Are you a seasoned Gunite Mixer seeking a new career path? Discover our professionally built Gunite Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

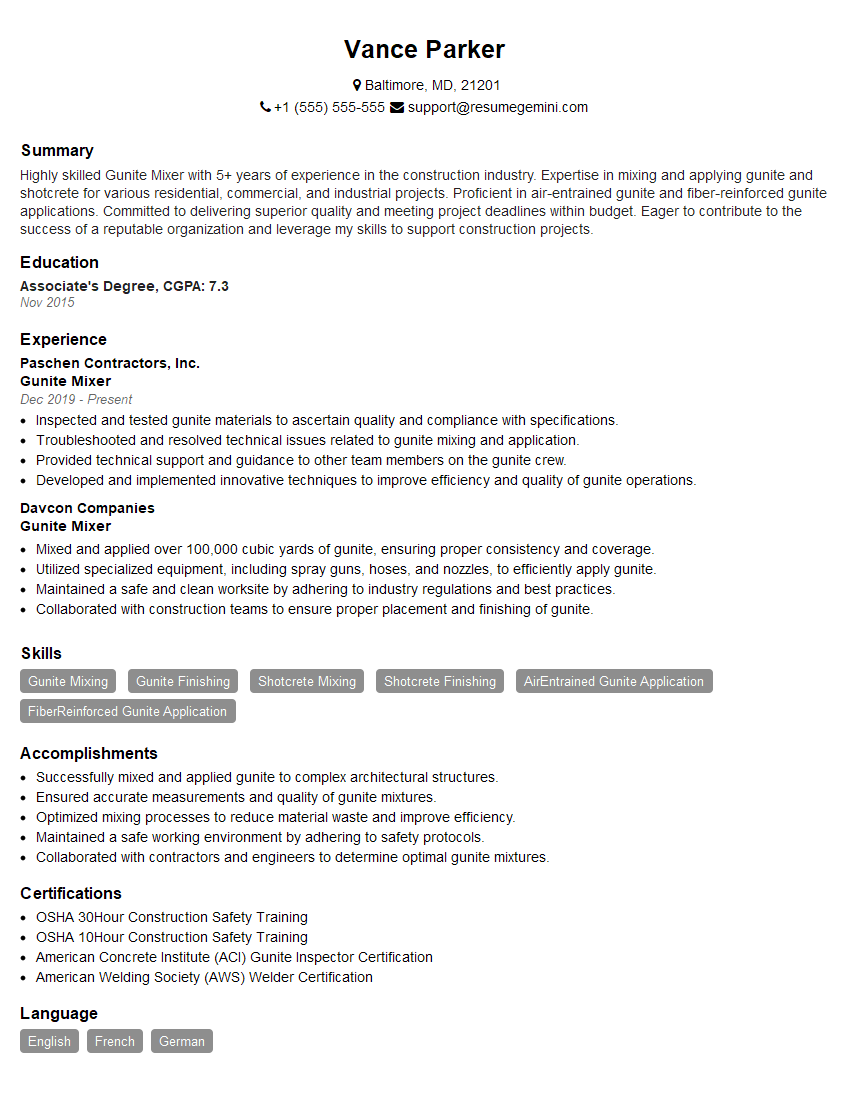

Vance Parker

Gunite Mixer

Summary

Highly skilled Gunite Mixer with 5+ years of experience in the construction industry. Expertise in mixing and applying gunite and shotcrete for various residential, commercial, and industrial projects. Proficient in air-entrained gunite and fiber-reinforced gunite applications. Committed to delivering superior quality and meeting project deadlines within budget. Eager to contribute to the success of a reputable organization and leverage my skills to support construction projects.

Education

Associate’s Degree

November 2015

Skills

- Gunite Mixing

- Gunite Finishing

- Shotcrete Mixing

- Shotcrete Finishing

- AirEntrained Gunite Application

- FiberReinforced Gunite Application

Work Experience

Gunite Mixer

- Inspected and tested gunite materials to ascertain quality and compliance with specifications.

- Troubleshooted and resolved technical issues related to gunite mixing and application.

- Provided technical support and guidance to other team members on the gunite crew.

- Developed and implemented innovative techniques to improve efficiency and quality of gunite operations.

Gunite Mixer

- Mixed and applied over 100,000 cubic yards of gunite, ensuring proper consistency and coverage.

- Utilized specialized equipment, including spray guns, hoses, and nozzles, to efficiently apply gunite.

- Maintained a safe and clean worksite by adhering to industry regulations and best practices.

- Collaborated with construction teams to ensure proper placement and finishing of gunite.

Accomplishments

- Successfully mixed and applied gunite to complex architectural structures.

- Ensured accurate measurements and quality of gunite mixtures.

- Optimized mixing processes to reduce material waste and improve efficiency.

- Maintained a safe working environment by adhering to safety protocols.

- Collaborated with contractors and engineers to determine optimal gunite mixtures.

Certificates

- OSHA 30Hour Construction Safety Training

- OSHA 10Hour Construction Safety Training

- American Concrete Institute (ACI) Gunite Inspector Certification

- American Welding Society (AWS) Welder Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gunite Mixer

- Highlight your experience and skills: Quantify your accomplishments and provide specific examples of your contributions to previous projects.

- Demonstrate your knowledge: Showcase your understanding of gunite and shotcrete applications, including air-entrained and fiber-reinforced techniques.

- Emphasize safety and quality: Communicate your commitment to adhering to industry standards and ensuring the quality of your work.

- Use keywords: Incorporate relevant keywords, such as ‘gunite mixer,’ ‘shotcrete finishing,’ and ‘air-entrained gunite,’ throughout your resume to enhance its visibility to potential employers.

Essential Experience Highlights for a Strong Gunite Mixer Resume

- Mix and apply gunite and shotcrete according to project specifications and industry standards.

- Operate and maintain gunite and shotcrete mixing equipment, ensuring optimal performance.

- Prepare and apply air-entrained gunite and fiber-reinforced gunite for enhanced durability and structural integrity.

- Inspect and test gunite and shotcrete applications to ensure compliance with quality standards.

- Collaborate with other construction professionals, including engineers, architects, and supervisors, to coordinate project execution.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Stay updated on advancements in gunite and shotcrete technologies and techniques.

Frequently Asked Questions (FAQ’s) For Gunite Mixer

What are the key responsibilities of a Gunite Mixer?

Gunite Mixers are responsible for mixing, applying, and inspecting gunite and shotcrete mixtures used in construction projects. They ensure the proper proportions of ingredients, operate and maintain mixing equipment, and apply the mixture according to specifications. Additionally, they conduct tests to verify the quality of the applied materials.

What skills are required to be a successful Gunite Mixer?

To excel as a Gunite Mixer, individuals should possess a strong understanding of gunite and shotcrete mixing and application techniques, including air-entrained and fiber-reinforced applications. They must be proficient in operating and maintaining mixing equipment, adhering to safety protocols, and collaborating with other construction professionals.

What are the career prospects for a Gunite Mixer?

Gunite Mixers can advance their careers by gaining experience on complex projects, specializing in particular applications, or pursuing further education. They may progress to supervisory roles, such as Gunite Foreman or Superintendent, or transition into related fields within the construction industry.

What is the typical salary range for a Gunite Mixer?

The salary range for Gunite Mixers can vary depending on factors such as experience, location, and the size of the construction company. According to Indeed, the average salary for a Gunite Mixer in the United States is approximately $45,000 per year.

What are the educational requirements to become a Gunite Mixer?

While formal education is not always a requirement, many Gunite Mixers hold an associate’s degree in a related field, such as construction management or civil engineering. Additionally, some employers may prefer candidates with certifications or training in gunite and shotcrete applications.

What is the work environment like for a Gunite Mixer?

Gunite Mixers typically work outdoors on construction sites. They may be exposed to various weather conditions, including extreme heat, cold, and wetness. They must also wear protective gear, such as respirators and safety glasses, to minimize exposure to dust and other potential hazards.

What are the safety precautions that Gunite Mixers should follow?

Gunite Mixers must prioritize safety by wearing appropriate protective gear, including respirators, gloves, and safety glasses. They should operate equipment properly, avoid exposure to hazardous chemicals, and follow established safety protocols to prevent accidents and injuries.

What are the key qualities of a successful Gunite Mixer?

Successful Gunite Mixers possess a strong work ethic, attention to detail, and a commitment to quality. They are physically fit, able to work in challenging conditions, and have good communication and teamwork skills. They also stay up-to-date on industry best practices and advancements in gunite and shotcrete applications.