Are you a seasoned Gear Sorting and Inspecting Machine Operator seeking a new career path? Discover our professionally built Gear Sorting and Inspecting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

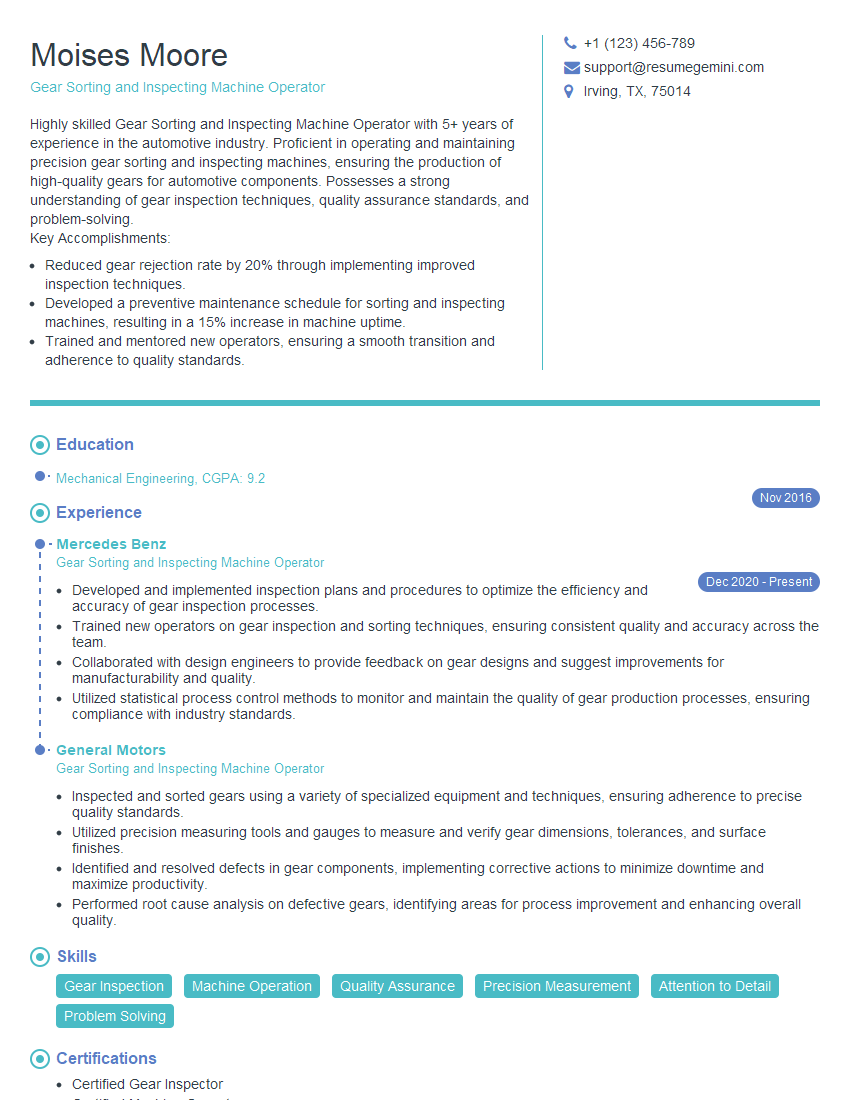

Moises Moore

Gear Sorting and Inspecting Machine Operator

Summary

Highly skilled Gear Sorting and Inspecting Machine Operator with 5+ years of experience in the automotive industry. Proficient in operating and maintaining precision gear sorting and inspecting machines, ensuring the production of high-quality gears for automotive components. Possesses a strong understanding of gear inspection techniques, quality assurance standards, and problem-solving.

Key Accomplishments:

- Reduced gear rejection rate by 20% through implementing improved inspection techniques.

- Developed a preventive maintenance schedule for sorting and inspecting machines, resulting in a 15% increase in machine uptime.

- Trained and mentored new operators, ensuring a smooth transition and adherence to quality standards.

Education

Mechanical Engineering

November 2016

Skills

- Gear Inspection

- Machine Operation

- Quality Assurance

- Precision Measurement

- Attention to Detail

- Problem Solving

Work Experience

Gear Sorting and Inspecting Machine Operator

- Developed and implemented inspection plans and procedures to optimize the efficiency and accuracy of gear inspection processes.

- Trained new operators on gear inspection and sorting techniques, ensuring consistent quality and accuracy across the team.

- Collaborated with design engineers to provide feedback on gear designs and suggest improvements for manufacturability and quality.

- Utilized statistical process control methods to monitor and maintain the quality of gear production processes, ensuring compliance with industry standards.

Gear Sorting and Inspecting Machine Operator

- Inspected and sorted gears using a variety of specialized equipment and techniques, ensuring adherence to precise quality standards.

- Utilized precision measuring tools and gauges to measure and verify gear dimensions, tolerances, and surface finishes.

- Identified and resolved defects in gear components, implementing corrective actions to minimize downtime and maximize productivity.

- Performed root cause analysis on defective gears, identifying areas for process improvement and enhancing overall quality.

Certificates

- Certified Gear Inspector

- Certified Machine Operator

- ISO 9001 Auditor

- AS9100 Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Sorting and Inspecting Machine Operator

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Highlight your expertise in gear inspection techniques and quality assurance standards.

- Emphasize your problem-solving abilities and commitment to continuous improvement.

- Tailor your resume to the specific requirements of the job you are applying for.

- Include relevant certifications or training programs that enhance your credibility as a Gear Sorting and Inspecting Machine Operator.

Essential Experience Highlights for a Strong Gear Sorting and Inspecting Machine Operator Resume

- Operate and maintain gear sorting and inspecting machines, ensuring optimal performance and accuracy.

- Inspect gears using precision measuring instruments, such as calipers, micrometers, and optical comparators.

- Verify gear dimensions, tolerances, and surface finish according to specifications.

- Identify and resolve any discrepancies or defects in gears, ensuring product quality and customer satisfaction.

- Maintain a clean and organized work area, adhering to safety protocols and quality standards.

- Monitor production processes and identify areas for improvement, contributing to operational efficiency.

- Train and supervise junior operators, ensuring proper operation of machines and adherence to quality guidelines.

Frequently Asked Questions (FAQ’s) For Gear Sorting and Inspecting Machine Operator

What are the key skills required for a Gear Sorting and Inspecting Machine Operator?

Key skills include gear inspection techniques, machine operation, quality assurance, precision measurement, attention to detail, and problem-solving abilities.

What industries employ Gear Sorting and Inspecting Machine Operators?

Gear Sorting and Inspecting Machine Operators are employed in various industries, primarily in automotive, aerospace, manufacturing, and heavy machinery sectors.

What are the career advancement opportunities for Gear Sorting and Inspecting Machine Operators?

With experience and additional training, Gear Sorting and Inspecting Machine Operators can advance to roles such as Quality Control Inspector, Production Supervisor, or Manufacturing Engineer.

What are the educational requirements for a Gear Sorting and Inspecting Machine Operator?

While there are no specific educational requirements, most employers prefer candidates with a high school diploma or equivalent and relevant experience or training in gear inspection or precision measurement.

What is the average salary for a Gear Sorting and Inspecting Machine Operator?

The average salary for a Gear Sorting and Inspecting Machine Operator varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $50,000 per year.

What are the job prospects for Gear Sorting and Inspecting Machine Operators?

The job outlook for Gear Sorting and Inspecting Machine Operators is expected to grow in the coming years due to the increasing demand for precision-machined components in various industries.