Are you a seasoned Grinding Wheel Operator seeking a new career path? Discover our professionally built Grinding Wheel Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

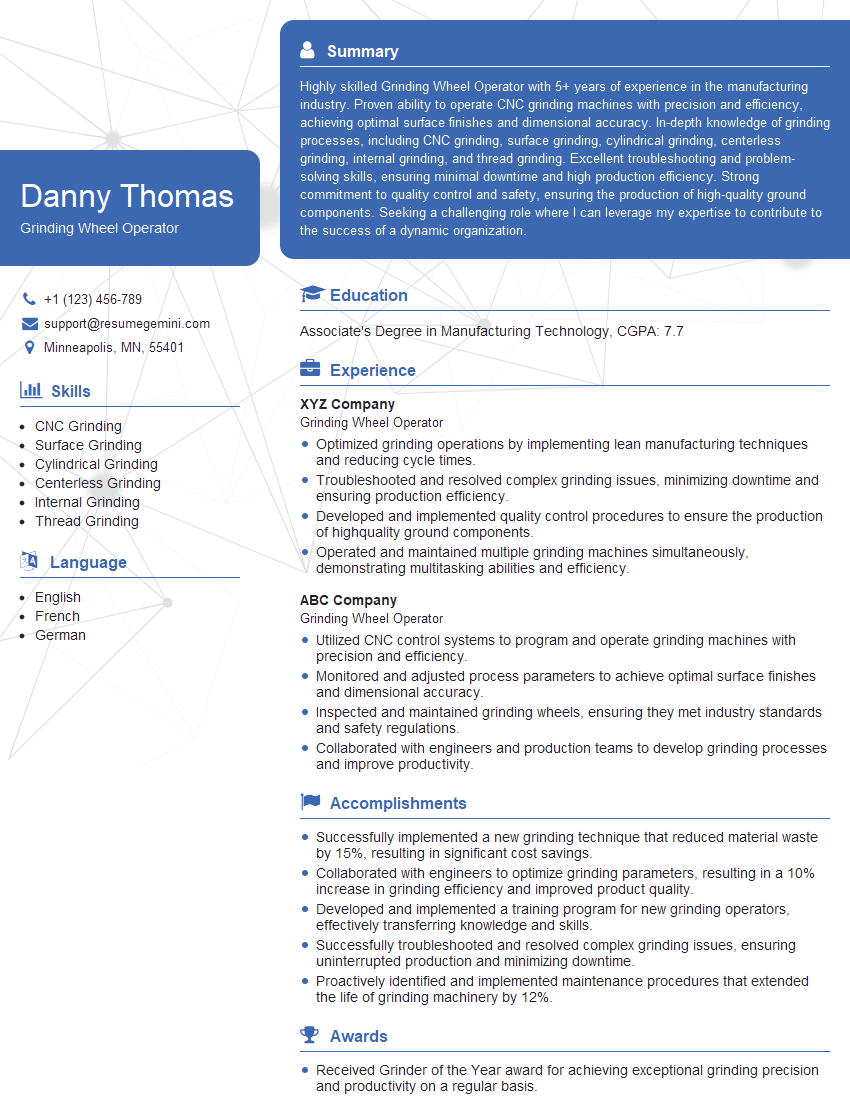

Danny Thomas

Grinding Wheel Operator

Summary

Highly skilled Grinding Wheel Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate CNC grinding machines with precision and efficiency, achieving optimal surface finishes and dimensional accuracy. In-depth knowledge of grinding processes, including CNC grinding, surface grinding, cylindrical grinding, centerless grinding, internal grinding, and thread grinding. Excellent troubleshooting and problem-solving skills, ensuring minimal downtime and high production efficiency. Strong commitment to quality control and safety, ensuring the production of high-quality ground components. Seeking a challenging role where I can leverage my expertise to contribute to the success of a dynamic organization.

Education

Associate’s Degree in Manufacturing Technology

January 2019

Skills

- CNC Grinding

- Surface Grinding

- Cylindrical Grinding

- Centerless Grinding

- Internal Grinding

- Thread Grinding

Work Experience

Grinding Wheel Operator

- Optimized grinding operations by implementing lean manufacturing techniques and reducing cycle times.

- Troubleshooted and resolved complex grinding issues, minimizing downtime and ensuring production efficiency.

- Developed and implemented quality control procedures to ensure the production of highquality ground components.

- Operated and maintained multiple grinding machines simultaneously, demonstrating multitasking abilities and efficiency.

Grinding Wheel Operator

- Utilized CNC control systems to program and operate grinding machines with precision and efficiency.

- Monitored and adjusted process parameters to achieve optimal surface finishes and dimensional accuracy.

- Inspected and maintained grinding wheels, ensuring they met industry standards and safety regulations.

- Collaborated with engineers and production teams to develop grinding processes and improve productivity.

Accomplishments

- Successfully implemented a new grinding technique that reduced material waste by 15%, resulting in significant cost savings.

- Collaborated with engineers to optimize grinding parameters, resulting in a 10% increase in grinding efficiency and improved product quality.

- Developed and implemented a training program for new grinding operators, effectively transferring knowledge and skills.

- Successfully troubleshooted and resolved complex grinding issues, ensuring uninterrupted production and minimizing downtime.

- Proactively identified and implemented maintenance procedures that extended the life of grinding machinery by 12%.

Awards

- Received Grinder of the Year award for achieving exceptional grinding precision and productivity on a regular basis.

- Honored with Safety Champion award for maintaining an impeccable safety record and promoting best practices in the grinding workshop.

- Recognized for exceptional attention to detail and dedication to quality, consistently achieving Zero Grind Errors status.

- Presented with Process Improvement Award for devising an innovative method to reduce grinding time by 5%.

Certificates

- Certified Grinding Wheel Operator (CGWO)

- Certified Surface Grinding Operator (CSGO)

- Certified Cylindrical Grinding Operator (CCGO)

- Certified Centerless Grinding Operator (CCLO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Grinding Wheel Operator

- Highlight your expertise in CNC grinding and various grinding techniques.

- Quantify your accomplishments with specific metrics, such as improved surface finishes, reduced cycle times, or increased production efficiency.

- Emphasize your ability to troubleshoot and resolve complex grinding issues.

- Showcase your commitment to quality control and safety by mentioning any relevant certifications or experience.

- Tailor your resume to each specific job description, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Grinding Wheel Operator Resume

- Programmed and operated CNC grinding machines to achieve desired surface finishes and dimensional accuracy.

- Monitored and adjusted process parameters, including wheel speed, feed rate, and coolant flow, to optimize grinding operations.

- Inspected and maintained grinding wheels, ensuring they met industry standards and safety regulations.

- Collaborated with engineers and production teams to develop grinding processes and improve productivity.

- Optimized grinding operations by implementing lean manufacturing techniques and reducing cycle times.

- Troubleshooted and resolved complex grinding issues, minimizing downtime and ensuring production efficiency.

- Developed and implemented quality control procedures to ensure the production of high-quality ground components.

Frequently Asked Questions (FAQ’s) For Grinding Wheel Operator

What are the key skills required to be a successful Grinding Wheel Operator?

The key skills required for a successful Grinding Wheel Operator include a strong understanding of CNC grinding machines, grinding processes, and quality control procedures. Proficiency in various grinding techniques, such as surface grinding, cylindrical grinding, and internal grinding, is also essential. Additionally, excellent troubleshooting and problem-solving skills are crucial to ensure minimal downtime and high production efficiency.

What are the career prospects for a Grinding Wheel Operator?

Grinding Wheel Operators with the right skills and experience can advance to supervisory roles, such as Lead Operator or Supervisor. With additional training and education, they may also qualify for positions in quality control, engineering, or management.

What are the safety precautions that Grinding Wheel Operators must follow?

Grinding Wheel Operators must follow strict safety precautions to minimize the risk of accidents. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They must also be trained in the proper handling and storage of grinding wheels and other hazardous materials.

What are the different types of grinding machines that a Grinding Wheel Operator may operate?

Grinding Wheel Operators may operate various types of grinding machines, including CNC grinding machines, surface grinders, cylindrical grinders, centerless grinders, internal grinders, and thread grinders. Each type of machine is designed for specific grinding tasks and requires specialized knowledge and skills to operate.

What are the quality control procedures that a Grinding Wheel Operator must follow?

Grinding Wheel Operators must follow established quality control procedures to ensure the production of high-quality ground components. This includes inspecting raw materials, finished products, and grinding wheels regularly. They must also maintain detailed records of grinding parameters and process adjustments.