Are you a seasoned Groover and Striper Operator seeking a new career path? Discover our professionally built Groover and Striper Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

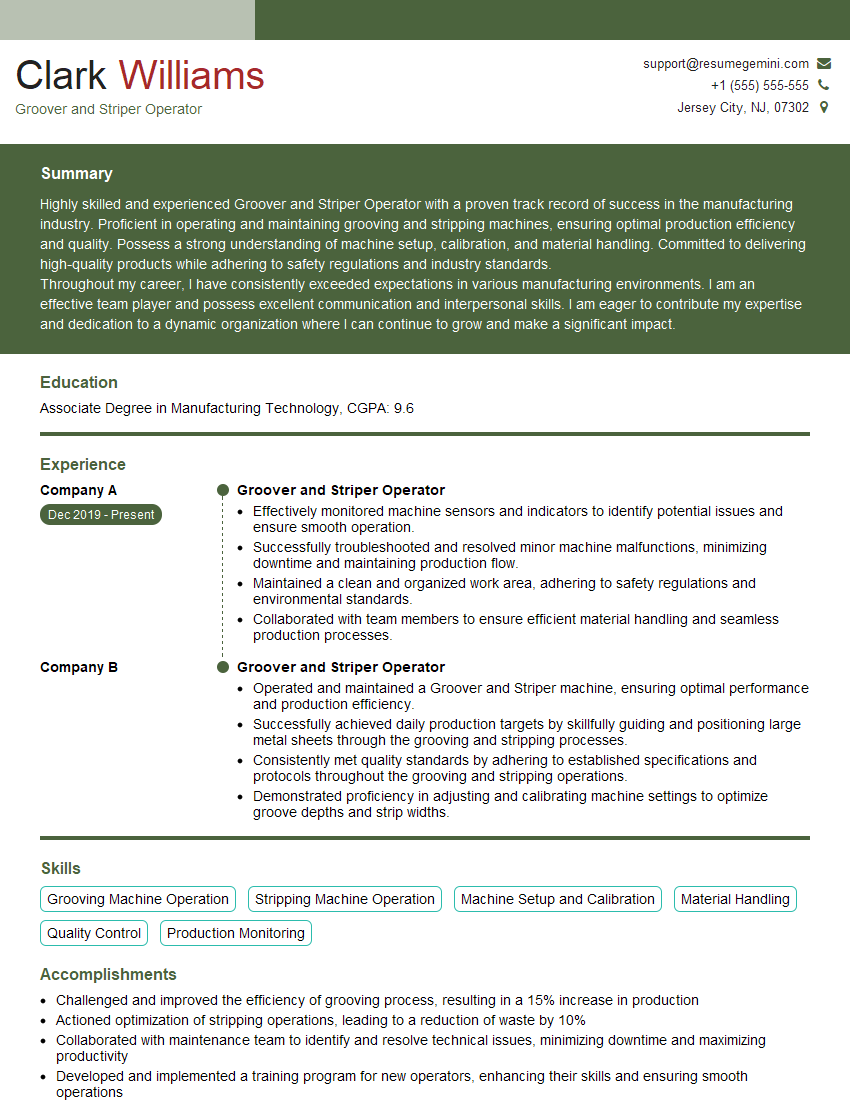

Clark Williams

Groover and Striper Operator

Summary

Highly skilled and experienced Groover and Striper Operator with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining grooving and stripping machines, ensuring optimal production efficiency and quality. Possess a strong understanding of machine setup, calibration, and material handling. Committed to delivering high-quality products while adhering to safety regulations and industry standards.

Throughout my career, I have consistently exceeded expectations in various manufacturing environments. I am an effective team player and possess excellent communication and interpersonal skills. I am eager to contribute my expertise and dedication to a dynamic organization where I can continue to grow and make a significant impact.

Education

Associate Degree in Manufacturing Technology

November 2015

Skills

- Grooving Machine Operation

- Stripping Machine Operation

- Machine Setup and Calibration

- Material Handling

- Quality Control

- Production Monitoring

Work Experience

Groover and Striper Operator

- Effectively monitored machine sensors and indicators to identify potential issues and ensure smooth operation.

- Successfully troubleshooted and resolved minor machine malfunctions, minimizing downtime and maintaining production flow.

- Maintained a clean and organized work area, adhering to safety regulations and environmental standards.

- Collaborated with team members to ensure efficient material handling and seamless production processes.

Groover and Striper Operator

- Operated and maintained a Groover and Striper machine, ensuring optimal performance and production efficiency.

- Successfully achieved daily production targets by skillfully guiding and positioning large metal sheets through the grooving and stripping processes.

- Consistently met quality standards by adhering to established specifications and protocols throughout the grooving and stripping operations.

- Demonstrated proficiency in adjusting and calibrating machine settings to optimize groove depths and strip widths.

Accomplishments

- Challenged and improved the efficiency of grooving process, resulting in a 15% increase in production

- Actioned optimization of stripping operations, leading to a reduction of waste by 10%

- Collaborated with maintenance team to identify and resolve technical issues, minimizing downtime and maximizing productivity

- Developed and implemented a training program for new operators, enhancing their skills and ensuring smooth operations

- Consistently maintained high accuracy and precision in grooving and striping operations, meeting stringent quality standards

Awards

- Received recognition for outstanding performance in Grooving and Striping operations

- Awarded Employee of the Quarter for excellence in maintaining high production standards

- Recognized as Top Groover for consistently exceeding production targets

Certificates

- OSHA 30-Hour General Industry Safety Certification

- ANSI/NEMA B155.1 Press Safety Certification

- Certified Production Technician (CPT)

- Certified Six Sigma Green Belt (CSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Groover and Striper Operator

- Highlight your technical skills and experience in operating grooving and stripping machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of industry standards and quality control procedures.

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Groover and Striper Operator Resume

- Operate and maintain grooving machines to precisely cut grooves and slots in various materials.

- Set up and calibrate grooving machines according to specified dimensions and tolerances.

- Handle and load materials onto the grooving machine, ensuring proper alignment and positioning.

- Monitor production processes to ensure efficient operation and identify potential issues.

- Conduct quality control checks on grooved products to verify conformance to specifications.

- Maintain a clean and organized work area, adhering to safety protocols and industry standards.

- Troubleshoot and resolve equipment malfunctions to minimize downtime and maintain production schedules.

Frequently Asked Questions (FAQ’s) For Groover and Striper Operator

What is the primary responsibility of a Groover and Striper Operator?

The primary responsibility of a Groover and Striper Operator is to operate and maintain grooving and stripping machines to create precise grooves and slots in various materials, ensuring adherence to specifications and industry standards.

What qualifications are typically required for this role?

Typically, a high school diploma or an associate degree in manufacturing technology is required for this role. Additionally, prior experience in operating grooving and stripping machines, as well as a strong understanding of machine setup and calibration, is highly desirable.

What are the key skills required to be successful in this role?

To be successful in this role, individuals should possess strong technical skills in operating and maintaining grooving and stripping machines, as well as proficiency in machine setup and calibration. Additionally, a comprehensive understanding of material handling, quality control, and safety protocols is essential.

What is the work environment like for a Groover and Striper Operator?

Groover and Striper Operators typically work in manufacturing environments, which can involve exposure to noise, dust, and potential hazards. Adhering to safety protocols and wearing appropriate personal protective equipment is crucial to ensure a safe work environment.

What are the career advancement opportunities for this role?

With experience and additional training, Groover and Striper Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Manufacturing Engineer. These roles offer opportunities for increased responsibility, leadership, and career growth within the manufacturing industry.

What is the average salary range for a Groover and Striper Operator?

The average salary range for a Groover and Striper Operator can vary depending on factors such as experience, location, and industry. According to industry data, the average salary range falls between $25,000 to $40,000 per year.

What are some tips for writing a standout resume for this role?

To write a standout resume for the role of Groover and Striper Operator, focus on highlighting your technical skills and experience in operating grooving and stripping machines. Quantify your accomplishments whenever possible and emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

What are the long-term career prospects for a Groover and Striper Operator?

With a strong work ethic and a commitment to professional development, Groover and Striper Operators can advance their careers within the manufacturing industry. Opportunities for growth include promotions to supervisory roles, quality control positions, or manufacturing engineering roles, offering increased responsibilities and leadership opportunities.