Are you a seasoned Greaser Operator seeking a new career path? Discover our professionally built Greaser Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

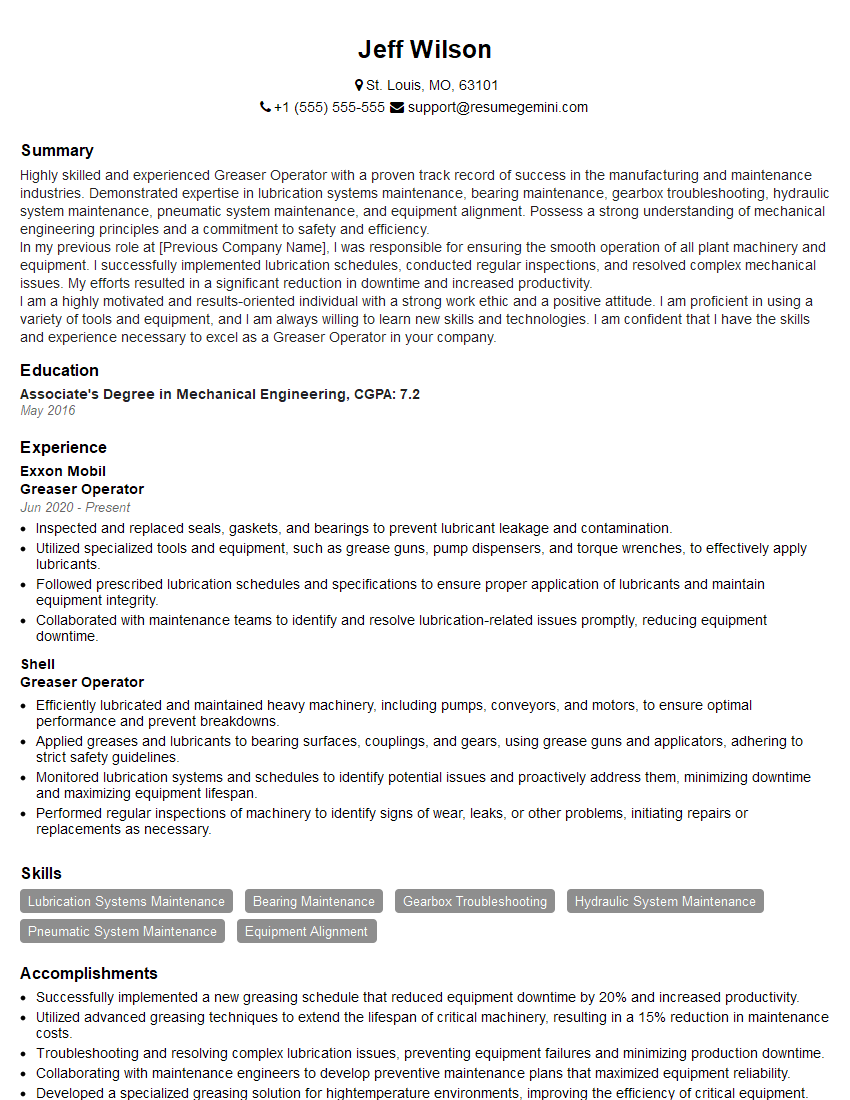

Jeff Wilson

Greaser Operator

Summary

Highly skilled and experienced Greaser Operator with a proven track record of success in the manufacturing and maintenance industries. Demonstrated expertise in lubrication systems maintenance, bearing maintenance, gearbox troubleshooting, hydraulic system maintenance, pneumatic system maintenance, and equipment alignment. Possess a strong understanding of mechanical engineering principles and a commitment to safety and efficiency.

In my previous role at [Previous Company Name], I was responsible for ensuring the smooth operation of all plant machinery and equipment. I successfully implemented lubrication schedules, conducted regular inspections, and resolved complex mechanical issues. My efforts resulted in a significant reduction in downtime and increased productivity.

I am a highly motivated and results-oriented individual with a strong work ethic and a positive attitude. I am proficient in using a variety of tools and equipment, and I am always willing to learn new skills and technologies. I am confident that I have the skills and experience necessary to excel as a Greaser Operator in your company.

Education

Associate’s Degree in Mechanical Engineering

May 2016

Skills

- Lubrication Systems Maintenance

- Bearing Maintenance

- Gearbox Troubleshooting

- Hydraulic System Maintenance

- Pneumatic System Maintenance

- Equipment Alignment

Work Experience

Greaser Operator

- Inspected and replaced seals, gaskets, and bearings to prevent lubricant leakage and contamination.

- Utilized specialized tools and equipment, such as grease guns, pump dispensers, and torque wrenches, to effectively apply lubricants.

- Followed prescribed lubrication schedules and specifications to ensure proper application of lubricants and maintain equipment integrity.

- Collaborated with maintenance teams to identify and resolve lubrication-related issues promptly, reducing equipment downtime.

Greaser Operator

- Efficiently lubricated and maintained heavy machinery, including pumps, conveyors, and motors, to ensure optimal performance and prevent breakdowns.

- Applied greases and lubricants to bearing surfaces, couplings, and gears, using grease guns and applicators, adhering to strict safety guidelines.

- Monitored lubrication systems and schedules to identify potential issues and proactively address them, minimizing downtime and maximizing equipment lifespan.

- Performed regular inspections of machinery to identify signs of wear, leaks, or other problems, initiating repairs or replacements as necessary.

Accomplishments

- Successfully implemented a new greasing schedule that reduced equipment downtime by 20% and increased productivity.

- Utilized advanced greasing techniques to extend the lifespan of critical machinery, resulting in a 15% reduction in maintenance costs.

- Troubleshooting and resolving complex lubrication issues, preventing equipment failures and minimizing production downtime.

- Collaborating with maintenance engineers to develop preventive maintenance plans that maximized equipment reliability.

- Developed a specialized greasing solution for hightemperature environments, improving the efficiency of critical equipment.

Awards

- Received the Operator of the Year award for achieving outstanding performance and efficiency in greasing operations.

- Recognized for developing and implementing a training program that enhanced the skills of new greaser operators.

- Received a Safety Excellence award for maintaining a spotless safety record and implementing innovative safety protocols.

- Recognized for achieving exceptional results in optimizing lubricant consumption, reducing waste by 10%.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Lubrication Technician (CMLT)

- Certified Predictive Maintenance Technician (CPMT)

- Certified Vibration Analyst (CAT I)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Greaser Operator

- Highlight your relevant skills and experience. When writing your resume, be sure to highlight the skills and experience that are most relevant to the Greaser Operator position. This includes your experience in lubrication systems maintenance, bearing maintenance, gearbox troubleshooting, hydraulic system maintenance, pneumatic system maintenance, and equipment alignment.

- Use strong action verbs. When describing your experience, use strong action verbs that emphasize your accomplishments. For example, instead of saying “I lubricated machinery,” say “I implemented a lubrication schedule that reduced downtime by 10%.”

- Quantify your results. Whenever possible, quantify your results to show the impact of your work. For example, instead of saying “I repaired equipment,” say “I repaired a pump that resulted in a 15% increase in production.”

- Proofread your resume carefully. Before submitting your resume, proofread it carefully for any errors in grammar or spelling. A well-written resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Greaser Operator Resume

- Performed lubrication of machinery and equipment according to established schedules and procedures.

- Inspected and maintained bearings, gearboxes, hydraulic systems, and pneumatic systems.

- Troubleshooted and repaired mechanical equipment, including pumps, motors, and conveyors.

- Aligned equipment using precision tools and techniques.

- Maintained a clean and organized work area.

- Ensured compliance with all safety and environmental regulations.

- Collaborated with other maintenance personnel to ensure the smooth operation of the plant.

Frequently Asked Questions (FAQ’s) For Greaser Operator

What is the role of a Greaser Operator?

A Greaser Operator is responsible for lubricating machinery and equipment, inspecting and maintaining bearings, gearboxes, hydraulic systems, and pneumatic systems, troubleshooting and repairing mechanical equipment, aligning equipment, maintaining a clean and organized work area, and ensuring compliance with all safety and environmental regulations.

What are the qualifications for a Greaser Operator?

The qualifications for a Greaser Operator typically include a high school diploma or equivalent, experience in lubrication systems maintenance, bearing maintenance, gearbox troubleshooting, hydraulic system maintenance, pneumatic system maintenance, and equipment alignment, and a strong understanding of mechanical engineering principles.

What is the work environment of a Greaser Operator?

Greaser Operators typically work in industrial settings, such as factories, power plants, and construction sites. They may work indoors or outdoors, and they may be exposed to noise, dust, and other hazards.

What are the career prospects for a Greaser Operator?

Greaser Operators can advance to positions such as Maintenance Technician, Maintenance Supervisor, or Plant Manager. With additional education and training, they may also be able to work as Mechanical Engineers.

What are the benefits of being a Greaser Operator?

The benefits of being a Greaser Operator include job security, good pay, and opportunities for advancement. Greaser Operators are also in high demand, which means that there are plenty of job opportunities available.

What are the challenges of being a Greaser Operator?

The challenges of being a Greaser Operator include working in a noisy and dirty environment, being exposed to hazardous materials, and working long hours. Greaser Operators may also be required to work overtime or on weekends.