Are you a seasoned Gauge and Weigh Machine Operator seeking a new career path? Discover our professionally built Gauge and Weigh Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

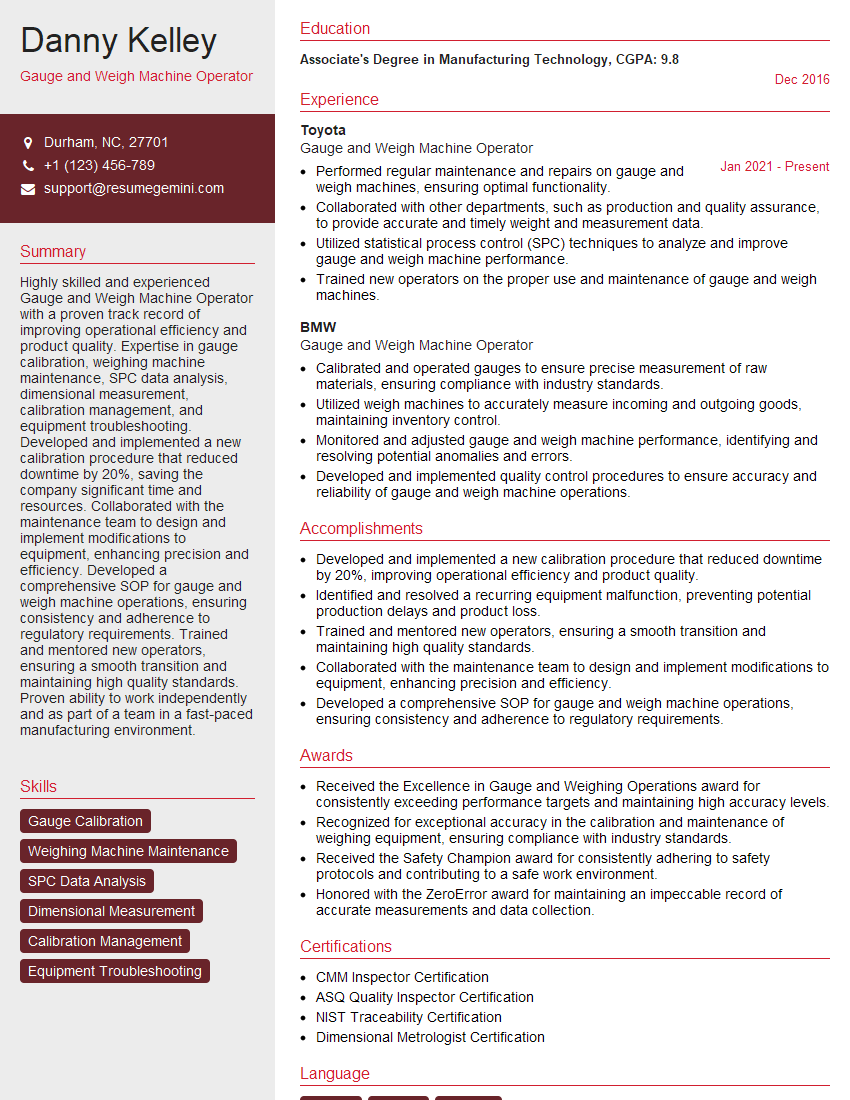

Danny Kelley

Gauge and Weigh Machine Operator

Summary

Highly skilled and experienced Gauge and Weigh Machine Operator with a proven track record of improving operational efficiency and product quality. Expertise in gauge calibration, weighing machine maintenance, SPC data analysis, dimensional measurement, calibration management, and equipment troubleshooting. Developed and implemented a new calibration procedure that reduced downtime by 20%, saving the company significant time and resources. Collaborated with the maintenance team to design and implement modifications to equipment, enhancing precision and efficiency. Developed a comprehensive SOP for gauge and weigh machine operations, ensuring consistency and adherence to regulatory requirements. Trained and mentored new operators, ensuring a smooth transition and maintaining high quality standards. Proven ability to work independently and as part of a team in a fast-paced manufacturing environment.

Education

Associate’s Degree in Manufacturing Technology

December 2016

Skills

- Gauge Calibration

- Weighing Machine Maintenance

- SPC Data Analysis

- Dimensional Measurement

- Calibration Management

- Equipment Troubleshooting

Work Experience

Gauge and Weigh Machine Operator

- Performed regular maintenance and repairs on gauge and weigh machines, ensuring optimal functionality.

- Collaborated with other departments, such as production and quality assurance, to provide accurate and timely weight and measurement data.

- Utilized statistical process control (SPC) techniques to analyze and improve gauge and weigh machine performance.

- Trained new operators on the proper use and maintenance of gauge and weigh machines.

Gauge and Weigh Machine Operator

- Calibrated and operated gauges to ensure precise measurement of raw materials, ensuring compliance with industry standards.

- Utilized weigh machines to accurately measure incoming and outgoing goods, maintaining inventory control.

- Monitored and adjusted gauge and weigh machine performance, identifying and resolving potential anomalies and errors.

- Developed and implemented quality control procedures to ensure accuracy and reliability of gauge and weigh machine operations.

Accomplishments

- Developed and implemented a new calibration procedure that reduced downtime by 20%, improving operational efficiency and product quality.

- Identified and resolved a recurring equipment malfunction, preventing potential production delays and product loss.

- Trained and mentored new operators, ensuring a smooth transition and maintaining high quality standards.

- Collaborated with the maintenance team to design and implement modifications to equipment, enhancing precision and efficiency.

- Developed a comprehensive SOP for gauge and weigh machine operations, ensuring consistency and adherence to regulatory requirements.

Awards

- Received the Excellence in Gauge and Weighing Operations award for consistently exceeding performance targets and maintaining high accuracy levels.

- Recognized for exceptional accuracy in the calibration and maintenance of weighing equipment, ensuring compliance with industry standards.

- Received the Safety Champion award for consistently adhering to safety protocols and contributing to a safe work environment.

- Honored with the ZeroError award for maintaining an impeccable record of accurate measurements and data collection.

Certificates

- CMM Inspector Certification

- ASQ Quality Inspector Certification

- NIST Traceability Certification

- Dimensional Metrologist Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gauge and Weigh Machine Operator

- Highlight your skills and experience in gauge calibration, weighing machine maintenance, and SPC data analysis.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the company.

- Showcase your ability to work independently and as part of a team in a fast-paced manufacturing environment.

- Emphasize your commitment to quality and continuous improvement.

- Tailor your resume to each job description, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Gauge and Weigh Machine Operator Resume

- Calibrating and maintaining gauge and weigh machines to ensure accuracy and precision.

- Performing dimensional measurements and SPC data analysis to ensure product quality.

- Troubleshooting and repairing equipment malfunctions to minimize downtime.

- Developing and implementing new procedures to improve operational efficiency.

- Training and mentoring new operators to maintain high quality standards.

- Collaborating with the maintenance team to design and implement equipment modifications.

- Ensuring compliance with regulatory requirements and industry best practices.

- Maintaining a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Gauge and Weigh Machine Operator

What are the primary responsibilities of a Gauge and Weigh Machine Operator?

Gauge and Weigh Machine Operators are responsible for calibrating, maintaining, and repairing gauges and weigh machines used in manufacturing and quality control. They also perform dimensional measurements and SPC data analysis to ensure product quality.

What skills are required to be a successful Gauge and Weigh Machine Operator?

Successful Gauge and Weigh Machine Operators have a strong understanding of gauge and weigh machine calibration, maintenance, and repair. They are also proficient in dimensional measurement and SPC data analysis. Additionally, they have strong troubleshooting skills and are able to work independently and as part of a team.

What is the work environment of a Gauge and Weigh Machine Operator like?

Gauge and Weigh Machine Operators typically work in manufacturing or quality control environments. They may work in a variety of settings, including factories, warehouses, and laboratories.

What are the career prospects for a Gauge and Weigh Machine Operator?

Gauge and Weigh Machine Operators can advance their careers by becoming supervisors or managers. They may also specialize in a particular area, such as gauge calibration or SPC data analysis.

What is the salary range for a Gauge and Weigh Machine Operator?

The salary range for a Gauge and Weigh Machine Operator varies depending on experience, skills, and location. According to Indeed, the average salary for a Gauge and Weigh Machine Operator in the United States is $25 per hour.

What are the educational requirements for a Gauge and Weigh Machine Operator?

Most Gauge and Weigh Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

How can I prepare for a career as a Gauge and Weigh Machine Operator?

To prepare for a career as a Gauge and Weigh Machine Operator, you can take courses in manufacturing technology, gauge calibration, and SPC data analysis. You can also gain experience by working in a manufacturing or quality control environment.

What are some of the challenges that Gauge and Weigh Machine Operators face?

Gauge and Weigh Machine Operators may face challenges such as working in a fast-paced environment, meeting production deadlines, and ensuring product quality.