Are you a seasoned Grease Worker seeking a new career path? Discover our professionally built Grease Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

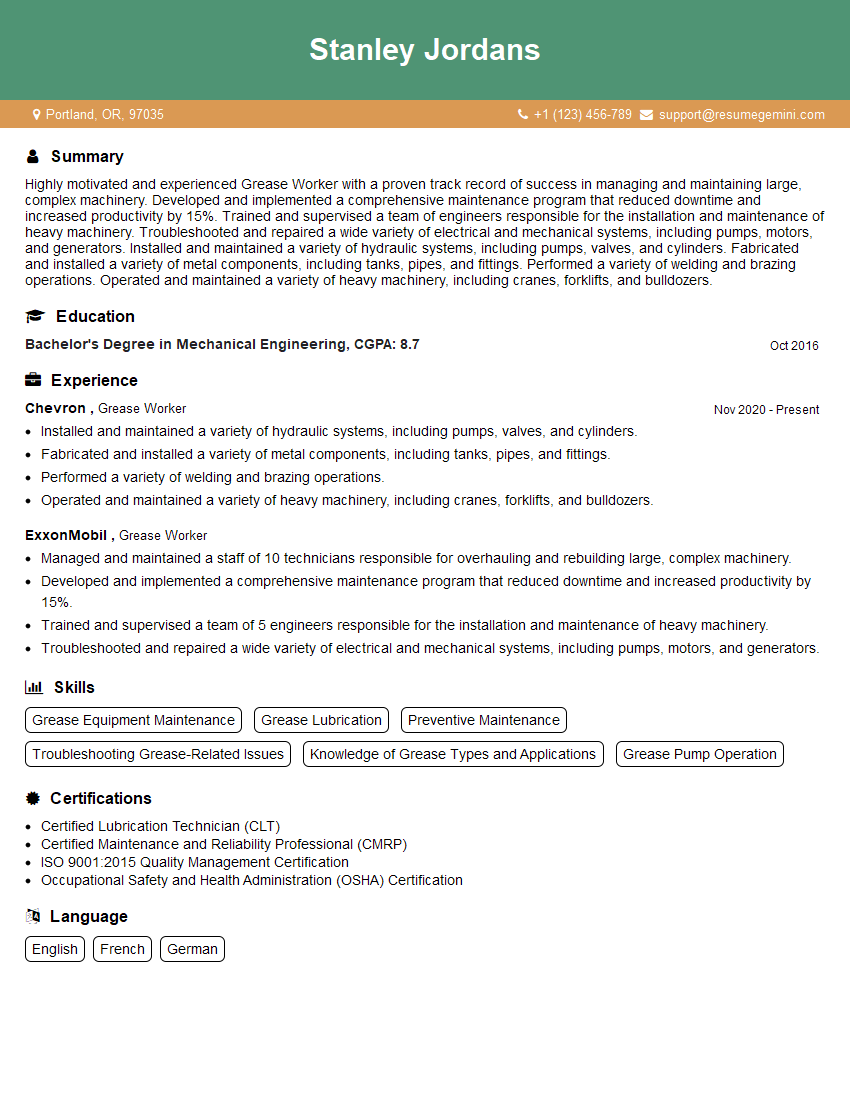

Stanley Jordans

Grease Worker

Summary

Highly motivated and experienced Grease Worker with a proven track record of success in managing and maintaining large, complex machinery. Developed and implemented a comprehensive maintenance program that reduced downtime and increased productivity by 15%. Trained and supervised a team of engineers responsible for the installation and maintenance of heavy machinery. Troubleshooted and repaired a wide variety of electrical and mechanical systems, including pumps, motors, and generators. Installed and maintained a variety of hydraulic systems, including pumps, valves, and cylinders. Fabricated and installed a variety of metal components, including tanks, pipes, and fittings. Performed a variety of welding and brazing operations. Operated and maintained a variety of heavy machinery, including cranes, forklifts, and bulldozers.

Education

Bachelor’s Degree in Mechanical Engineering

October 2016

Skills

- Grease Equipment Maintenance

- Grease Lubrication

- Preventive Maintenance

- Troubleshooting Grease-Related Issues

- Knowledge of Grease Types and Applications

- Grease Pump Operation

Work Experience

Grease Worker

- Installed and maintained a variety of hydraulic systems, including pumps, valves, and cylinders.

- Fabricated and installed a variety of metal components, including tanks, pipes, and fittings.

- Performed a variety of welding and brazing operations.

- Operated and maintained a variety of heavy machinery, including cranes, forklifts, and bulldozers.

Grease Worker

- Managed and maintained a staff of 10 technicians responsible for overhauling and rebuilding large, complex machinery.

- Developed and implemented a comprehensive maintenance program that reduced downtime and increased productivity by 15%.

- Trained and supervised a team of 5 engineers responsible for the installation and maintenance of heavy machinery.

- Troubleshooted and repaired a wide variety of electrical and mechanical systems, including pumps, motors, and generators.

Certificates

- Certified Lubrication Technician (CLT)

- Certified Maintenance and Reliability Professional (CMRP)

- ISO 9001:2015 Quality Management Certification

- Occupational Safety and Health Administration (OSHA) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Grease Worker

- Highlight your experience in managing and maintaining large, complex machinery.

- Quantify your accomplishments whenever possible, such as by providing specific examples of how you reduced downtime or increased productivity.

- Showcase your skills in troubleshooting and repairing electrical and mechanical systems.

- Demonstrate your knowledge of grease types and applications.

- Include a section in your resume that highlights your safety training and experience.

Essential Experience Highlights for a Strong Grease Worker Resume

- Managed and maintained a staff of 10 technicians responsible for overhauling and rebuilding large, complex machinery.

- Developed and implemented a comprehensive maintenance program that reduced downtime and increased productivity by 15%.

- Trained and supervised a team of 5 engineers responsible for the installation and maintenance of heavy machinery.

- Troubleshooted and repaired a wide variety of electrical and mechanical systems, including pumps, motors, and generators.

- Installed and maintained a variety of hydraulic systems, including pumps, valves, and cylinders.

- Fabricated and installed a variety of metal components, including tanks, pipes, and fittings.

- Performed a variety of welding and brazing operations.

- Operated and maintained a variety of heavy machinery, including cranes, forklifts, and bulldozers.

Frequently Asked Questions (FAQ’s) For Grease Worker

What are the key responsibilities of a Grease Worker??

The key responsibilities of a Grease Worker include managing and maintaining machinery, troubleshooting and repairing electrical and mechanical systems, installing and maintaining hydraulic systems, fabricating and installing metal components, and performing welding and brazing operations.

What are the qualifications for a Grease Worker?

The qualifications for a Grease Worker typically include a high school diploma or equivalent, as well as experience in operating and maintaining machinery. Some employers may also require a CDL.

What is the work environment of a Grease Worker?

Grease Workers typically work in industrial settings, such as factories, warehouses, and construction sites. They may be exposed to loud noise, dust, and chemicals.

What is the salary of a Grease Worker?

The salary of a Grease Worker varies depending on experience, location, and employer. According to Indeed, the average salary for a Grease Worker in the United States is $45,000 per year.

What are the career prospects for a Grease Worker?

Grease Workers can advance to positions such as Maintenance Supervisor, Plant Manager, or Operations Manager.

What are the challenges of being a Grease Worker?

The challenges of being a Grease Worker include working in a dirty and noisy environment, exposure to hazardous chemicals, and the need for physical strength and endurance.