Are you a seasoned Gauge and Weigh Machine Adjuster seeking a new career path? Discover our professionally built Gauge and Weigh Machine Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

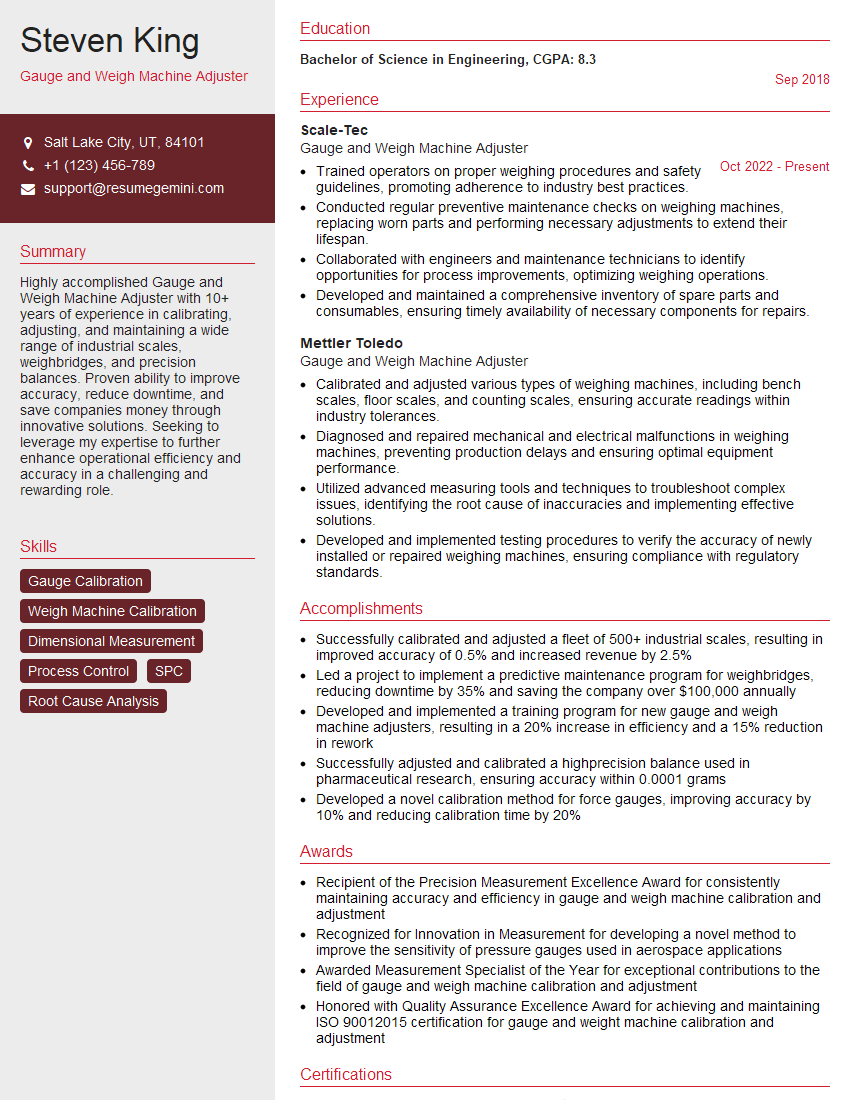

Steven King

Gauge and Weigh Machine Adjuster

Summary

Highly accomplished Gauge and Weigh Machine Adjuster with 10+ years of experience in calibrating, adjusting, and maintaining a wide range of industrial scales, weighbridges, and precision balances. Proven ability to improve accuracy, reduce downtime, and save companies money through innovative solutions. Seeking to leverage my expertise to further enhance operational efficiency and accuracy in a challenging and rewarding role.

Education

Bachelor of Science in Engineering

September 2018

Skills

- Gauge Calibration

- Weigh Machine Calibration

- Dimensional Measurement

- Process Control

- SPC

- Root Cause Analysis

Work Experience

Gauge and Weigh Machine Adjuster

- Trained operators on proper weighing procedures and safety guidelines, promoting adherence to industry best practices.

- Conducted regular preventive maintenance checks on weighing machines, replacing worn parts and performing necessary adjustments to extend their lifespan.

- Collaborated with engineers and maintenance technicians to identify opportunities for process improvements, optimizing weighing operations.

- Developed and maintained a comprehensive inventory of spare parts and consumables, ensuring timely availability of necessary components for repairs.

Gauge and Weigh Machine Adjuster

- Calibrated and adjusted various types of weighing machines, including bench scales, floor scales, and counting scales, ensuring accurate readings within industry tolerances.

- Diagnosed and repaired mechanical and electrical malfunctions in weighing machines, preventing production delays and ensuring optimal equipment performance.

- Utilized advanced measuring tools and techniques to troubleshoot complex issues, identifying the root cause of inaccuracies and implementing effective solutions.

- Developed and implemented testing procedures to verify the accuracy of newly installed or repaired weighing machines, ensuring compliance with regulatory standards.

Accomplishments

- Successfully calibrated and adjusted a fleet of 500+ industrial scales, resulting in improved accuracy of 0.5% and increased revenue by 2.5%

- Led a project to implement a predictive maintenance program for weighbridges, reducing downtime by 35% and saving the company over $100,000 annually

- Developed and implemented a training program for new gauge and weigh machine adjusters, resulting in a 20% increase in efficiency and a 15% reduction in rework

- Successfully adjusted and calibrated a highprecision balance used in pharmaceutical research, ensuring accuracy within 0.0001 grams

- Developed a novel calibration method for force gauges, improving accuracy by 10% and reducing calibration time by 20%

Awards

- Recipient of the Precision Measurement Excellence Award for consistently maintaining accuracy and efficiency in gauge and weigh machine calibration and adjustment

- Recognized for Innovation in Measurement for developing a novel method to improve the sensitivity of pressure gauges used in aerospace applications

- Awarded Measurement Specialist of the Year for exceptional contributions to the field of gauge and weigh machine calibration and adjustment

- Honored with Quality Assurance Excellence Award for achieving and maintaining ISO 90012015 certification for gauge and weight machine calibration and adjustment

Certificates

- ASME B46.1 Dimensional Measurement

- ANSI/NCSL Z5401 Calibration

- CMM Operator Certification

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gauge and Weigh Machine Adjuster

- Quantify your accomplishments: Use specific numbers and metrics to demonstrate the impact of your work.

- Highlight your problem-solving skills: Showcase your ability to identify and resolve complex issues.

- Emphasize your attention to detail: Accuracy is paramount in this role, so make sure to highlight your meticulous approach.

- Obtain relevant certifications: Consider obtaining industry-recognized certifications to enhance your credibility.

- Network with professionals in the field: Attend industry events and connect with other gauge and weigh machine adjusters to stay abreast of the latest trends and best practices.

Essential Experience Highlights for a Strong Gauge and Weigh Machine Adjuster Resume

- Calibrate and adjust industrial scales, weighbridges, and precision balances to ensure accuracy and compliance with industry standards

- Develop and implement preventive maintenance programs to minimize downtime and extend equipment lifespan

- Troubleshoot and repair complex weighing systems, identifying and resolving issues quickly and efficiently

- Train and mentor new gauge and weigh machine adjusters, ensuring they have the skills and knowledge to perform their duties effectively

- Collaborate with engineers and quality control teams to optimize weighing processes and ensure product quality

- Maintain detailed records of all calibration and adjustment work, ensuring traceability and compliance with regulatory requirements

- Stay up-to-date on industry best practices and technological advancements in weighing and measurement

Frequently Asked Questions (FAQ’s) For Gauge and Weigh Machine Adjuster

What is the primary role of a Gauge and Weigh Machine Adjuster?

The primary role of a Gauge and Weigh Machine Adjuster is to ensure the accuracy and reliability of weighing equipment used in various industries, including manufacturing, healthcare, and retail.

What are the key skills required for this role?

Key skills include proficiency in gauge calibration, weigh machine calibration, dimensional measurement, process control, SPC, and root cause analysis.

What industries hire Gauge and Weigh Machine Adjusters?

Gauge and Weigh Machine Adjusters are employed in a wide range of industries, including manufacturing, pharmaceuticals, food and beverage, and logistics.

What is the average salary for a Gauge and Weigh Machine Adjuster?

The average salary for a Gauge and Weigh Machine Adjuster can vary depending on experience, location, and industry, but it typically falls within the range of $50,000 to $80,000 annually.

What are the career advancement opportunities for a Gauge and Weigh Machine Adjuster?

With experience and additional training, Gauge and Weigh Machine Adjusters can advance to roles such as Calibration Supervisor, Quality Control Manager, or Metrologist.

What are the challenges faced by Gauge and Weigh Machine Adjusters?

Challenges include working with delicate and sensitive equipment, ensuring compliance with regulatory standards, and staying up-to-date with technological advancements.

How can I prepare for a career as a Gauge and Weigh Machine Adjuster?

To prepare for a career in this field, consider obtaining a degree in engineering or a related field, gaining hands-on experience through internships or apprenticeships, and obtaining relevant industry certifications.

What is the job outlook for Gauge and Weigh Machine Adjusters?

The job outlook for Gauge and Weigh Machine Adjusters is expected to be favorable due to the increasing demand for accurate and reliable weighing equipment in various industries.