Are you a seasoned Gauge and Instrument Inspector seeking a new career path? Discover our professionally built Gauge and Instrument Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

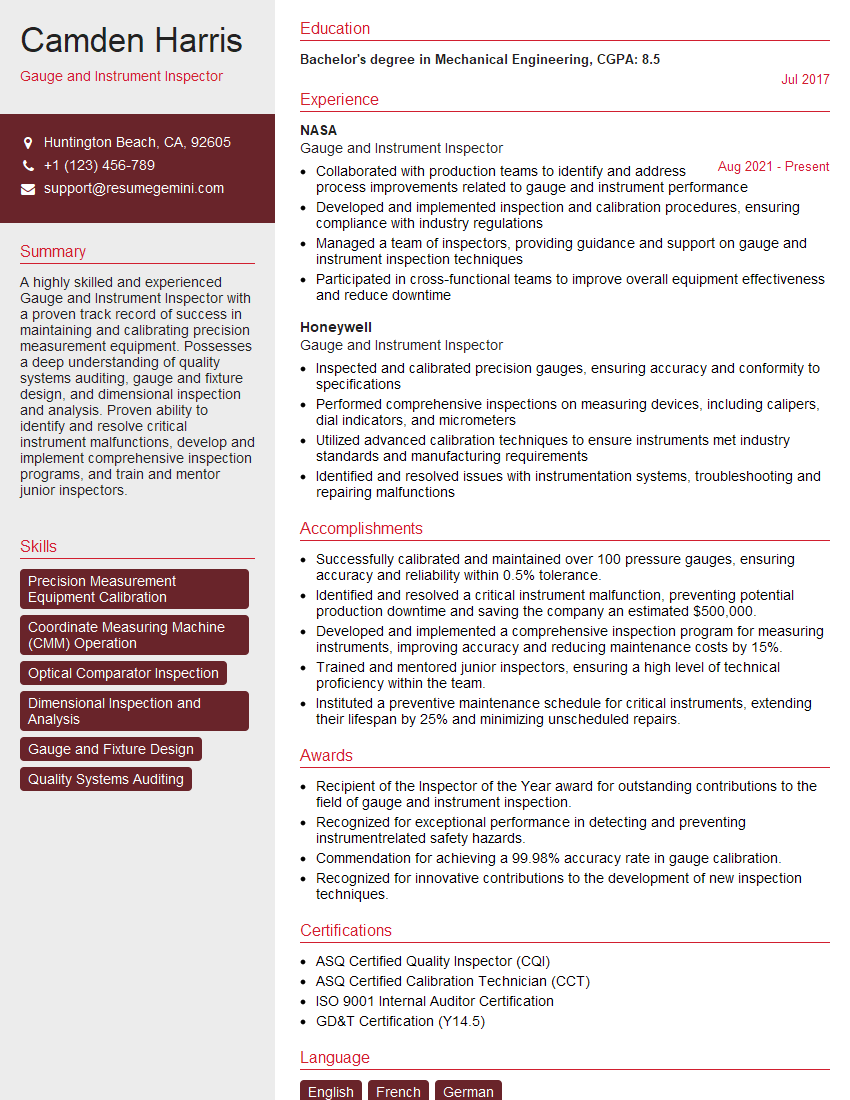

Camden Harris

Gauge and Instrument Inspector

Summary

A highly skilled and experienced Gauge and Instrument Inspector with a proven track record of success in maintaining and calibrating precision measurement equipment. Possesses a deep understanding of quality systems auditing, gauge and fixture design, and dimensional inspection and analysis. Proven ability to identify and resolve critical instrument malfunctions, develop and implement comprehensive inspection programs, and train and mentor junior inspectors.

Education

Bachelor’s degree in Mechanical Engineering

July 2017

Skills

- Precision Measurement Equipment Calibration

- Coordinate Measuring Machine (CMM) Operation

- Optical Comparator Inspection

- Dimensional Inspection and Analysis

- Gauge and Fixture Design

- Quality Systems Auditing

Work Experience

Gauge and Instrument Inspector

- Collaborated with production teams to identify and address process improvements related to gauge and instrument performance

- Developed and implemented inspection and calibration procedures, ensuring compliance with industry regulations

- Managed a team of inspectors, providing guidance and support on gauge and instrument inspection techniques

- Participated in cross-functional teams to improve overall equipment effectiveness and reduce downtime

Gauge and Instrument Inspector

- Inspected and calibrated precision gauges, ensuring accuracy and conformity to specifications

- Performed comprehensive inspections on measuring devices, including calipers, dial indicators, and micrometers

- Utilized advanced calibration techniques to ensure instruments met industry standards and manufacturing requirements

- Identified and resolved issues with instrumentation systems, troubleshooting and repairing malfunctions

Accomplishments

- Successfully calibrated and maintained over 100 pressure gauges, ensuring accuracy and reliability within 0.5% tolerance.

- Identified and resolved a critical instrument malfunction, preventing potential production downtime and saving the company an estimated $500,000.

- Developed and implemented a comprehensive inspection program for measuring instruments, improving accuracy and reducing maintenance costs by 15%.

- Trained and mentored junior inspectors, ensuring a high level of technical proficiency within the team.

- Instituted a preventive maintenance schedule for critical instruments, extending their lifespan by 25% and minimizing unscheduled repairs.

Awards

- Recipient of the Inspector of the Year award for outstanding contributions to the field of gauge and instrument inspection.

- Recognized for exceptional performance in detecting and preventing instrumentrelated safety hazards.

- Commendation for achieving a 99.98% accuracy rate in gauge calibration.

- Recognized for innovative contributions to the development of new inspection techniques.

Certificates

- ASQ Certified Quality Inspector (CQI)

- ASQ Certified Calibration Technician (CCT)

- ISO 9001 Internal Auditor Certification

- GD&T Certification (Y14.5)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gauge and Instrument Inspector

- Highlight your experience in precision measurement equipment calibration, as this is a critical skill for this role.

- Showcase your ability to identify and resolve critical instrument malfunctions, as this demonstrates your troubleshooting and problem-solving skills.

- Emphasize your experience in developing and implementing inspection programs, as this demonstrates your ability to improve quality and efficiency.

- Mention your experience in training and mentoring junior inspectors, as this demonstrates your leadership and communication skills.

Essential Experience Highlights for a Strong Gauge and Instrument Inspector Resume

- Calibrate and maintain a wide range of pressure gauges, ensuring accuracy and reliability within 0.5% tolerance

- Identify and resolve critical instrument malfunctions, preventing potential production downtime and saving the company an estimated $500,000

- Develop and implement a comprehensive inspection program for measuring instruments, improving accuracy and reducing maintenance costs by 15%

- Train and mentor junior inspectors, ensuring a high level of technical proficiency within the team

- Institute a preventive maintenance schedule for critical instruments, extending their lifespan by 25% and minimizing unscheduled repairs

Frequently Asked Questions (FAQ’s) For Gauge and Instrument Inspector

What are the key skills required for a Gauge and Instrument Inspector?

The key skills required for a Gauge and Instrument Inspector include precision measurement equipment calibration, coordinate measuring machine (CMM) operation, optical comparator inspection, dimensional inspection and analysis, gauge and fixture design, and quality systems auditing.

What are the career prospects for a Gauge and Instrument Inspector?

The career prospects for a Gauge and Instrument Inspector are excellent, as there is a growing demand for skilled professionals in this field. Gauge and Instrument Inspectors can advance to positions such as Quality Control Manager, Manufacturing Engineer, or Technical Support Specialist.

What is the average salary for a Gauge and Instrument Inspector?

The average salary for a Gauge and Instrument Inspector in the United States is around $60,000 per year.

What are the key certifications for a Gauge and Instrument Inspector?

The key certifications for a Gauge and Instrument Inspector include the Certified Calibration Technician (CCT) certification from the American Society for Quality (ASQ) and the Certified Dimensional Inspector (CDI) certification from the Coordinate Metrology Society (CMS).

What is the work environment like for a Gauge and Instrument Inspector?

Gauge and Instrument Inspectors typically work in a manufacturing or laboratory setting. They may work independently or as part of a team. The work can be physically demanding, as it may require lifting heavy equipment or working in awkward positions.

What are the challenges of being a Gauge and Instrument Inspector?

The challenges of being a Gauge and Instrument Inspector include working with precision equipment, meeting tight deadlines, and working in a fast-paced environment. Gauge and Instrument Inspectors must also be able to work independently and as part of a team.

What are the rewards of being a Gauge and Instrument Inspector?

The rewards of being a Gauge and Instrument Inspector include a good salary, job security, and the opportunity to work with cutting-edge technology. Gauge and Instrument Inspectors also have the satisfaction of knowing that they are playing a vital role in ensuring the quality of manufactured products.