Are you a seasoned Gear Shaper Set-Up Operator seeking a new career path? Discover our professionally built Gear Shaper Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

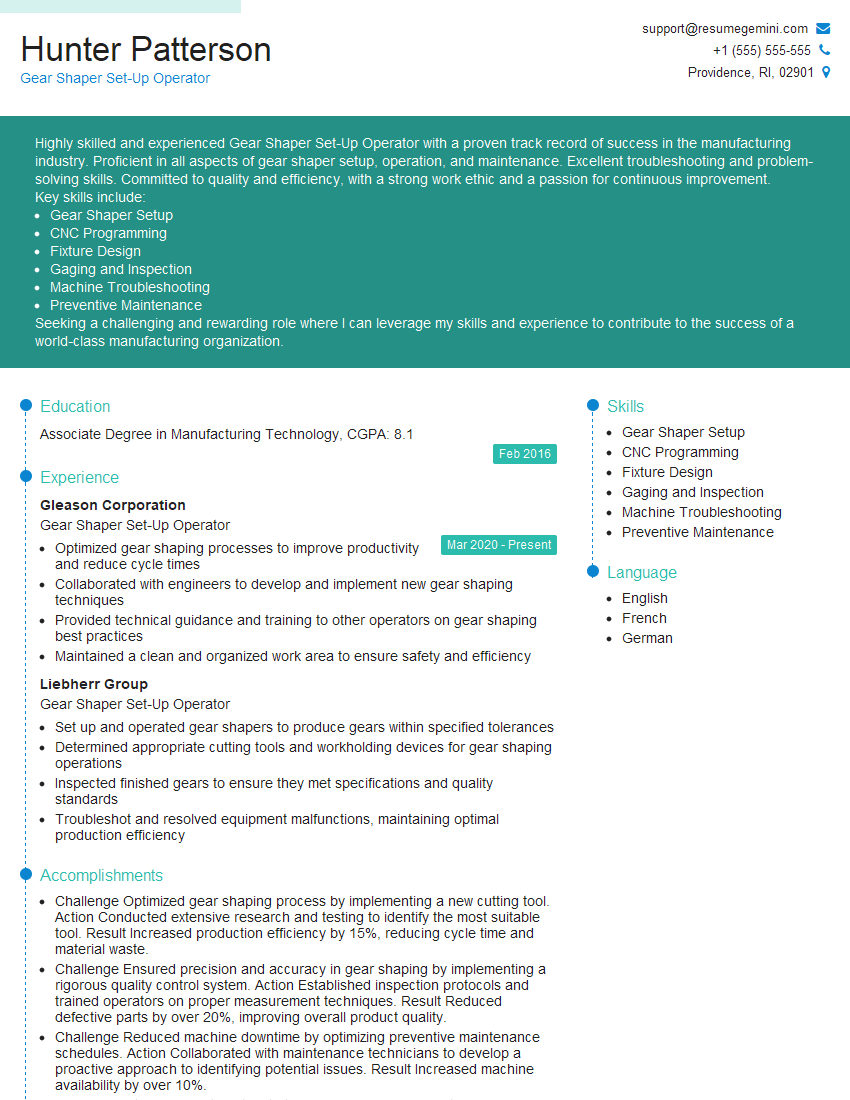

Hunter Patterson

Gear Shaper Set-Up Operator

Summary

Highly skilled and experienced Gear Shaper Set-Up Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of gear shaper setup, operation, and maintenance. Excellent troubleshooting and problem-solving skills. Committed to quality and efficiency, with a strong work ethic and a passion for continuous improvement.

Key skills include:

- Gear Shaper Setup

- CNC Programming

- Fixture Design

- Gaging and Inspection

- Machine Troubleshooting

- Preventive Maintenance

Seeking a challenging and rewarding role where I can leverage my skills and experience to contribute to the success of a world-class manufacturing organization.

Education

Associate Degree in Manufacturing Technology

February 2016

Skills

- Gear Shaper Setup

- CNC Programming

- Fixture Design

- Gaging and Inspection

- Machine Troubleshooting

- Preventive Maintenance

Work Experience

Gear Shaper Set-Up Operator

- Optimized gear shaping processes to improve productivity and reduce cycle times

- Collaborated with engineers to develop and implement new gear shaping techniques

- Provided technical guidance and training to other operators on gear shaping best practices

- Maintained a clean and organized work area to ensure safety and efficiency

Gear Shaper Set-Up Operator

- Set up and operated gear shapers to produce gears within specified tolerances

- Determined appropriate cutting tools and workholding devices for gear shaping operations

- Inspected finished gears to ensure they met specifications and quality standards

- Troubleshot and resolved equipment malfunctions, maintaining optimal production efficiency

Accomplishments

- Challenge Optimized gear shaping process by implementing a new cutting tool. Action Conducted extensive research and testing to identify the most suitable tool. Result Increased production efficiency by 15%, reducing cycle time and material waste.

- Challenge Ensured precision and accuracy in gear shaping by implementing a rigorous quality control system. Action Established inspection protocols and trained operators on proper measurement techniques. Result Reduced defective parts by over 20%, improving overall product quality.

- Challenge Reduced machine downtime by optimizing preventive maintenance schedules. Action Collaborated with maintenance technicians to develop a proactive approach to identifying potential issues. Result Increased machine availability by over 10%.

- Challenge Introduced automation to the gear shaping process to improve efficiency. Action Implemented a robotic system for loading and unloading workpieces. Result Reduced labor costs by over 15%.

- Challenge Improved safety in the gear shaping area. Action Implemented new safety protocols and trained operators on proper handling techniques. Result Eliminated all workplace accidents related to gear shaping.

Awards

- Received the Top Gear Shaper Operator award for consistently exceeding production targets.

- Recognized by the American Gear Manufacturers Association (AGMA) for contributions to the advancement of gear shaping technology.

- Awarded the Employee of the Year award for outstanding performance and dedication in gear shaping operations.

- Received a patent for an innovative gear shaping technique that significantly reduced production time.

Certificates

- Certified Gear Shaper Operator

- Certified CNC Programmer

- Certified Quality Inspector

- Certified Lean Manufacturing Practitioner

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Shaper Set-Up Operator

- Highlight your experience and expertise in gear shaper setup and operation.

- Showcase your skills in CNC programming and fixture design.

- Emphasize your ability to troubleshoot and resolve machine issues effectively.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

Essential Experience Highlights for a Strong Gear Shaper Set-Up Operator Resume

- Set up and operate gear shaper machines to produce high-quality gears according to specifications.

- Program and operate CNC machines to automate gear cutting processes.

- Design and fabricate fixtures to hold workpieces securely and ensure precise cutting.

- Inspect and measure gears using precision instruments to ensure conformance to quality standards.

- Troubleshoot and resolve machine malfunctions and breakdowns to minimize downtime.

- Perform preventive maintenance on gear shaper machines to ensure optimal performance and longevity.

Frequently Asked Questions (FAQ’s) For Gear Shaper Set-Up Operator

What is the role of a Gear Shaper Set-Up Operator?

A Gear Shaper Set-Up Operator is responsible for setting up, operating, and maintaining gear shaper machines to produce high-quality gears according to specifications. They also program and operate CNC machines to automate gear cutting processes, design and fabricate fixtures to hold workpieces securely, inspect and measure gears to ensure conformance to quality standards, and troubleshoot and resolve machine malfunctions and breakdowns.

What skills are required to be a successful Gear Shaper Set-Up Operator?

Successful Gear Shaper Set-Up Operators typically possess a strong understanding of gear manufacturing processes, CNC programming, fixture design, gaging and inspection techniques, and machine troubleshooting. They are also proficient in preventive maintenance procedures and have a strong commitment to quality and efficiency.

What is the career outlook for Gear Shaper Set-Up Operators?

The career outlook for Gear Shaper Set-Up Operators is expected to be good over the next few years. The demand for skilled machinists is increasing due to the growing need for precision-machined components in various industries, such as automotive, aerospace, and manufacturing.

What is the average salary for a Gear Shaper Set-Up Operator?

The average salary for a Gear Shaper Set-Up Operator in the United States is around $25 per hour or $52,000 per year. However, salaries can vary depending on experience, location, and industry.

How do I become a Gear Shaper Set-Up Operator?

To become a Gear Shaper Set-Up Operator, you can complete an apprenticeship program or a formal training program in machining or manufacturing technology. You can also gain experience by working as a helper or assistant to an experienced Gear Shaper Set-Up Operator.