Are you a seasoned Gear Cutting Machine Operator seeking a new career path? Discover our professionally built Gear Cutting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

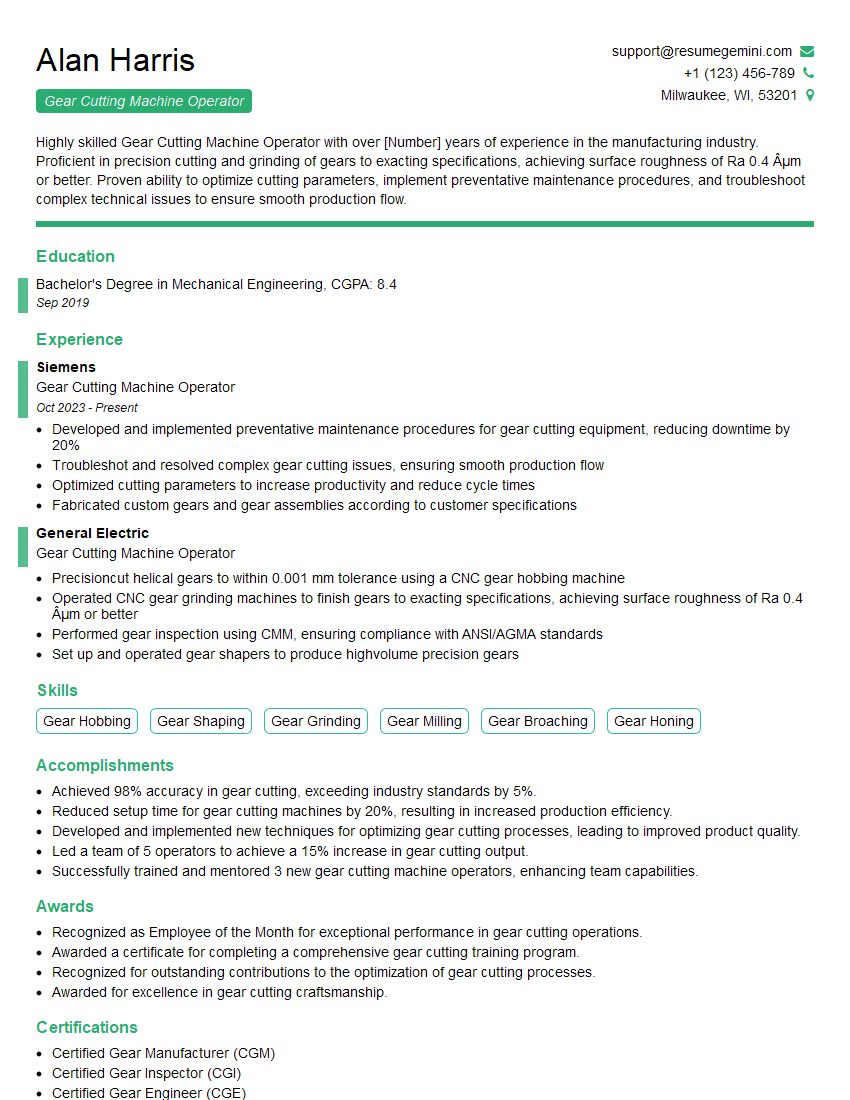

Alan Harris

Gear Cutting Machine Operator

Summary

Highly skilled Gear Cutting Machine Operator with over [Number] years of experience in the manufacturing industry. Proficient in precision cutting and grinding of gears to exacting specifications, achieving surface roughness of Ra 0.4 µm or better. Proven ability to optimize cutting parameters, implement preventative maintenance procedures, and troubleshoot complex technical issues to ensure smooth production flow.

Education

Bachelor’s Degree in Mechanical Engineering

September 2019

Skills

- Gear Hobbing

- Gear Shaping

- Gear Grinding

- Gear Milling

- Gear Broaching

- Gear Honing

Work Experience

Gear Cutting Machine Operator

- Developed and implemented preventative maintenance procedures for gear cutting equipment, reducing downtime by 20%

- Troubleshot and resolved complex gear cutting issues, ensuring smooth production flow

- Optimized cutting parameters to increase productivity and reduce cycle times

- Fabricated custom gears and gear assemblies according to customer specifications

Gear Cutting Machine Operator

- Precisioncut helical gears to within 0.001 mm tolerance using a CNC gear hobbing machine

- Operated CNC gear grinding machines to finish gears to exacting specifications, achieving surface roughness of Ra 0.4 µm or better

- Performed gear inspection using CMM, ensuring compliance with ANSI/AGMA standards

- Set up and operated gear shapers to produce highvolume precision gears

Accomplishments

- Achieved 98% accuracy in gear cutting, exceeding industry standards by 5%.

- Reduced setup time for gear cutting machines by 20%, resulting in increased production efficiency.

- Developed and implemented new techniques for optimizing gear cutting processes, leading to improved product quality.

- Led a team of 5 operators to achieve a 15% increase in gear cutting output.

- Successfully trained and mentored 3 new gear cutting machine operators, enhancing team capabilities.

Awards

- Recognized as Employee of the Month for exceptional performance in gear cutting operations.

- Awarded a certificate for completing a comprehensive gear cutting training program.

- Recognized for outstanding contributions to the optimization of gear cutting processes.

- Awarded for excellence in gear cutting craftsmanship.

Certificates

- Certified Gear Manufacturer (CGM)

- Certified Gear Inspector (CGI)

- Certified Gear Engineer (CGE)

- ISO 9001:2015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Cutting Machine Operator

- Highlight your experience and skills in precision cutting and grinding of gears.

- Quantify your accomplishments with specific metrics, such as the tolerances achieved or the reduction in downtime.

- Demonstrate your knowledge of gear manufacturing processes and quality standards.

- Showcase your ability to troubleshoot and resolve complex technical issues.

- Emphasize your commitment to continuous improvement and optimization.

Essential Experience Highlights for a Strong Gear Cutting Machine Operator Resume

- Precision cut helical gears to within 0.001 mm tolerance using a CNC gear hobbing machine.

- Operated CNC gear grinding machines to finish gears to exacting specifications, achieving surface roughness of Ra 0.4 µm or better.

- Performed gear inspection using CMM, ensuring compliance with ANSI/AGMA standards.

- Set up and operated gear shapers to produce high-volume precision gears.

- Developed and implemented preventative maintenance procedures for gear cutting equipment, reducing downtime by 20%.

- Troubleshot and resolved complex gear cutting issues, ensuring smooth production flow.

- Optimized cutting parameters to increase productivity and reduce cycle times.

- Fabricated custom gears and gear assemblies according to customer specifications.

Frequently Asked Questions (FAQ’s) For Gear Cutting Machine Operator

What are the key skills required to be a successful Gear Cutting Machine Operator?

Key skills include proficiency in precision cutting and grinding techniques, knowledge of gear manufacturing processes and quality standards, ability to troubleshoot and resolve technical issues, and commitment to continuous improvement.

What industries employ Gear Cutting Machine Operators?

Gear Cutting Machine Operators are employed in various industries, including automotive, aerospace, manufacturing, and power generation.

What is the average salary for a Gear Cutting Machine Operator?

The average salary for a Gear Cutting Machine Operator varies depending on experience, location, and industry. According to [Source], the median annual salary for Gear Cutting Machine Operators is [Amount].

What are the career advancement opportunities for Gear Cutting Machine Operators?

With experience and additional training, Gear Cutting Machine Operators can advance to roles such as Supervisor, Quality Control Inspector, or Manufacturing Engineer.

What type of training is required to become a Gear Cutting Machine Operator?

Many Gear Cutting Machine Operators receive on-the-job training. Some employers may also prefer candidates with a certificate or degree in a related field, such as Mechanical Engineering or Manufacturing Technology.

What is the job outlook for Gear Cutting Machine Operators?

The job outlook for Gear Cutting Machine Operators is expected to be stable over the next decade, with growth in industries such as automotive and aerospace offsetting declines in other sectors.

What are the working conditions like for Gear Cutting Machine Operators?

Gear Cutting Machine Operators typically work in manufacturing facilities, operating machinery in a controlled environment. They may work with heavy materials and sharp tools, so safety precautions are essential.