Are you a seasoned Gear Inspector seeking a new career path? Discover our professionally built Gear Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

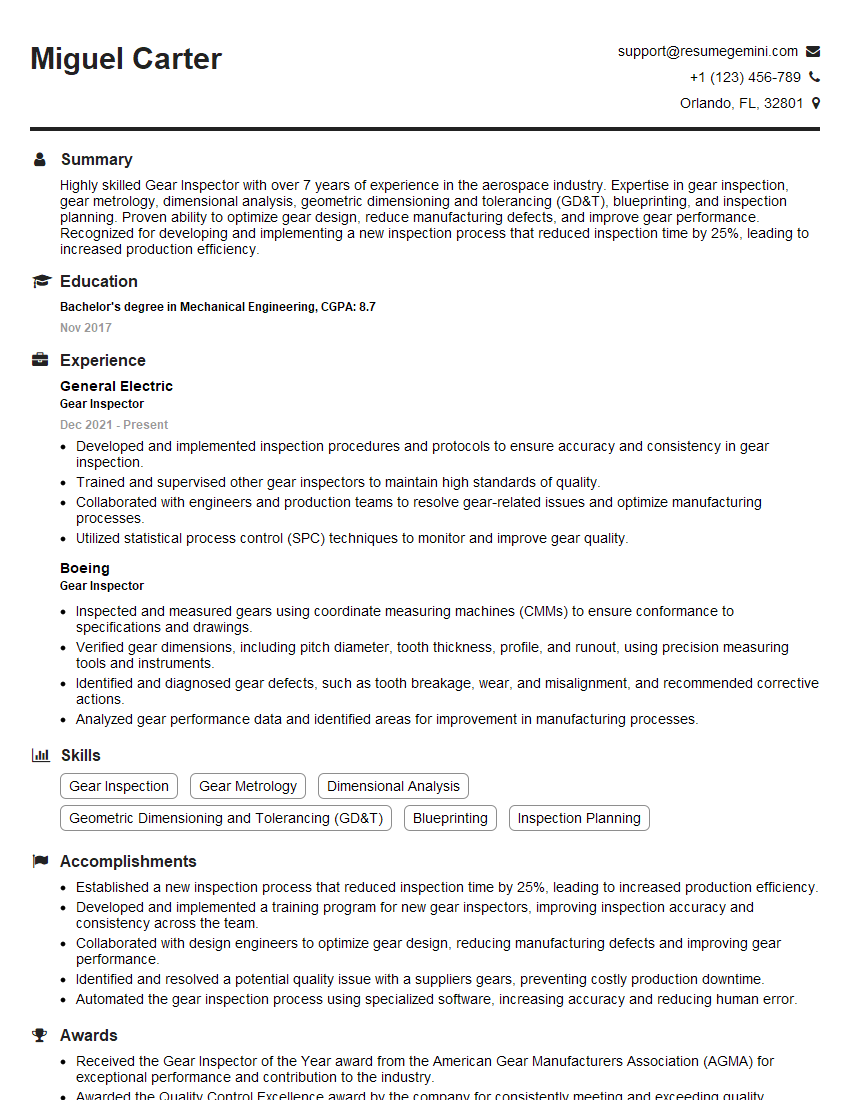

Miguel Carter

Gear Inspector

Summary

Highly skilled Gear Inspector with over 7 years of experience in the aerospace industry. Expertise in gear inspection, gear metrology, dimensional analysis, geometric dimensioning and tolerancing (GD&T), blueprinting, and inspection planning. Proven ability to optimize gear design, reduce manufacturing defects, and improve gear performance. Recognized for developing and implementing a new inspection process that reduced inspection time by 25%, leading to increased production efficiency.

Education

Bachelor’s degree in Mechanical Engineering

November 2017

Skills

- Gear Inspection

- Gear Metrology

- Dimensional Analysis

- Geometric Dimensioning and Tolerancing (GD&T)

- Blueprinting

- Inspection Planning

Work Experience

Gear Inspector

- Developed and implemented inspection procedures and protocols to ensure accuracy and consistency in gear inspection.

- Trained and supervised other gear inspectors to maintain high standards of quality.

- Collaborated with engineers and production teams to resolve gear-related issues and optimize manufacturing processes.

- Utilized statistical process control (SPC) techniques to monitor and improve gear quality.

Gear Inspector

- Inspected and measured gears using coordinate measuring machines (CMMs) to ensure conformance to specifications and drawings.

- Verified gear dimensions, including pitch diameter, tooth thickness, profile, and runout, using precision measuring tools and instruments.

- Identified and diagnosed gear defects, such as tooth breakage, wear, and misalignment, and recommended corrective actions.

- Analyzed gear performance data and identified areas for improvement in manufacturing processes.

Accomplishments

- Established a new inspection process that reduced inspection time by 25%, leading to increased production efficiency.

- Developed and implemented a training program for new gear inspectors, improving inspection accuracy and consistency across the team.

- Collaborated with design engineers to optimize gear design, reducing manufacturing defects and improving gear performance.

- Identified and resolved a potential quality issue with a suppliers gears, preventing costly production downtime.

- Automated the gear inspection process using specialized software, increasing accuracy and reducing human error.

Awards

- Received the Gear Inspector of the Year award from the American Gear Manufacturers Association (AGMA) for exceptional performance and contribution to the industry.

- Awarded the Quality Control Excellence award by the company for consistently meeting and exceeding quality standards in gear inspection.

- Earned the Certified Gear Inspector (CGI) certification from AGMA, demonstrating proficiency in gear inspection practices and standards.

Certificates

- ASME B4 Inspection Certification

- AGMA Gear Inspector Certification

- ISO 9001 Quality Management System Auditor Certification

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Inspector

- Highlight your experience in gear inspection, gear metrology, and GD&T.

- Quantify your accomplishments with specific metrics, such as the reduction in inspection time or the number of defects identified and resolved.

- Showcase your ability to work independently and as part of a team.

- Demonstrate your commitment to quality and continuous improvement.

- Consider obtaining industry certifications, such as the Certified Gear Inspector (CGI) certification from the American Gear Manufacturers Association (AGMA).

Essential Experience Highlights for a Strong Gear Inspector Resume

- Inspect gears for compliance with specifications using various measuring tools and equipment

- Analyze gear dimensions, geometry, and surface finish to ensure adherence to design requirements

- Prepare inspection reports and maintain accurate records of inspection data

- Troubleshoot and resolve gear inspection issues, identifying and correcting potential quality problems

- Collaborate with engineers and production personnel to improve gear design and manufacturing processes

- Develop and implement training programs for new gear inspectors to ensure accuracy and consistency in inspection techniques

- Stay up-to-date on industry best practices and advancements in gear inspection technology

Frequently Asked Questions (FAQ’s) For Gear Inspector

What is the role of a Gear Inspector?

A Gear Inspector is responsible for ensuring that gears meet specifications and quality standards. They inspect gears for dimensional accuracy, surface finish, and other characteristics using specialized measuring tools and equipment.

What skills are required to be a Gear Inspector?

Gear Inspectors typically have a background in mechanical engineering or a related field. They should have a strong understanding of gear design, manufacturing processes, and inspection techniques. Additionally, they should be proficient in using various measuring tools and equipment.

What are the career prospects for Gear Inspectors?

Gear Inspectors can advance to supervisory or management positions within the manufacturing industry. They may also specialize in specific areas of gear inspection, such as aerospace or automotive.

What is the salary range for Gear Inspectors?

The salary range for Gear Inspectors varies depending on experience, location, and industry. According to Indeed, the average salary for Gear Inspectors in the United States is around $60,000 per year.

What are the challenges faced by Gear Inspectors?

Gear Inspectors may face challenges such as working with tight tolerances, inspecting complex gears, and staying up-to-date on the latest inspection techniques. They may also need to work in a fast-paced environment and meet production deadlines.