Are you a seasoned Garnett Machine Operator seeking a new career path? Discover our professionally built Garnett Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

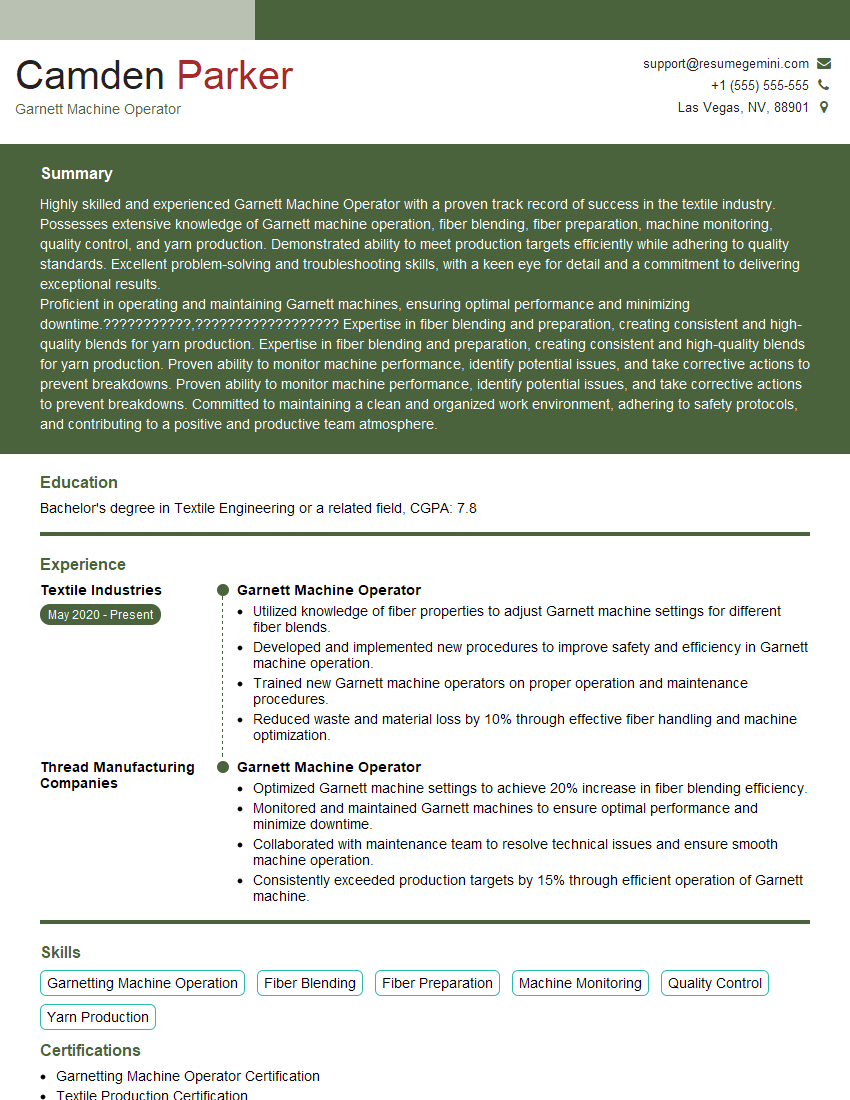

Camden Parker

Garnett Machine Operator

Summary

Highly skilled and experienced Garnett Machine Operator with a proven track record of success in the textile industry. Possesses extensive knowledge of Garnett machine operation, fiber blending, fiber preparation, machine monitoring, quality control, and yarn production. Demonstrated ability to meet production targets efficiently while adhering to quality standards. Excellent problem-solving and troubleshooting skills, with a keen eye for detail and a commitment to delivering exceptional results.

Proficient in operating and maintaining Garnett machines, ensuring optimal performance and minimizing downtime.???????????,?????????????????? Expertise in fiber blending and preparation, creating consistent and high-quality blends for yarn production. Expertise in fiber blending and preparation, creating consistent and high-quality blends for yarn production. Proven ability to monitor machine performance, identify potential issues, and take corrective actions to prevent breakdowns. Proven ability to monitor machine performance, identify potential issues, and take corrective actions to prevent breakdowns. Committed to maintaining a clean and organized work environment, adhering to safety protocols, and contributing to a positive and productive team atmosphere.

Education

Bachelor’s degree in Textile Engineering or a related field

April 2016

Skills

- Garnetting Machine Operation

- Fiber Blending

- Fiber Preparation

- Machine Monitoring

- Quality Control

- Yarn Production

Work Experience

Garnett Machine Operator

- Utilized knowledge of fiber properties to adjust Garnett machine settings for different fiber blends.

- Developed and implemented new procedures to improve safety and efficiency in Garnett machine operation.

- Trained new Garnett machine operators on proper operation and maintenance procedures.

- Reduced waste and material loss by 10% through effective fiber handling and machine optimization.

Garnett Machine Operator

- Optimized Garnett machine settings to achieve 20% increase in fiber blending efficiency.

- Monitored and maintained Garnett machines to ensure optimal performance and minimize downtime.

- Collaborated with maintenance team to resolve technical issues and ensure smooth machine operation.

- Consistently exceeded production targets by 15% through efficient operation of Garnett machine.

Certificates

- Garnetting Machine Operator Certification

- Textile Production Certification

- Lean Manufacturing Certification

- ISO 9001 Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Garnett Machine Operator

- Tailor your resume to each specific job you apply for, highlighting relevant skills and experience

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling

- Consider including a cover letter that showcases your enthusiasm for the position and explains why you are the ideal candidate

Essential Experience Highlights for a Strong Garnett Machine Operator Resume

- Operate Garnett machines to blend and prepare fibers for yarn production

- Monitor machine performance, identify potential issues, and take corrective actions

- Ensure consistent fiber quality and blend ratios to meet production specifications

- Troubleshoot and resolve machine malfunctions to minimize downtime

- Maintain a clean and organized work area, adhering to safety protocols

- Collaborate with other team members to ensure smooth production processes

- Stay updated on industry best practices and advancements in Garnett machine operation

Frequently Asked Questions (FAQ’s) For Garnett Machine Operator

What is the primary function of a Garnett machine?

A Garnett machine is primarily used for blending and preparing fibers for yarn production. It opens up and separates individual fibers, removes impurities, and aligns them in a parallel orientation, creating a uniform and consistent blend for spinning into yarn.

What are the key skills required for a Garnett Machine Operator?

Essential skills for a Garnett Machine Operator include proficiency in Garnett machine operation, fiber blending and preparation, machine monitoring, quality control, and yarn production. Additionally, they should possess problem-solving and troubleshooting abilities, a keen eye for detail, and a commitment to safety.

What is the work environment of a Garnett Machine Operator like?

Garnett Machine Operators typically work in manufacturing facilities, operating and maintaining Garnett machines. While the environment may be noisy and involve exposure to dust and fibers, employers prioritize safety and provide appropriate protective gear to ensure a safe working environment.

What are the career advancement opportunities for a Garnett Machine Operator?

With experience and additional training, Garnett Machine Operators can advance to roles such as Production Supervisor, Quality Control Manager, or even Plant Manager. They may also specialize in specific areas of textile manufacturing, such as nonwoven fabric production or yarn spinning.

How can I improve my chances of getting hired as a Garnett Machine Operator?

To increase your chances of getting hired, consider obtaining a degree in Textile Engineering or a related field, gaining practical experience through internships or apprenticeships, and developing strong technical skills in Garnett machine operation and fiber preparation.

What is the salary range for a Garnett Machine Operator?

The salary range for a Garnett Machine Operator can vary depending on factors such as experience, location, and company size. According to Indeed, the average salary for a Garnett Machine Operator in the United States is around $35,000 per year.

What is the job outlook for Garnett Machine Operators?

The job outlook for Garnett Machine Operators is expected to be stable in the coming years. As the textile industry continues to evolve, the demand for skilled operators who can operate and maintain Garnett machines efficiently remains strong.

Are there any specific certifications or training programs available for Garnett Machine Operators?

While not mandatory, there are industry-recognized certifications and training programs available for Garnett Machine Operators. These programs can provide specialized knowledge and enhance your skills, making you a more competitive candidate in the job market.