Are you a seasoned Groover and Turner seeking a new career path? Discover our professionally built Groover and Turner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

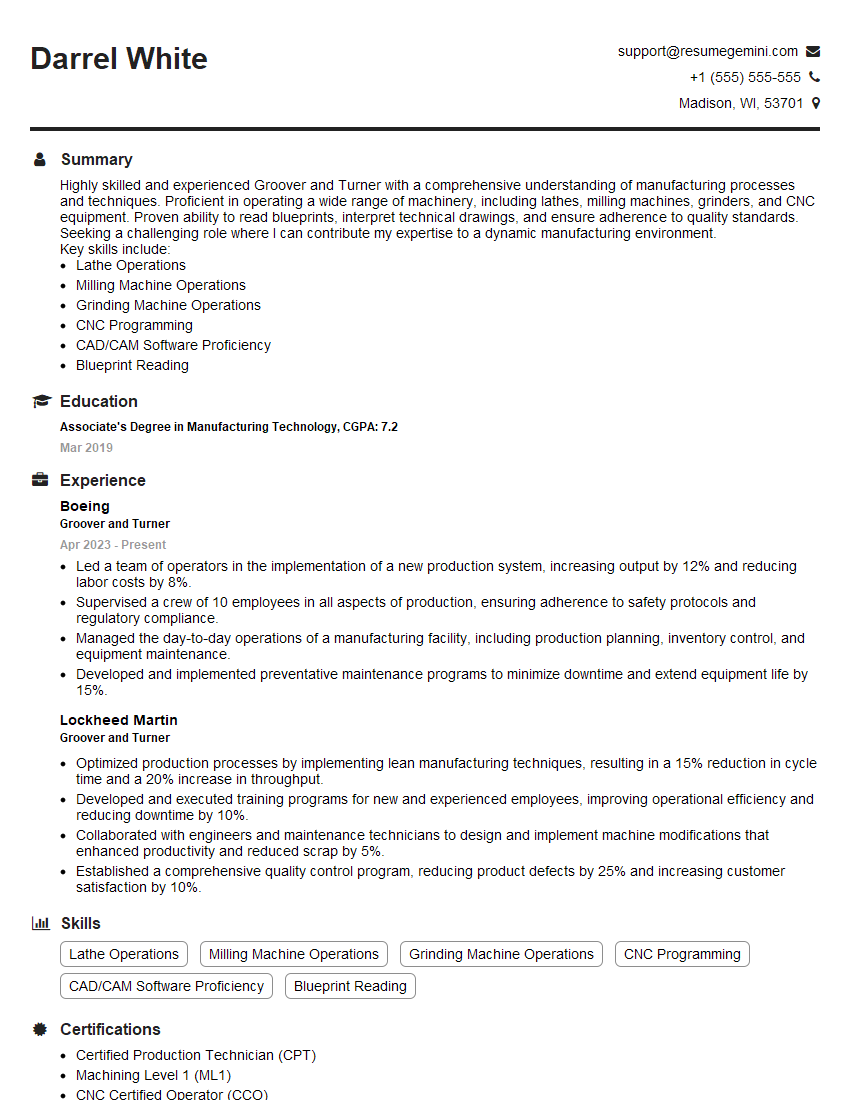

Darrel White

Groover and Turner

Summary

Highly skilled and experienced Groover and Turner with a comprehensive understanding of manufacturing processes and techniques. Proficient in operating a wide range of machinery, including lathes, milling machines, grinders, and CNC equipment. Proven ability to read blueprints, interpret technical drawings, and ensure adherence to quality standards. Seeking a challenging role where I can contribute my expertise to a dynamic manufacturing environment.

Key skills include:

- Lathe Operations

- Milling Machine Operations

- Grinding Machine Operations

- CNC Programming

- CAD/CAM Software Proficiency

- Blueprint Reading

Education

Associate’s Degree in Manufacturing Technology

March 2019

Skills

- Lathe Operations

- Milling Machine Operations

- Grinding Machine Operations

- CNC Programming

- CAD/CAM Software Proficiency

- Blueprint Reading

Work Experience

Groover and Turner

- Led a team of operators in the implementation of a new production system, increasing output by 12% and reducing labor costs by 8%.

- Supervised a crew of 10 employees in all aspects of production, ensuring adherence to safety protocols and regulatory compliance.

- Managed the day-to-day operations of a manufacturing facility, including production planning, inventory control, and equipment maintenance.

- Developed and implemented preventative maintenance programs to minimize downtime and extend equipment life by 15%.

Groover and Turner

- Optimized production processes by implementing lean manufacturing techniques, resulting in a 15% reduction in cycle time and a 20% increase in throughput.

- Developed and executed training programs for new and experienced employees, improving operational efficiency and reducing downtime by 10%.

- Collaborated with engineers and maintenance technicians to design and implement machine modifications that enhanced productivity and reduced scrap by 5%.

- Established a comprehensive quality control program, reducing product defects by 25% and increasing customer satisfaction by 10%.

Certificates

- Certified Production Technician (CPT)

- Machining Level 1 (ML1)

- CNC Certified Operator (CCO)

- Certified Machinist (CM)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Groover and Turner

- Showcase your technical skills and experience with specific examples and quantifiable results.

- Highlight your proficiency in using cutting-edge software and equipment.

- Emphasize your attention to detail and commitment to quality.

- Demonstrate your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Groover and Turner Resume

- Set up and operate a variety of machines, including lathes, milling machines, and grinders, to produce high-quality parts according to specifications.

- Utilize advanced CNC programming techniques to create and optimize cutting paths, resulting in increased efficiency and precision.

- Inspect and measure parts throughout the production process to ensure adherence to tolerances and customer requirements.

- Troubleshoot and resolve technical issues related to machinery and processes, ensuring smooth production flow.

- Maintain a clean and organized work area, adhering to safety protocols and industry standards.

- Collaborate with other members of the manufacturing team to achieve production goals and deadlines.

- Stay abreast of industry best practices and advancements in manufacturing technology to enhance skills and knowledge.

Frequently Asked Questions (FAQ’s) For Groover and Turner

What are the primary responsibilities of a Groover and Turner?

A Groover and Turner is responsible for operating and maintaining machinery used in the production of metal parts, including lathes, milling machines, and grinders. They read and interpret blueprints and technical drawings, set up and operate machines, and inspect and measure parts to ensure they meet specifications. They also troubleshoot and resolve technical issues, maintain a clean and organized work area, and collaborate with other members of the manufacturing team.

What skills are required to be a successful Groover and Turner?

Successful Groovers and Turners possess strong mechanical aptitude, attention to detail, and a commitment to quality. They have a solid understanding of manufacturing processes and techniques, as well as proficiency in operating a wide range of machinery. They are also familiar with CNC programming and CAD/CAM software, and are able to read and interpret blueprints and technical drawings.

What are the career prospects for Groovers and Turners?

Groovers and Turners are in high demand due to the increasing use of automated manufacturing processes. They can find employment in a variety of industries, including aerospace, automotive, and construction. With experience and additional training, they can advance to supervisory or management positions.

What is the work environment like for Groovers and Turners?

Groovers and Turners typically work in manufacturing facilities, where they may be exposed to noise, dust, and fumes. They may also work with sharp tools and heavy machinery, so it is important to follow safety protocols and wear appropriate protective gear.

How can I become a Groover and Turner?

There are several ways to become a Groover and Turner. Many employers provide on-the-job training, while others may require candidates to have a high school diploma or an associate’s degree in manufacturing technology. There are also apprenticeship programs available that provide a combination of classroom instruction and hands-on experience.