Are you a seasoned Gauge Inspector seeking a new career path? Discover our professionally built Gauge Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

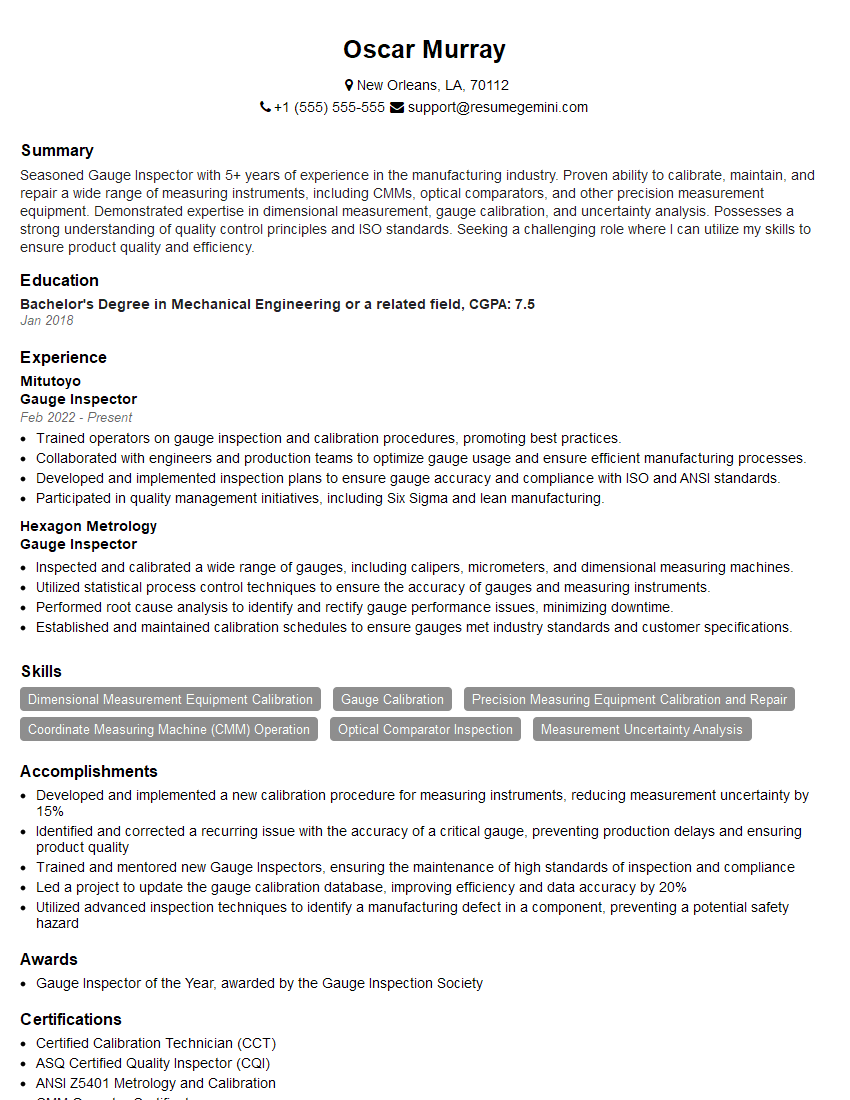

Oscar Murray

Gauge Inspector

Summary

Seasoned Gauge Inspector with 5+ years of experience in the manufacturing industry. Proven ability to calibrate, maintain, and repair a wide range of measuring instruments, including CMMs, optical comparators, and other precision measurement equipment. Demonstrated expertise in dimensional measurement, gauge calibration, and uncertainty analysis. Possesses a strong understanding of quality control principles and ISO standards. Seeking a challenging role where I can utilize my skills to ensure product quality and efficiency.

Education

Bachelor’s Degree in Mechanical Engineering or a related field

January 2018

Skills

- Dimensional Measurement Equipment Calibration

- Gauge Calibration

- Precision Measuring Equipment Calibration and Repair

- Coordinate Measuring Machine (CMM) Operation

- Optical Comparator Inspection

- Measurement Uncertainty Analysis

Work Experience

Gauge Inspector

- Trained operators on gauge inspection and calibration procedures, promoting best practices.

- Collaborated with engineers and production teams to optimize gauge usage and ensure efficient manufacturing processes.

- Developed and implemented inspection plans to ensure gauge accuracy and compliance with ISO and ANSI standards.

- Participated in quality management initiatives, including Six Sigma and lean manufacturing.

Gauge Inspector

- Inspected and calibrated a wide range of gauges, including calipers, micrometers, and dimensional measuring machines.

- Utilized statistical process control techniques to ensure the accuracy of gauges and measuring instruments.

- Performed root cause analysis to identify and rectify gauge performance issues, minimizing downtime.

- Established and maintained calibration schedules to ensure gauges met industry standards and customer specifications.

Accomplishments

- Developed and implemented a new calibration procedure for measuring instruments, reducing measurement uncertainty by 15%

- Identified and corrected a recurring issue with the accuracy of a critical gauge, preventing production delays and ensuring product quality

- Trained and mentored new Gauge Inspectors, ensuring the maintenance of high standards of inspection and compliance

- Led a project to update the gauge calibration database, improving efficiency and data accuracy by 20%

- Utilized advanced inspection techniques to identify a manufacturing defect in a component, preventing a potential safety hazard

Awards

- Gauge Inspector of the Year, awarded by the Gauge Inspection Society

Certificates

- Certified Calibration Technician (CCT)

- ASQ Certified Quality Inspector (CQI)

- ANSI Z5401 Metrology and Calibration

- CMM Operator Certificate

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gauge Inspector

- Quantify your accomplishments with specific metrics whenever possible. For example, instead of saying ‘Developed and implemented a new calibration procedure,’ you could say, ‘Developed and implemented a new calibration procedure, reducing measurement uncertainty by 15%.’

- Highlight your experience with specific software and equipment used in the industry, such as CMMs, optical comparators, and calibration software.

- Demonstrate your understanding of quality control principles and ISO standards, as they are essential for ensuring product quality and compliance.

- Showcase your ability to work independently and as part of a team, as Gauge Inspectors often collaborate with other quality control professionals and production staff.

- Consider obtaining certifications, such as the Certified Calibration Technician (CCT) certification from the American Society for Quality (ASQ), to demonstrate your expertise and commitment to the profession.

Essential Experience Highlights for a Strong Gauge Inspector Resume

- Calibrate and maintain a wide range of measuring instruments, including CMMs, optical comparators, and other precision measurement equipment.

- Develop and implement new calibration procedures to improve measurement accuracy and reduce uncertainty.

- Troubleshoot and resolve issues with measurement equipment, ensuring minimal downtime.

- Train and mentor new Gauge Inspectors, ensuring the maintenance of high standards of inspection and compliance.

- Supervise and manage a team of Gauge Inspectors, ensuring efficient and effective operations.

- Analyze measurement data to identify trends and patterns, and recommend improvements to processes and procedures.

- Manage the gauge calibration database, ensuring accuracy and accessibility of data.

Frequently Asked Questions (FAQ’s) For Gauge Inspector

What is the primary role of a Gauge Inspector?

Gauge Inspectors are responsible for ensuring the accuracy and reliability of measuring instruments used in manufacturing and quality control. They calibrate, maintain, and repair these instruments to ensure that they meet the required specifications and standards.

What skills are essential for a successful Gauge Inspector?

Essential skills for Gauge Inspectors include a strong understanding of dimensional measurement principles, calibration techniques, and quality control procedures. They should also be proficient in using various measuring instruments, including CMMs, optical comparators, and precision measuring equipment.

What are the career prospects for Gauge Inspectors?

Gauge Inspectors can advance their careers by becoming supervisors, quality control managers, or metrology engineers. They can also specialize in specific areas, such as dimensional metrology, calibration, or inspection.

What is the job outlook for Gauge Inspectors?

The job outlook for Gauge Inspectors is expected to grow in the coming years due to the increasing demand for quality control in various industries, including manufacturing, aerospace, and automotive.

What industries employ Gauge Inspectors?

Gauge Inspectors are employed in a wide range of industries, including manufacturing, aerospace, automotive, medical devices, and electronics.

What are the typical working conditions for Gauge Inspectors?

Gauge Inspectors typically work in a laboratory or quality control environment. They may be required to work with hazardous materials or operate heavy machinery, so safety precautions must be followed.

What is the salary range for Gauge Inspectors?

The salary range for Gauge Inspectors varies depending on experience, location, and industry. According to Glassdoor, the average salary for Gauge Inspectors in the United States is around $60,000 per year.