garland machines, including specific metrics and accomplishments.

- Quantify your results whenever possible to demonstrate your impact on the organization.

- Showcase your knowledge of Garland machine maintenance and repair procedures.

- Emphasize your commitment to safety and adherence to best practices.

- Include keywords related to the Garland machine industry, such as “Garland machine operation,” “machine setup,” and “quality control.”

Essential Experience Highlights for a Strong Garland Machine Operator Resume

- Operate Garland machines to produce high-quality products within required specifications.

- Set up and adjust Garland machines according to production requirements and maintain optimal performance.

- Handle and manage materials efficiently to minimize waste and maximize productivity.

- Troubleshoot and repair Garland machines to ensure smooth operation and minimize downtime.

- Conduct quality control checks on finished products to ensure adherence to standards.

- Plan and schedule production activities to optimize efficiency and meet deadlines.

- Train and mentor new Garland machine operators to ensure proficiency and safety.

Frequently Asked Questions (FAQ’s) For Garland Machine Operator

What is a Garland machine?

A Garland machine is a type of automated sewing machine used in the manufacturing of garments, upholstery, and other sewn products. It is designed to perform specific sewing operations, such as seaming, topstitching, and embroidery.

What are the key skills required for a Garland Machine Operator?

Key skills for a Garland Machine Operator include the ability to operate and maintain Garland machines, handle and manage materials efficiently, troubleshoot and repair machines, conduct quality control checks, and follow safety protocols.

What are the career prospects for a Garland Machine Operator?

Garland Machine Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or Maintenance Technician. With additional training and experience, they may also become Garland Machine Trainers or Manufacturing Engineers.

What is the average salary for a Garland Machine Operator?

The average salary for a Garland Machine Operator in the United States is around $25,000 per year.

What are the working conditions for a Garland Machine Operator?

Garland Machine Operators typically work in a manufacturing environment, operating Garland machines in a production line setting. The work can be repetitive and physically demanding, requiring??? standing and operating machinery.

Is there a certification for Garland Machine Operators?

There is no specific certification for Garland Machine Operators. However, some manufacturers may offer training and certification programs for their own Garland machine models.

What are the safety precautions that Garland Machine Operators should follow?

Garland Machine Operators should follow all safety protocols established by their employer, including wearing appropriate safety gear, operating machines only when properly trained, and reporting any safety concerns or hazards.