Are you a seasoned Hand Coremaker seeking a new career path? Discover our professionally built Hand Coremaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

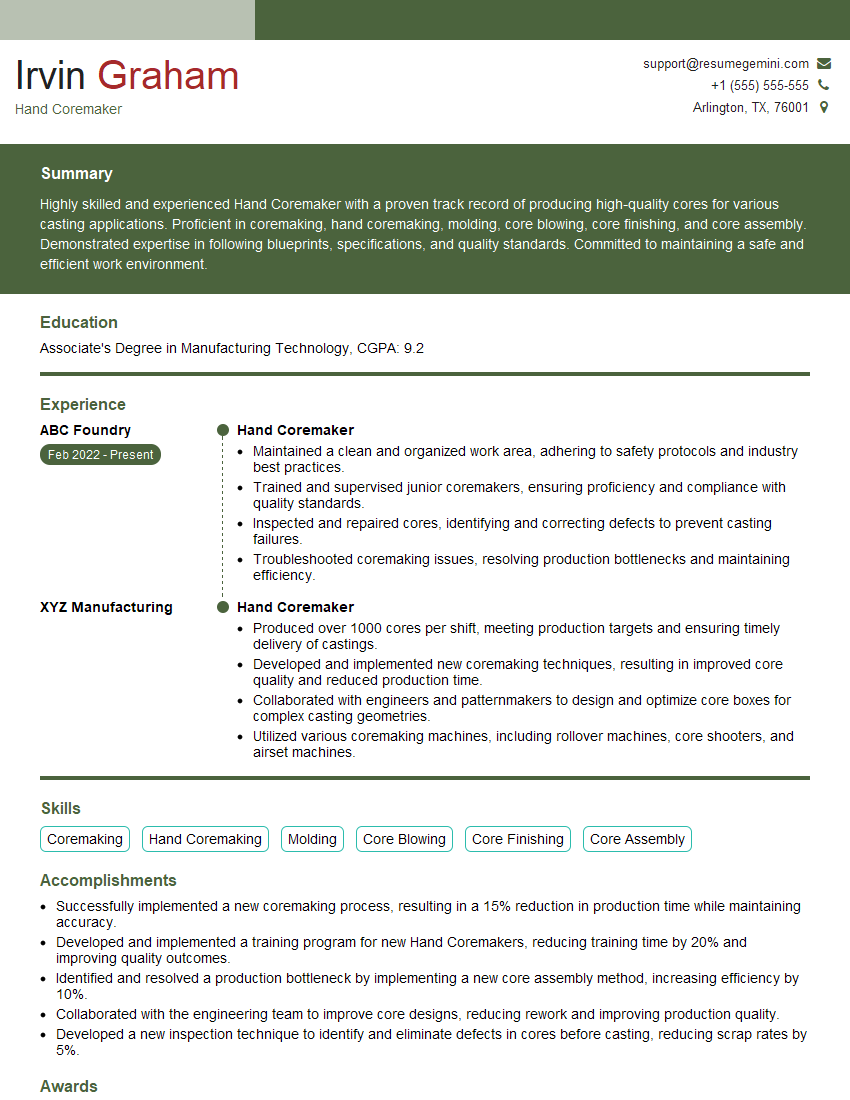

Irvin Graham

Hand Coremaker

Summary

Highly skilled and experienced Hand Coremaker with a proven track record of producing high-quality cores for various casting applications. Proficient in coremaking, hand coremaking, molding, core blowing, core finishing, and core assembly. Demonstrated expertise in following blueprints, specifications, and quality standards. Committed to maintaining a safe and efficient work environment.

Education

Associate’s Degree in Manufacturing Technology

January 2018

Skills

- Coremaking

- Hand Coremaking

- Molding

- Core Blowing

- Core Finishing

- Core Assembly

Work Experience

Hand Coremaker

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Trained and supervised junior coremakers, ensuring proficiency and compliance with quality standards.

- Inspected and repaired cores, identifying and correcting defects to prevent casting failures.

- Troubleshooted coremaking issues, resolving production bottlenecks and maintaining efficiency.

Hand Coremaker

- Produced over 1000 cores per shift, meeting production targets and ensuring timely delivery of castings.

- Developed and implemented new coremaking techniques, resulting in improved core quality and reduced production time.

- Collaborated with engineers and patternmakers to design and optimize core boxes for complex casting geometries.

- Utilized various coremaking machines, including rollover machines, core shooters, and airset machines.

Accomplishments

- Successfully implemented a new coremaking process, resulting in a 15% reduction in production time while maintaining accuracy.

- Developed and implemented a training program for new Hand Coremakers, reducing training time by 20% and improving quality outcomes.

- Identified and resolved a production bottleneck by implementing a new core assembly method, increasing efficiency by 10%.

- Collaborated with the engineering team to improve core designs, reducing rework and improving production quality.

- Developed a new inspection technique to identify and eliminate defects in cores before casting, reducing scrap rates by 5%.

Awards

- Recognized with the Employee Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Awarded the Hand Coremaker of the Year Award for outstanding performance, including exceeding production goals and achieving zero defects.

- Recognized with the Safety Excellence Award for maintaining a clean and hazardfree work area, contributing to a safe workplace.

- Awarded the Employee Suggestion Award for proposing a costsaving initiative that reduced material waste by 7%.

Certificates

- Coremaker Certification

- Hand Coremaker Certification

- OSHA Safety Certification

- ASME B5.42 Coremaking Standard

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hand Coremaker

- Quantify your accomplishments whenever possible, using specific metrics.

- Highlight your knowledge of coremaking materials and processes.

- Emphasize your attention to detail and commitment to quality.

- Seek opportunities to demonstrate your teamwork and problem-solving abilities.

Essential Experience Highlights for a Strong Hand Coremaker Resume

- Prepare and maintain core boxes, patterns, and other tools to ensure optimal core production.

- Mix and prepare core sand according to specifications, ensuring proper consistency and composition.

- Hand-craft cores using various techniques, such as ramming, jolting, or blowing, to meet design specifications.

- Perform core finishing operations, including trimming, patching, and coating, to ensure dimensional accuracy and surface quality.

- Assemble cores into complex casting components, adhering to established procedures and quality standards.

- Conduct routine inspections and monitor core production processes to identify and resolve any potential issues.

- Maintain a clean and organized work area, adhering to safety regulations and environmental best practices.

Frequently Asked Questions (FAQ’s) For Hand Coremaker

What are the primary duties of a Hand Coremaker?

Hand Coremakers are responsible for creating and assembling cores, which are essential components of metal castings. Their duties include preparing core boxes, mixing core sand, hand-crafting cores, performing core finishing operations, and assembling cores into complex casting components.

What skills are required to be a successful Hand Coremaker?

Successful Hand Coremakers possess proficiency in coremaking, hand coremaking, molding, core blowing, core finishing, and core assembly. They have a strong understanding of coremaking materials and processes, and are skilled in using various tools and equipment. Additionally, they demonstrate attention to detail, commitment to quality, and ability to work independently and as part of a team.

What are the career prospects for Hand Coremakers?

Hand Coremakers can advance their careers by developing specialized skills and knowledge in areas such as coremaking automation, quality control, or supervision. They may also pursue higher education to enhance their technical foundation and qualify for management or engineering roles within the foundry industry.

Is there a demand for Hand Coremakers in the job market?

Yes, there is a steady demand for skilled Hand Coremakers in the manufacturing sector. Foundries and other companies that produce metal castings rely on Hand Coremakers to create high-quality cores that are essential for the production of various metal products.

What is the average salary range for Hand Coremakers?

The salary range for Hand Coremakers can vary depending on factors such as experience, location, and industry. According to industry sources, the average salary for Hand Coremakers in the United States ranges from $35,000 to $55,000 per year.

What are the working conditions like for Hand Coremakers?

Hand Coremakers typically work in manufacturing facilities or foundries. The work can be physically demanding and may involve exposure to dust, noise, and fumes. However, employers are required to provide a safe and healthy work environment, and Hand Coremakers are equipped with appropriate protective gear.

How can I become a Hand Coremaker?

To become a Hand Coremaker, you can pursue an Associate’s Degree in Manufacturing Technology or a related field, or gain hands-on experience through an apprenticeship program. Additionally, obtaining industry-recognized certifications, such as those offered by the American Foundry Society, can enhance your credibility and job prospects.