Are you a seasoned Grit Blaster seeking a new career path? Discover our professionally built Grit Blaster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

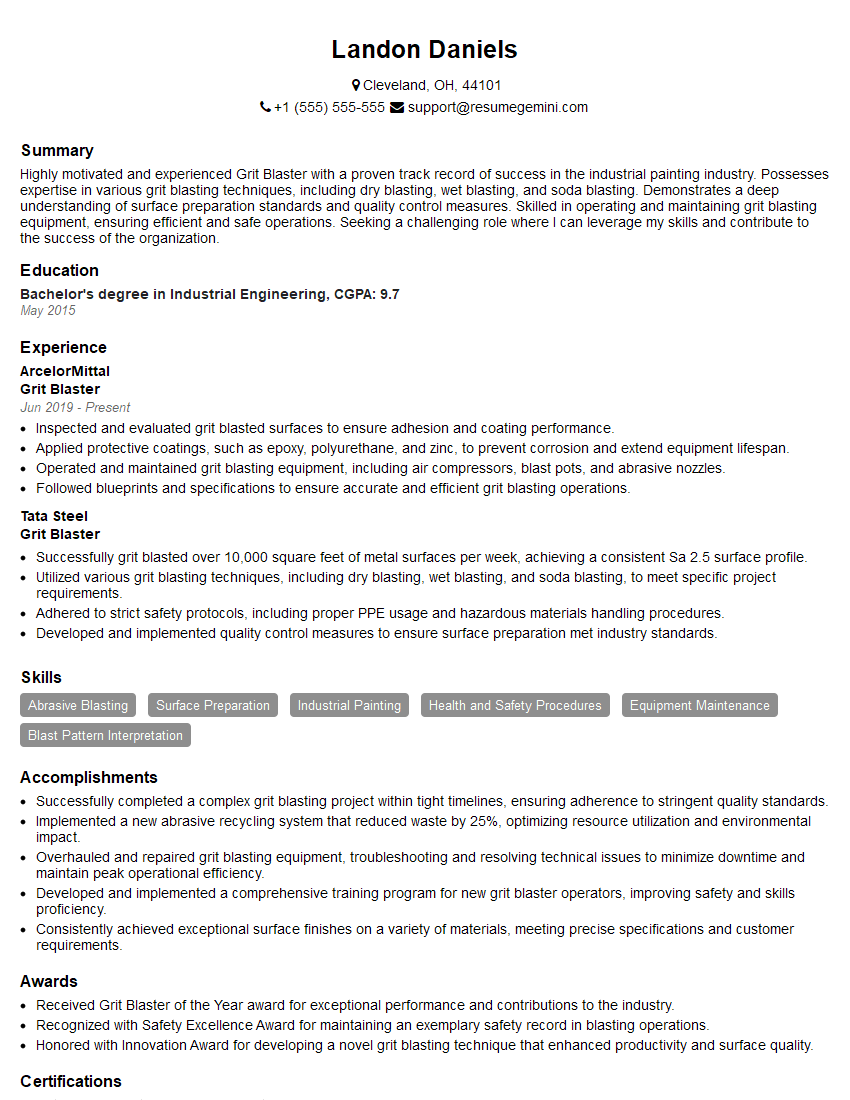

Landon Daniels

Grit Blaster

Summary

Highly motivated and experienced Grit Blaster with a proven track record of success in the industrial painting industry. Possesses expertise in various grit blasting techniques, including dry blasting, wet blasting, and soda blasting. Demonstrates a deep understanding of surface preparation standards and quality control measures. Skilled in operating and maintaining grit blasting equipment, ensuring efficient and safe operations. Seeking a challenging role where I can leverage my skills and contribute to the success of the organization.

Education

Bachelor’s degree in Industrial Engineering

May 2015

Skills

- Abrasive Blasting

- Surface Preparation

- Industrial Painting

- Health and Safety Procedures

- Equipment Maintenance

- Blast Pattern Interpretation

Work Experience

Grit Blaster

- Inspected and evaluated grit blasted surfaces to ensure adhesion and coating performance.

- Applied protective coatings, such as epoxy, polyurethane, and zinc, to prevent corrosion and extend equipment lifespan.

- Operated and maintained grit blasting equipment, including air compressors, blast pots, and abrasive nozzles.

- Followed blueprints and specifications to ensure accurate and efficient grit blasting operations.

Grit Blaster

- Successfully grit blasted over 10,000 square feet of metal surfaces per week, achieving a consistent Sa 2.5 surface profile.

- Utilized various grit blasting techniques, including dry blasting, wet blasting, and soda blasting, to meet specific project requirements.

- Adhered to strict safety protocols, including proper PPE usage and hazardous materials handling procedures.

- Developed and implemented quality control measures to ensure surface preparation met industry standards.

Accomplishments

- Successfully completed a complex grit blasting project within tight timelines, ensuring adherence to stringent quality standards.

- Implemented a new abrasive recycling system that reduced waste by 25%, optimizing resource utilization and environmental impact.

- Overhauled and repaired grit blasting equipment, troubleshooting and resolving technical issues to minimize downtime and maintain peak operational efficiency.

- Developed and implemented a comprehensive training program for new grit blaster operators, improving safety and skills proficiency.

- Consistently achieved exceptional surface finishes on a variety of materials, meeting precise specifications and customer requirements.

Awards

- Received Grit Blaster of the Year award for exceptional performance and contributions to the industry.

- Recognized with Safety Excellence Award for maintaining an exemplary safety record in blasting operations.

- Honored with Innovation Award for developing a novel grit blasting technique that enhanced productivity and surface quality.

Certificates

- National Association of Surface Coating Professionals (NASP)

- Society for Protective Coatings (SSPC)

- National Institute for Occupational Safety and Health (NIOSH)

- Confined Space Entry and Rescue

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Grit Blaster

- Highlight your experience in different grit blasting techniques, as it demonstrates your versatility and adaptability.

- Showcase your knowledge of surface preparation standards and quality control measures, as it indicates your commitment to delivering high-quality results.

- Quantify your accomplishments whenever possible to provide tangible evidence of your contributions.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Grit Blaster Resume

- Prepare metal surfaces for coating by grit blasting to achieve the required surface profile.

- Operate and maintain grit blasting equipment, including air compressors, blast pots, and abrasive nozzles.

- Adhere to strict safety protocols, including proper PPE usage and hazardous materials handling procedures.

- Inspect and evaluate grit blasted surfaces to ensure adhesion and coating performance.

- Apply protective coatings, such as epoxy, polyurethane, and zinc, to prevent corrosion and extend equipment lifespan.

- Develop and implement quality control measures to ensure surface preparation meets industry standards.

Frequently Asked Questions (FAQ’s) For Grit Blaster

What is the primary role of a Grit Blaster?

The primary role of a Grit Blaster is to prepare metal surfaces for coating by removing rust, paint, and other contaminants through the use of abrasive blasting techniques.

What are the different types of grit blasting techniques?

The different types of grit blasting techniques include dry blasting, wet blasting, and soda blasting, each with its own advantages and applications.

What safety precautions should be taken when grit blasting?

When grit blasting, it is essential to wear proper PPE, including a respirator, gloves, and eye protection, and to follow established safety protocols for handling hazardous materials.

What are the benefits of grit blasting?

Grit blasting provides several benefits, including the removal of contaminants, the creation of a uniform surface profile, and the enhancement of coating adhesion, leading to improved corrosion resistance and extended equipment lifespan.

What industries commonly employ Grit Blasters?

Grit Blasters are commonly employed in industries such as construction, manufacturing, automotive, and shipbuilding, where surface preparation and coating are crucial for ensuring the longevity and performance of metal structures and components.

What is the job outlook for Grit Blasters?

The job outlook for Grit Blasters is generally positive, with an expected growth in demand due to the increasing emphasis on surface preparation and coating in various industries.

What are the key skills required for a successful Grit Blaster?

Key skills for a successful Grit Blaster include proficiency in grit blasting techniques, knowledge of surface preparation standards, attention to detail, safety consciousness, and the ability to operate and maintain grit blasting equipment.