Are you a seasoned Gear Cutting Machine Set Up Operator seeking a new career path? Discover our professionally built Gear Cutting Machine Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

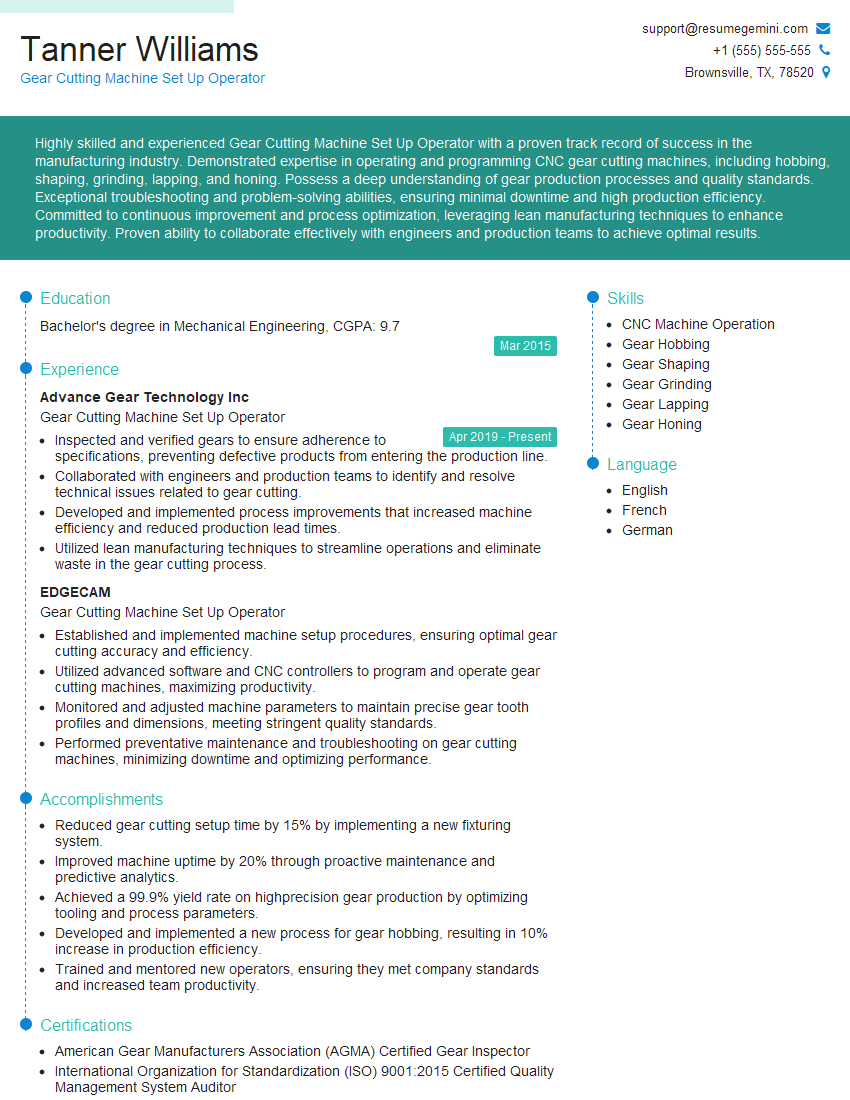

Tanner Williams

Gear Cutting Machine Set Up Operator

Summary

Highly skilled and experienced Gear Cutting Machine Set Up Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in operating and programming CNC gear cutting machines, including hobbing, shaping, grinding, lapping, and honing. Possess a deep understanding of gear production processes and quality standards. Exceptional troubleshooting and problem-solving abilities, ensuring minimal downtime and high production efficiency. Committed to continuous improvement and process optimization, leveraging lean manufacturing techniques to enhance productivity. Proven ability to collaborate effectively with engineers and production teams to achieve optimal results.

Education

Bachelor’s degree in Mechanical Engineering

March 2015

Skills

- CNC Machine Operation

- Gear Hobbing

- Gear Shaping

- Gear Grinding

- Gear Lapping

- Gear Honing

Work Experience

Gear Cutting Machine Set Up Operator

- Inspected and verified gears to ensure adherence to specifications, preventing defective products from entering the production line.

- Collaborated with engineers and production teams to identify and resolve technical issues related to gear cutting.

- Developed and implemented process improvements that increased machine efficiency and reduced production lead times.

- Utilized lean manufacturing techniques to streamline operations and eliminate waste in the gear cutting process.

Gear Cutting Machine Set Up Operator

- Established and implemented machine setup procedures, ensuring optimal gear cutting accuracy and efficiency.

- Utilized advanced software and CNC controllers to program and operate gear cutting machines, maximizing productivity.

- Monitored and adjusted machine parameters to maintain precise gear tooth profiles and dimensions, meeting stringent quality standards.

- Performed preventative maintenance and troubleshooting on gear cutting machines, minimizing downtime and optimizing performance.

Accomplishments

- Reduced gear cutting setup time by 15% by implementing a new fixturing system.

- Improved machine uptime by 20% through proactive maintenance and predictive analytics.

- Achieved a 99.9% yield rate on highprecision gear production by optimizing tooling and process parameters.

- Developed and implemented a new process for gear hobbing, resulting in 10% increase in production efficiency.

- Trained and mentored new operators, ensuring they met company standards and increased team productivity.

Certificates

- American Gear Manufacturers Association (AGMA) Certified Gear Inspector

- International Organization for Standardization (ISO) 9001:2015 Certified Quality Management System Auditor

- American Society for Quality (ASQ) Certified Quality Engineer

- American Society for Nondestructive Testing (ASNT) Certified Nondestructive Testing Technician

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Cutting Machine Set Up Operator

- Highlight your technical skills and experience in CNC gear cutting machine operation.

- Quantify your accomplishments with specific metrics to demonstrate your impact on productivity and quality.

- Showcase your problem-solving abilities and provide examples of how you have resolved complex issues.

- Emphasize your commitment to continuous improvement and process optimization.

- Tailor your resume and cover letter to the specific job requirements and company culture.

Essential Experience Highlights for a Strong Gear Cutting Machine Set Up Operator Resume

- Established and implemented machine setup procedures to ensure optimal gear cutting accuracy and efficiency.

- Programmed and operated CNC gear cutting machines utilizing advanced software and controllers, maximizing productivity.

- Monitored and adjusted machine parameters to maintain precise gear tooth profiles and dimensions, meeting stringent quality standards.

- Troubleshooted and performed preventative maintenance on gear cutting machines, minimizing downtime and optimizing performance.

- Inspected and verified gears to ensure adherence to specifications, preventing defective products from entering the production line.

- Collaborated with engineers and production teams to identify and resolve technical issues related to gear cutting.

- Developed and implemented process improvements that increased machine efficiency and reduced production lead times.

Frequently Asked Questions (FAQ’s) For Gear Cutting Machine Set Up Operator

What are the key skills required for a Gear Cutting Machine Set Up Operator?

CNC Machine Operation, Gear Hobbing, Gear Shaping, Gear Grinding, Gear Lapping, and Gear Honing are the key skills.

What is the role of a Gear Cutting Machine Set Up Operator?

A Gear Cutting Machine Set Up Operator is responsible for setting up and operating CNC gear cutting machines to produce gears with precise tooth profiles and dimensions.

What are the career prospects for a Gear Cutting Machine Set Up Operator?

With experience and additional training, Gear Cutting Machine Set Up Operators can advance to supervisory or management roles in the manufacturing industry.

What are the challenges faced by a Gear Cutting Machine Set Up Operator?

Challenges include working with complex machinery, adhering to tight tolerances, and meeting production deadlines.

What is the work environment like for a Gear Cutting Machine Set Up Operator?

Gear Cutting Machine Set Up Operators typically work in manufacturing facilities, operating machinery in a noisy environment.

What are the safety precautions that a Gear Cutting Machine Set Up Operator must follow?

Operators must wear appropriate safety gear, follow lockout/tagout procedures, and be aware of potential hazards.

What is the salary range for a Gear Cutting Machine Set Up Operator?

The salary range varies depending on experience, location, and company size.

What are the benefits of working as a Gear Cutting Machine Set Up Operator?

Benefits may include competitive pay, health insurance, paid time off, and opportunities for advancement.