Are you a seasoned Gear Generator Set Up Operator seeking a new career path? Discover our professionally built Gear Generator Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

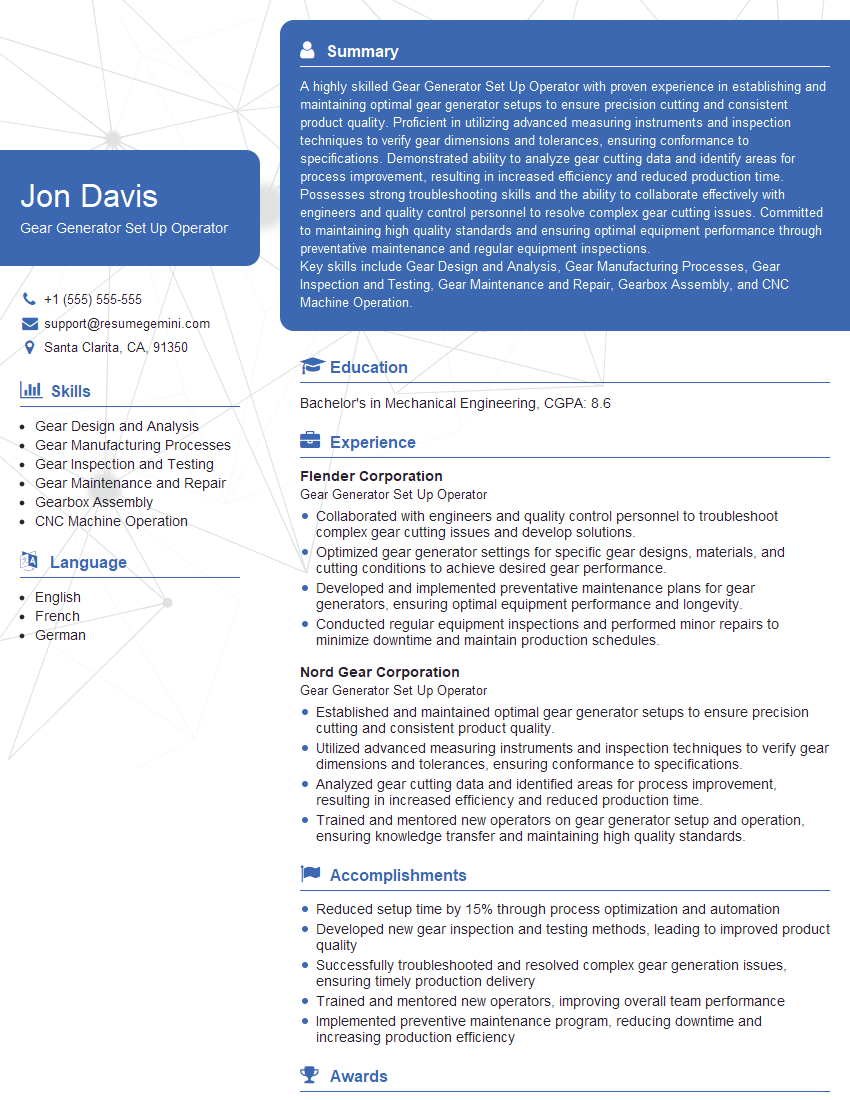

Jon Davis

Gear Generator Set Up Operator

Summary

A highly skilled Gear Generator Set Up Operator with proven experience in establishing and maintaining optimal gear generator setups to ensure precision cutting and consistent product quality. Proficient in utilizing advanced measuring instruments and inspection techniques to verify gear dimensions and tolerances, ensuring conformance to specifications. Demonstrated ability to analyze gear cutting data and identify areas for process improvement, resulting in increased efficiency and reduced production time. Possesses strong troubleshooting skills and the ability to collaborate effectively with engineers and quality control personnel to resolve complex gear cutting issues. Committed to maintaining high quality standards and ensuring optimal equipment performance through preventative maintenance and regular equipment inspections.

Key skills include Gear Design and Analysis, Gear Manufacturing Processes, Gear Inspection and Testing, Gear Maintenance and Repair, Gearbox Assembly, and CNC Machine Operation.

Education

Bachelor’s in Mechanical Engineering

October 2016

Skills

- Gear Design and Analysis

- Gear Manufacturing Processes

- Gear Inspection and Testing

- Gear Maintenance and Repair

- Gearbox Assembly

- CNC Machine Operation

Work Experience

Gear Generator Set Up Operator

- Collaborated with engineers and quality control personnel to troubleshoot complex gear cutting issues and develop solutions.

- Optimized gear generator settings for specific gear designs, materials, and cutting conditions to achieve desired gear performance.

- Developed and implemented preventative maintenance plans for gear generators, ensuring optimal equipment performance and longevity.

- Conducted regular equipment inspections and performed minor repairs to minimize downtime and maintain production schedules.

Gear Generator Set Up Operator

- Established and maintained optimal gear generator setups to ensure precision cutting and consistent product quality.

- Utilized advanced measuring instruments and inspection techniques to verify gear dimensions and tolerances, ensuring conformance to specifications.

- Analyzed gear cutting data and identified areas for process improvement, resulting in increased efficiency and reduced production time.

- Trained and mentored new operators on gear generator setup and operation, ensuring knowledge transfer and maintaining high quality standards.

Accomplishments

- Reduced setup time by 15% through process optimization and automation

- Developed new gear inspection and testing methods, leading to improved product quality

- Successfully troubleshooted and resolved complex gear generation issues, ensuring timely production delivery

- Trained and mentored new operators, improving overall team performance

- Implemented preventive maintenance program, reducing downtime and increasing production efficiency

Awards

- Employee of the Quarter for outstanding performance in gear generator setup and operation

- Recognized for achieving 99.5% accuracy in gear quality control

- Received Excellence Award for innovative gear setup techniques

Certificates

- Certified Gear Generator Operator

- ISO 9001 Certification

- ASME B6 Standard Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Generator Set Up Operator

- Highlight your experience and skills in gear design, analysis, and manufacturing processes.

- Quantify your accomplishments with specific metrics to demonstrate your impact on quality, efficiency, and productivity.

- Showcase your problem-solving abilities and provide examples of how you have successfully resolved complex gear cutting issues.

- Emphasize your commitment to quality and safety, and highlight any relevant certifications or training you have received.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Gear Generator Set Up Operator Resume

- Established and maintained optimal gear generator setups to ensure precision cutting and consistent product quality.

- Utilized advanced measuring instruments and inspection techniques to verify gear dimensions and tolerances, ensuring conformance to specifications.

- Analyzed gear cutting data and identified areas for process improvement, resulting in increased efficiency and reduced production time.

- Trained and mentored new operators on gear generator setup and operation, ensuring knowledge transfer and maintaining high quality standards.

- Collaborated with engineers and quality control personnel to troubleshoot complex gear cutting issues and develop solutions.

- Optimized gear generator settings for specific gear designs, materials, and cutting conditions to achieve desired gear performance.

- Developed and implemented preventative maintenance plans for gear generators, ensuring optimal equipment performance and longevity.

- Conducted regular equipment inspections and performed minor repairs to minimize downtime and maintain production schedules.

Frequently Asked Questions (FAQ’s) For Gear Generator Set Up Operator

What are the key responsibilities of a Gear Generator Set Up Operator?

The key responsibilities of a Gear Generator Set Up Operator include establishing and maintaining optimal gear generator setups, verifying gear dimensions and tolerances, analyzing gear cutting data for process improvement, training new operators, collaborating with engineers and quality control personnel to troubleshoot issues, optimizing gear generator settings, developing preventative maintenance plans, and conducting regular equipment inspections.

What skills are required to be a successful Gear Generator Set Up Operator?

To be a successful Gear Generator Set Up Operator, you typically need skills in Gear Design and Analysis, Gear Manufacturing Processes, Gear Inspection and Testing, Gear Maintenance and Repair, Gearbox Assembly, and CNC Machine Operation.

What is the average salary for a Gear Generator Set Up Operator?

The average salary for a Gear Generator Set Up Operator in the United States is around $60,000 per year.

What are the career prospects for a Gear Generator Set Up Operator?

Gear Generator Set Up Operators with experience and expertise can advance to roles such as Gear Manufacturing Supervisor, Quality Control Manager, or Production Manager.

What is the job outlook for a Gear Generator Set Up Operator?

The job outlook for Gear Generator Set Up Operators is expected to be positive in the coming years due to the increasing demand for precision-machined gears in various industries.

What are some tips for writing a standout Gear Generator Set Up Operator resume?

To write a standout Gear Generator Set Up Operator resume, highlight your experience and skills in gear design, analysis, and manufacturing processes, quantify your accomplishments with specific metrics, showcase your problem-solving abilities, emphasize your commitment to quality and safety, and proofread your resume carefully for any errors.

What are the common challenges faced by Gear Generator Set Up Operators?

Common challenges faced by Gear Generator Set Up Operators include ensuring precision cutting and consistent product quality, maintaining optimal equipment performance, troubleshooting complex gear cutting issues, and keeping up with advancements in gear manufacturing technology.