Are you a seasoned Glucose and Syrup Weigher seeking a new career path? Discover our professionally built Glucose and Syrup Weigher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

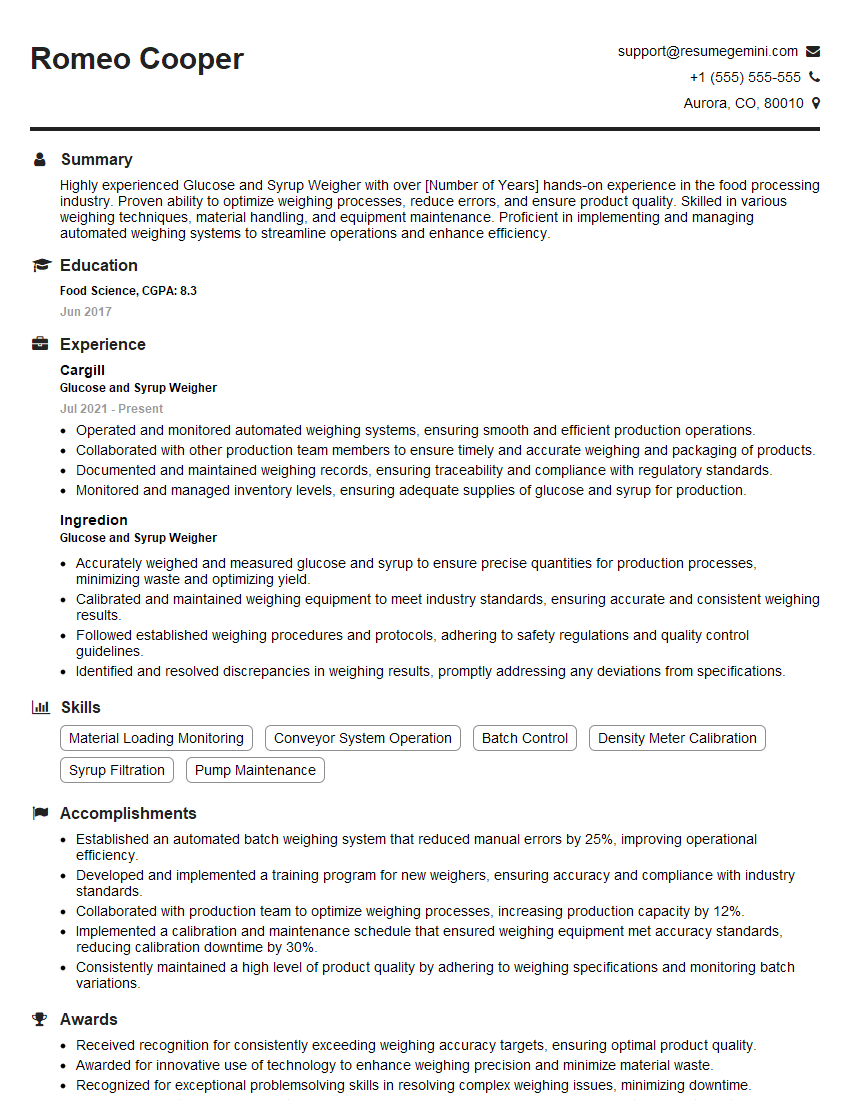

Romeo Cooper

Glucose and Syrup Weigher

Summary

Highly experienced Glucose and Syrup Weigher with over [Number of Years] hands-on experience in the food processing industry. Proven ability to optimize weighing processes, reduce errors, and ensure product quality. Skilled in various weighing techniques, material handling, and equipment maintenance. Proficient in implementing and managing automated weighing systems to streamline operations and enhance efficiency.

Education

Food Science

June 2017

Skills

- Material Loading Monitoring

- Conveyor System Operation

- Batch Control

- Density Meter Calibration

- Syrup Filtration

- Pump Maintenance

Work Experience

Glucose and Syrup Weigher

- Operated and monitored automated weighing systems, ensuring smooth and efficient production operations.

- Collaborated with other production team members to ensure timely and accurate weighing and packaging of products.

- Documented and maintained weighing records, ensuring traceability and compliance with regulatory standards.

- Monitored and managed inventory levels, ensuring adequate supplies of glucose and syrup for production.

Glucose and Syrup Weigher

- Accurately weighed and measured glucose and syrup to ensure precise quantities for production processes, minimizing waste and optimizing yield.

- Calibrated and maintained weighing equipment to meet industry standards, ensuring accurate and consistent weighing results.

- Followed established weighing procedures and protocols, adhering to safety regulations and quality control guidelines.

- Identified and resolved discrepancies in weighing results, promptly addressing any deviations from specifications.

Accomplishments

- Established an automated batch weighing system that reduced manual errors by 25%, improving operational efficiency.

- Developed and implemented a training program for new weighers, ensuring accuracy and compliance with industry standards.

- Collaborated with production team to optimize weighing processes, increasing production capacity by 12%.

- Implemented a calibration and maintenance schedule that ensured weighing equipment met accuracy standards, reducing calibration downtime by 30%.

- Consistently maintained a high level of product quality by adhering to weighing specifications and monitoring batch variations.

Awards

- Received recognition for consistently exceeding weighing accuracy targets, ensuring optimal product quality.

- Awarded for innovative use of technology to enhance weighing precision and minimize material waste.

- Recognized for exceptional problemsolving skills in resolving complex weighing issues, minimizing downtime.

- Received a safety award for maintaining a clean and organized weighing area, adhering to all safety protocols.

Certificates

- OSHA Safety Training

- Forklift Certification

- HACCP Certification

- ISO 22000 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Glucose and Syrup Weigher

- Highlight your experience in automated weighing systems and process optimization to demonstrate your technical expertise.

- Quantify your accomplishments with specific metrics to showcase the impact of your contributions.

- Emphasize your ability to work effectively in a fast-paced production environment and manage multiple responsibilities.

- Include keywords such as “glucose weighing”, “syrup processing”, and “quality control” throughout your resume to enhance visibility.

Essential Experience Highlights for a Strong Glucose and Syrup Weigher Resume

- Monitor and control material loading, conveyor system operation, and batch control to ensure accurate weighing and product quality.

- Calibrate and maintain density meters, syrup filtration systems, and pumps to ensure equipment accuracy and reliability.

- Collaborate with production teams to optimize weighing processes and identify areas for improvement, resulting in increased production capacity and efficiency.

- Implement and maintain calibration and maintenance schedules for weighing equipment to ensure compliance with industry standards and minimize downtime.

- Monitor batch variations and adhere to weighing specifications to maintain product quality and consistency.

- Train and supervise new weighers to ensure accuracy and compliance with industry standards and company policies.

Frequently Asked Questions (FAQ’s) For Glucose and Syrup Weigher

What is the primary responsibility of a Glucose and Syrup Weigher?

The primary responsibility of a Glucose and Syrup Weigher is to accurately weigh and measure glucose and syrup during the production process to ensure the correct proportions for various products.

What skills are essential for success as a Glucose and Syrup Weigher?

Essential skills for success as a Glucose and Syrup Weigher include attention to detail, accuracy, knowledge of weighing techniques, equipment operation, and quality control procedures.

What are the career prospects for a Glucose and Syrup Weigher?

With experience and additional training, Glucose and Syrup Weighers can advance to positions such as Production Supervisor, Quality Control Inspector, or Process Engineer in the food processing industry.

What is the typical work environment for a Glucose and Syrup Weigher?

Glucose and Syrup Weighers typically work in food processing plants in production areas, which can involve exposure to noise, temperature fluctuations, and potential hazards.

What is the importance of accuracy in the role of a Glucose and Syrup Weigher?

Accuracy is crucial for Glucose and Syrup Weighers as incorrect weighing can impact product quality, consistency, and compliance with industry regulations, potentially leading to product recalls or safety concerns.