Are you a seasoned Guide Winder seeking a new career path? Discover our professionally built Guide Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

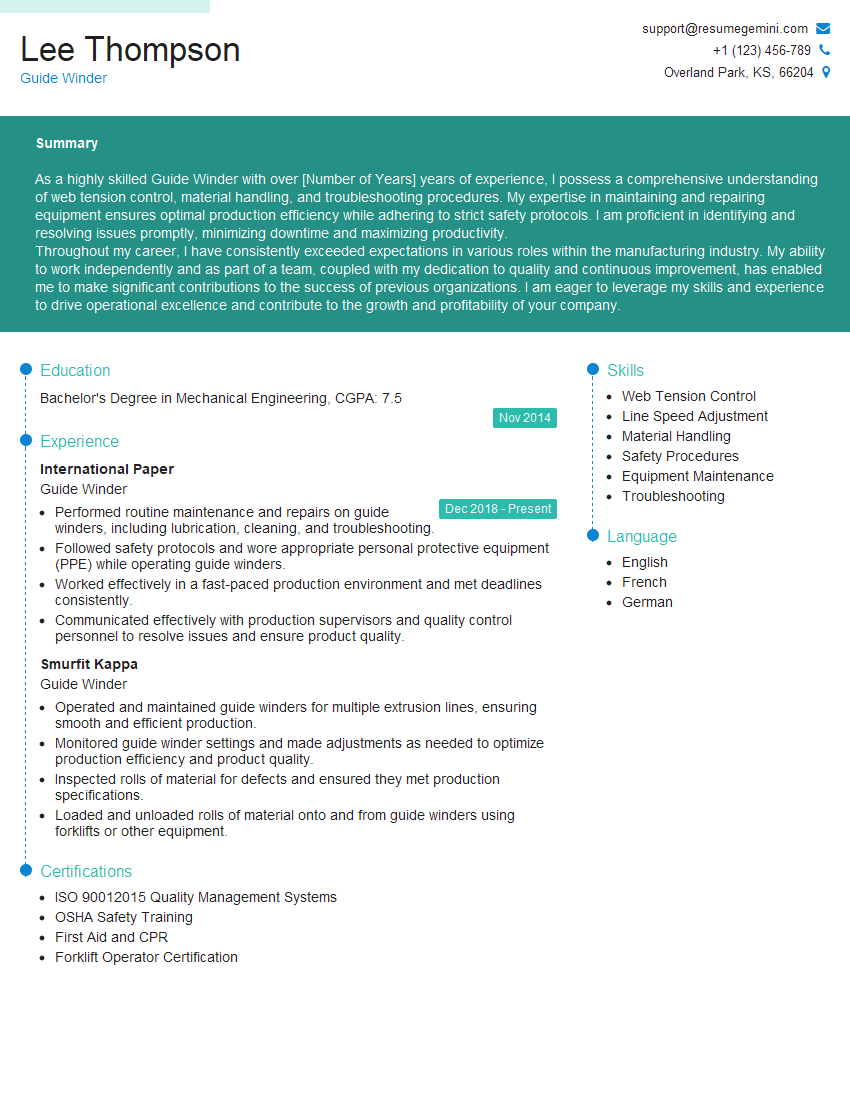

Lee Thompson

Guide Winder

Summary

Summary

As a highly skilled Guide Winder with over [Number of Years] years of experience, I possess a comprehensive understanding of web tension control, material handling, and troubleshooting procedures. My expertise in maintaining and repairing equipment ensures optimal production efficiency while adhering to strict safety protocols. I am proficient in identifying and resolving issues promptly, minimizing downtime and maximizing productivity.

Throughout my career, I have consistently exceeded expectations in various roles within the manufacturing industry. My ability to work independently and as part of a team, coupled with my dedication to quality and continuous improvement, has enabled me to make significant contributions to the success of previous organizations. I am eager to leverage my skills and experience to drive operational excellence and contribute to the growth and profitability of your company.

Education

Bachelor’s Degree in Mechanical Engineering

November 2014

Skills

- Web Tension Control

- Line Speed Adjustment

- Material Handling

- Safety Procedures

- Equipment Maintenance

- Troubleshooting

Work Experience

Guide Winder

- Performed routine maintenance and repairs on guide winders, including lubrication, cleaning, and troubleshooting.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) while operating guide winders.

- Worked effectively in a fast-paced production environment and met deadlines consistently.

- Communicated effectively with production supervisors and quality control personnel to resolve issues and ensure product quality.

Guide Winder

- Operated and maintained guide winders for multiple extrusion lines, ensuring smooth and efficient production.

- Monitored guide winder settings and made adjustments as needed to optimize production efficiency and product quality.

- Inspected rolls of material for defects and ensured they met production specifications.

- Loaded and unloaded rolls of material onto and from guide winders using forklifts or other equipment.

Certificates

- ISO 90012015 Quality Management Systems

- OSHA Safety Training

- First Aid and CPR

- Forklift Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Guide Winder

- Highlight your technical skills: Emphasize your expertise in web tension control, line speed adjustment, material handling, and equipment maintenance.

- Quantify your accomplishments: Use specific metrics and examples to demonstrate the positive impact of your work on production efficiency and quality.

- Showcase your problem-solving abilities: Describe instances where you identified and resolved complex issues, highlighting your analytical and troubleshooting skills.

- Emphasize your safety??: State your commitment to adhering to safety procedures and minimizing risks in the workplace.

- Proofread carefully: Ensure that your resume is error-free and well-organized, as attention to detail is crucial for a Guide Winder.

Essential Experience Highlights for a Strong Guide Winder Resume

- Control web tension to ensure proper winding and prevent material damage.

- Adjust line speed to maintain optimal production rates while minimizing waste.

- Handle and load various materials, including paper, plastic, and metal, ensuring their proper positioning and alignment.

- Conduct regular inspections and maintenance on equipment to prevent breakdowns and ensure optimal performance.

- Troubleshoot and resolve issues related to equipment operation, material handling, and web tension.

- Adhere to established safety procedures and protocols to minimize risks and maintain a safe work environment.

- Work closely with other team members, including operators, supervisors, and engineers, to achieve production goals and improve processes.

Frequently Asked Questions (FAQ’s) For Guide Winder

What is the primary role of a Guide Winder?

A Guide Winder is responsible for controlling web tension, adjusting line speed, handling materials, maintaining equipment, and troubleshooting issues related to the winding process to ensure smooth and efficient production.

What are the essential skills required for a Guide Winder?

Essential skills for a Guide Winder include web tension control, line speed adjustment, material handling, safety procedures, equipment maintenance, and troubleshooting.

What industries commonly employ Guide Winders?

Guide Winders are employed in various industries that utilize roll-to-roll processes, such as paper manufacturing, plastic film production, and metal processing.

What are the career advancement opportunities for a Guide Winder?

With experience and additional training, Guide Winders can advance to supervisory roles, such as Production Supervisor or Maintenance Manager, or specialize in areas like equipment maintenance or process optimization.

What is the average salary range for a Guide Winder?

The average salary range for a Guide Winder varies depending on factors such as experience, location, and industry. However, according to Indeed, the average salary for a Guide Winder in the United States is approximately [Salary Range].

What are the key qualities of a successful Guide Winder?

Successful Guide Winders possess strong attention to detail, problem-solving abilities, mechanical aptitude, and a commitment to safety. They are also typically physically fit and able to work in a fast-paced environment.

What are the common challenges faced by Guide Winders?

Common challenges faced by Guide Winders include maintaining consistent web tension, minimizing material waste, resolving equipment malfunctions, and ensuring adherence to safety regulations.

What are the latest trends and technologies impacting the role of Guide Winders?

Emerging trends and technologies, such as automation, data analytics, and predictive maintenance, are influencing the role of Guide Winders, allowing for increased efficiency, reduced downtime, and improved quality control.