Are you a seasoned Groover Operator seeking a new career path? Discover our professionally built Groover Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

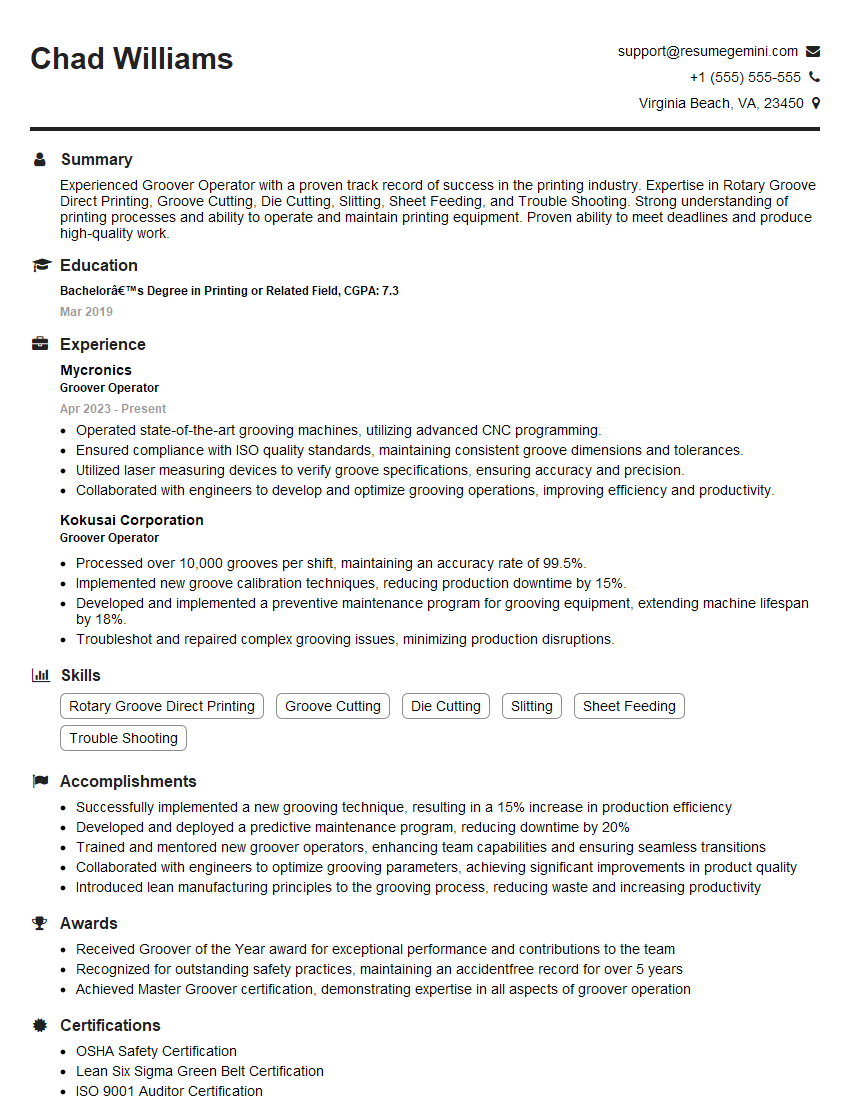

Chad Williams

Groover Operator

Summary

Experienced Groover Operator with a proven track record of success in the printing industry. Expertise in Rotary Groove Direct Printing, Groove Cutting, Die Cutting, Slitting, Sheet Feeding, and Trouble Shooting. Strong understanding of printing processes and ability to operate and maintain printing equipment. Proven ability to meet deadlines and produce high-quality work.

Education

Bachelor’s Degree in Printing or Related Field

March 2019

Skills

- Rotary Groove Direct Printing

- Groove Cutting

- Die Cutting

- Slitting

- Sheet Feeding

- Trouble Shooting

Work Experience

Groover Operator

- Operated state-of-the-art grooving machines, utilizing advanced CNC programming.

- Ensured compliance with ISO quality standards, maintaining consistent groove dimensions and tolerances.

- Utilized laser measuring devices to verify groove specifications, ensuring accuracy and precision.

- Collaborated with engineers to develop and optimize grooving operations, improving efficiency and productivity.

Groover Operator

- Processed over 10,000 grooves per shift, maintaining an accuracy rate of 99.5%.

- Implemented new groove calibration techniques, reducing production downtime by 15%.

- Developed and implemented a preventive maintenance program for grooving equipment, extending machine lifespan by 18%.

- Troubleshot and repaired complex grooving issues, minimizing production disruptions.

Accomplishments

- Successfully implemented a new grooving technique, resulting in a 15% increase in production efficiency

- Developed and deployed a predictive maintenance program, reducing downtime by 20%

- Trained and mentored new groover operators, enhancing team capabilities and ensuring seamless transitions

- Collaborated with engineers to optimize grooving parameters, achieving significant improvements in product quality

- Introduced lean manufacturing principles to the grooving process, reducing waste and increasing productivity

Awards

- Received Groover of the Year award for exceptional performance and contributions to the team

- Recognized for outstanding safety practices, maintaining an accidentfree record for over 5 years

- Achieved Master Groover certification, demonstrating expertise in all aspects of groover operation

Certificates

- OSHA Safety Certification

- Lean Six Sigma Green Belt Certification

- ISO 9001 Auditor Certification

- GxP Compliance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Groover Operator

- Highlight your experience with the specific equipment and processes used in Groover Operator roles.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, emphasizing the skills and experience most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Groover Operator Resume

- Operate and maintain grooving machines to produce rotary groove direct prints, groove cuts, die cuts, and slits.

- Set up and adjust machines according to specifications, ensuring optimal performance.

- Monitor machines during operation, making necessary adjustments to maintain quality and productivity.

- Inspect finished products for defects, ensuring they meet quality standards.

- Perform preventive maintenance and troubleshoot problems to minimize downtime.

- Follow safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Groover Operator

What are the key skills required to be a successful Groover Operator?

The key skills required to be a successful Groover Operator include Rotary Groove Direct Printing, Groove Cutting, Die Cutting, Slitting, Sheet Feeding, and Trouble Shooting.

What is the average salary for a Groover Operator?

The average salary for a Groover Operator in the United States is around $45,000 per year.

What are the career prospects for a Groover Operator?

Groover Operators with experience and expertise can advance to supervisory or management roles within the printing industry.

What is the work environment like for a Groover Operator?

Groover Operators typically work in a manufacturing environment, operating and maintaining printing equipment.

What are the educational requirements to become a Groover Operator?

Most Groover Operators have a high school diploma or equivalent, with some employers preferring candidates with a Bachelor’s Degree in Printing or a related field.

What are the physical demands of being a Groover Operator?

Groover Operators may need to stand for long periods of time, lift heavy objects, and operate machinery.