Are you a seasoned Glost Kiln Operator seeking a new career path? Discover our professionally built Glost Kiln Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

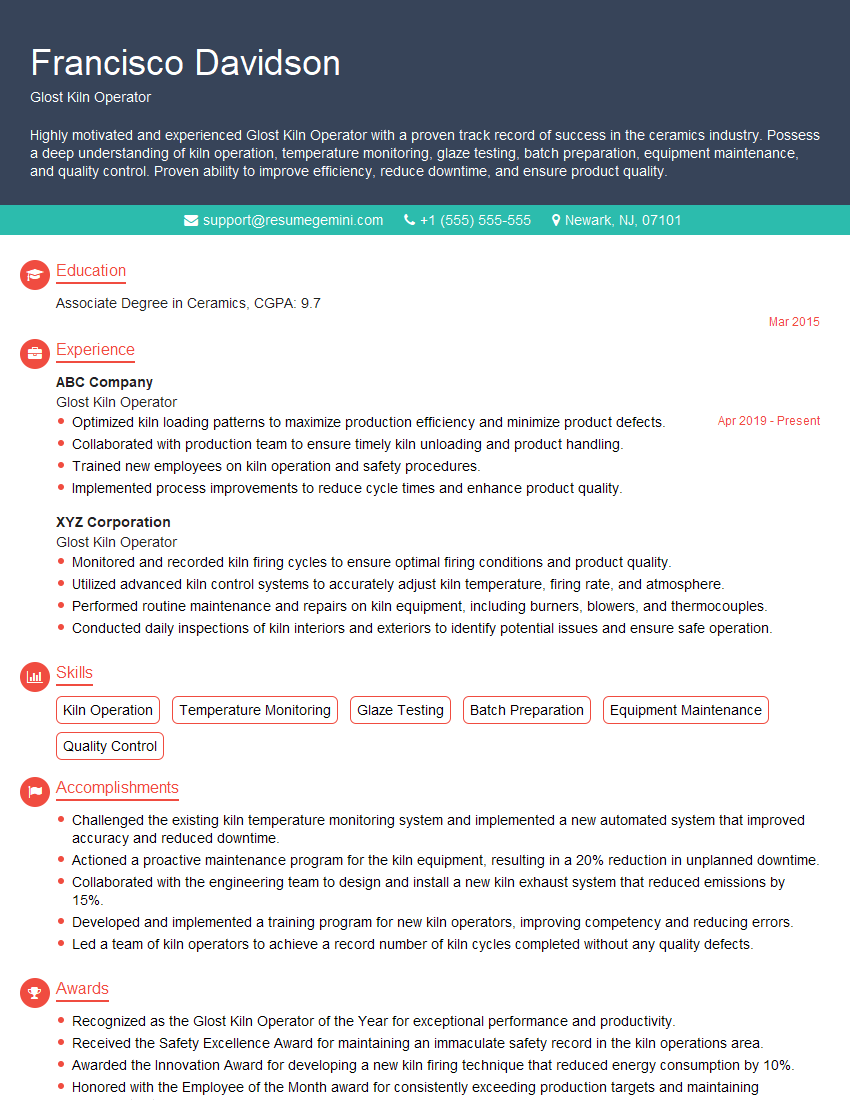

Francisco Davidson

Glost Kiln Operator

Summary

Highly motivated and experienced Glost Kiln Operator with a proven track record of success in the ceramics industry. Possess a deep understanding of kiln operation, temperature monitoring, glaze testing, batch preparation, equipment maintenance, and quality control. Proven ability to improve efficiency, reduce downtime, and ensure product quality.

Education

Associate Degree in Ceramics

March 2015

Skills

- Kiln Operation

- Temperature Monitoring

- Glaze Testing

- Batch Preparation

- Equipment Maintenance

- Quality Control

Work Experience

Glost Kiln Operator

- Optimized kiln loading patterns to maximize production efficiency and minimize product defects.

- Collaborated with production team to ensure timely kiln unloading and product handling.

- Trained new employees on kiln operation and safety procedures.

- Implemented process improvements to reduce cycle times and enhance product quality.

Glost Kiln Operator

- Monitored and recorded kiln firing cycles to ensure optimal firing conditions and product quality.

- Utilized advanced kiln control systems to accurately adjust kiln temperature, firing rate, and atmosphere.

- Performed routine maintenance and repairs on kiln equipment, including burners, blowers, and thermocouples.

- Conducted daily inspections of kiln interiors and exteriors to identify potential issues and ensure safe operation.

Accomplishments

- Challenged the existing kiln temperature monitoring system and implemented a new automated system that improved accuracy and reduced downtime.

- Actioned a proactive maintenance program for the kiln equipment, resulting in a 20% reduction in unplanned downtime.

- Collaborated with the engineering team to design and install a new kiln exhaust system that reduced emissions by 15%.

- Developed and implemented a training program for new kiln operators, improving competency and reducing errors.

- Led a team of kiln operators to achieve a record number of kiln cycles completed without any quality defects.

Awards

- Recognized as the Glost Kiln Operator of the Year for exceptional performance and productivity.

- Received the Safety Excellence Award for maintaining an immaculate safety record in the kiln operations area.

- Awarded the Innovation Award for developing a new kiln firing technique that reduced energy consumption by 10%.

- Honored with the Employee of the Month award for consistently exceeding production targets and maintaining highquality standards.

Certificates

- Certified Kiln Operator

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Glost Kiln Operator

- Highlight your experience and skills in kiln operation and maintenance.

- Quantify your accomplishments and provide specific examples of how you improved efficiency or reduced downtime.

- Showcase your knowledge of glaze testing and batch preparation.

- Emphasize your commitment to quality control and continuous improvement.

Essential Experience Highlights for a Strong Glost Kiln Operator Resume

- Operate and monitor glost kilns to ensure proper firing of ceramic products.

- Conduct regular inspections and maintenance of kilns and related equipment.

- Monitor and adjust kiln temperature and atmosphere to achieve desired results.

- Prepare and test glaze materials to ensure consistent quality and color.

- Maintain accurate records of kiln operations and product quality.

- Troubleshoot and resolve kiln malfunctions and equipment issues.

- Collaborate with other departments to optimize production processes and improve product quality.

Frequently Asked Questions (FAQ’s) For Glost Kiln Operator

What is the role of a Glost Kiln Operator?

A Glost Kiln Operator is responsible for operating and maintaining glost kilns to ensure the proper firing of ceramic products.

What are the key skills required for a Glost Kiln Operator?

Key skills include kiln operation, temperature monitoring, glaze testing, batch preparation, equipment maintenance, and quality control.

What is the work environment of a Glost Kiln Operator like?

Glost Kiln Operators typically work in manufacturing facilities, often in close proximity to kilns and other equipment.

What is the career outlook for Glost Kiln Operators?

The career outlook is expected to be good, with increased demand for ceramic products in various industries.

What are the potential career advancement opportunities for Glost Kiln Operators?

With experience and additional training, Glost Kiln Operators can advance to roles such as Kiln Supervisor or Production Manager.