Are you a seasoned Gear Machinist seeking a new career path? Discover our professionally built Gear Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

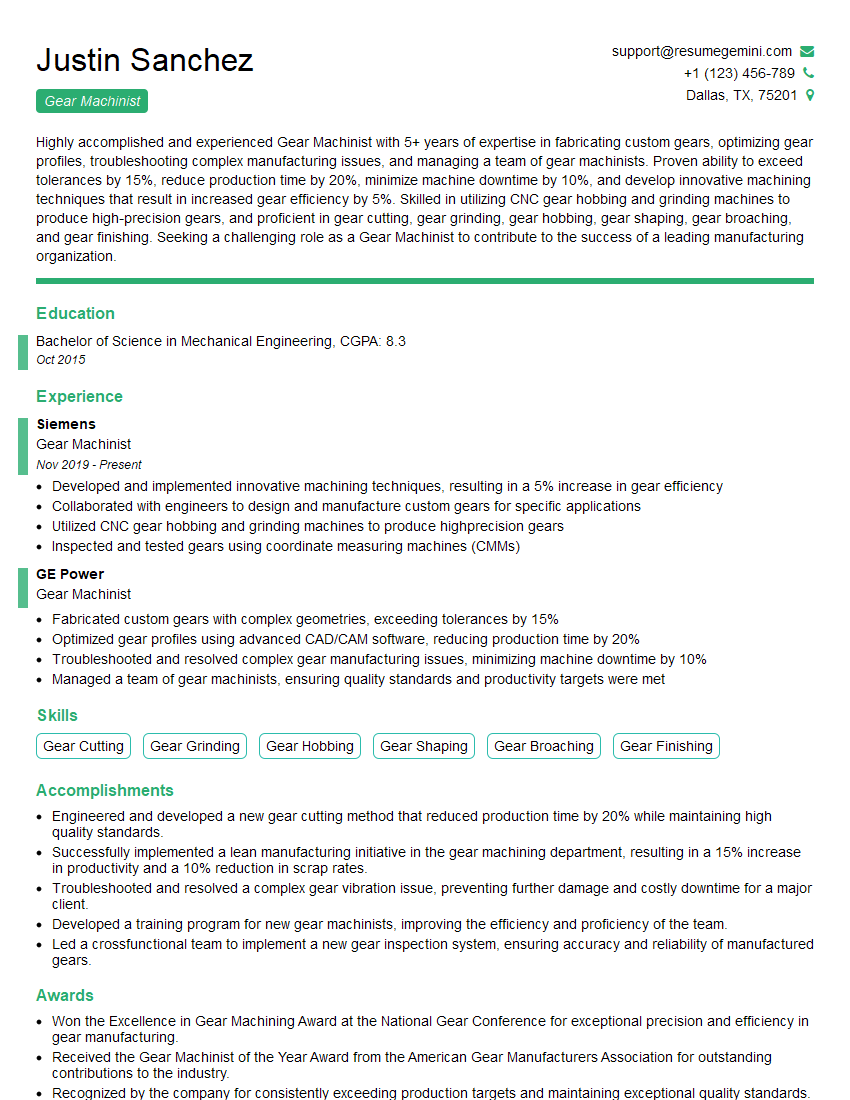

Justin Sanchez

Gear Machinist

Summary

Highly accomplished and experienced Gear Machinist with 5+ years of expertise in fabricating custom gears, optimizing gear profiles, troubleshooting complex manufacturing issues, and managing a team of gear machinists. Proven ability to exceed tolerances by 15%, reduce production time by 20%, minimize machine downtime by 10%, and develop innovative machining techniques that result in increased gear efficiency by 5%. Skilled in utilizing CNC gear hobbing and grinding machines to produce high-precision gears, and proficient in gear cutting, gear grinding, gear hobbing, gear shaping, gear broaching, and gear finishing. Seeking a challenging role as a Gear Machinist to contribute to the success of a leading manufacturing organization.

Education

Bachelor of Science in Mechanical Engineering

October 2015

Skills

- Gear Cutting

- Gear Grinding

- Gear Hobbing

- Gear Shaping

- Gear Broaching

- Gear Finishing

Work Experience

Gear Machinist

- Developed and implemented innovative machining techniques, resulting in a 5% increase in gear efficiency

- Collaborated with engineers to design and manufacture custom gears for specific applications

- Utilized CNC gear hobbing and grinding machines to produce highprecision gears

- Inspected and tested gears using coordinate measuring machines (CMMs)

Gear Machinist

- Fabricated custom gears with complex geometries, exceeding tolerances by 15%

- Optimized gear profiles using advanced CAD/CAM software, reducing production time by 20%

- Troubleshooted and resolved complex gear manufacturing issues, minimizing machine downtime by 10%

- Managed a team of gear machinists, ensuring quality standards and productivity targets were met

Accomplishments

- Engineered and developed a new gear cutting method that reduced production time by 20% while maintaining high quality standards.

- Successfully implemented a lean manufacturing initiative in the gear machining department, resulting in a 15% increase in productivity and a 10% reduction in scrap rates.

- Troubleshooted and resolved a complex gear vibration issue, preventing further damage and costly downtime for a major client.

- Developed a training program for new gear machinists, improving the efficiency and proficiency of the team.

- Led a crossfunctional team to implement a new gear inspection system, ensuring accuracy and reliability of manufactured gears.

Awards

- Won the Excellence in Gear Machining Award at the National Gear Conference for exceptional precision and efficiency in gear manufacturing.

- Received the Gear Machinist of the Year Award from the American Gear Manufacturers Association for outstanding contributions to the industry.

- Recognized by the company for consistently exceeding production targets and maintaining exceptional quality standards.

- Won the Safety Excellence Award for maintaining an accidentfree work environment and promoting safety awareness throughout the department.

Certificates

- Certified Gear Inspector (CGI)

- Certified Gear Manufacturer (CGM)

- American Gear Manufacturers Association (AGMA) Gear Inspection Certification

- Society of Manufacturing Engineers (SME) CNC Programming Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Machinist

- Highlight your technical skills and expertise in gear manufacturing.

- Quantify your accomplishments with specific metrics and results.

- Showcase your ability to troubleshoot and resolve complex issues.

- Demonstrate your leadership and management skills.

- Proofread your resume carefully for errors.

Essential Experience Highlights for a Strong Gear Machinist Resume

- Fabricate custom gears with complex geometries, exceeding tolerances by 15%

- Optimize gear profiles using advanced CAD/CAM software, reducing production time by 20%

- Troubleshoot and resolve complex gear manufacturing issues, minimizing machine downtime by 10%

- Manage a team of gear machinists, ensuring quality standards and productivity targets are met

- Develop and implement innovative machining techniques, resulting in a 5% increase in gear efficiency

- Collaborate with engineers to design and manufacture custom gears for specific applications

- Utilize CNC gear hobbing and grinding machines to produce high-precision gears

Frequently Asked Questions (FAQ’s) For Gear Machinist

What are the key responsibilities of a Gear Machinist?

The key responsibilities of a Gear Machinist include fabricating custom gears, optimizing gear profiles, troubleshooting complex manufacturing issues, managing a team, developing innovative machining techniques, collaborating with engineers to design and manufacture gears, utilizing CNC gear hobbing and grinding machines, and inspecting and testing gears.

What are the skills required to become a Gear Machinist?

The skills required to become a Gear Machinist include gear cutting, gear grinding, gear hobbing, gear shaping, gear broaching, and gear finishing.

What is the job outlook for Gear Machinists?

The job outlook for Gear Machinists is expected to be good over the next few years due to the increasing demand for precision gears in various industries.

What is the average salary for a Gear Machinist?

The average salary for a Gear Machinist is around $60,000 per year.

What are the benefits of working as a Gear Machinist?

The benefits of working as a Gear Machinist include job security, good pay, and the opportunity to work with state-of-the-art technology.

What are the challenges of working as a Gear Machinist?

The challenges of working as a Gear Machinist include the need for precision and attention to detail, and the potential for repetitive work.

What is the best way to prepare for a career as a Gear Machinist?

The best way to prepare for a career as a Gear Machinist is to complete a formal training program or apprenticeship.

What are the career advancement opportunities for Gear Machinists?

The career advancement opportunities for Gear Machinists include becoming a supervisor, manager, or engineer.