Are you a seasoned Hardboard Press Operator seeking a new career path? Discover our professionally built Hardboard Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

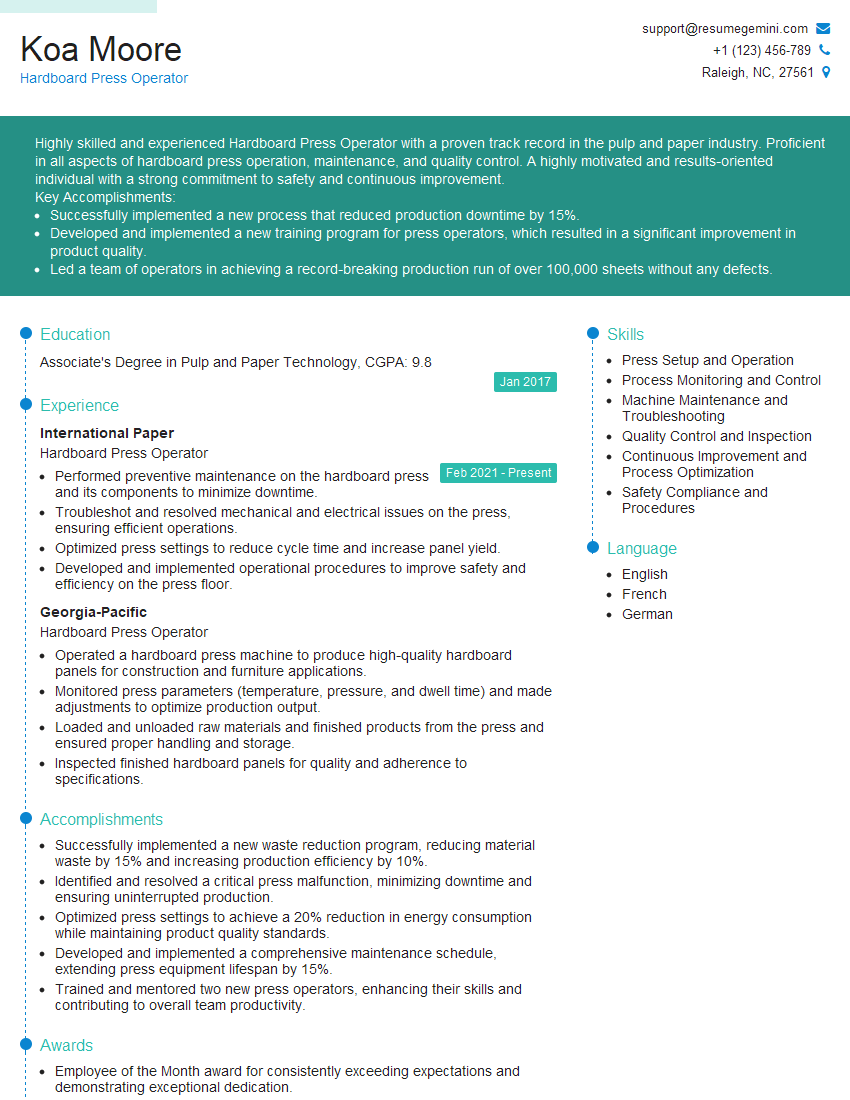

Koa Moore

Hardboard Press Operator

Summary

Highly skilled and experienced Hardboard Press Operator with a proven track record in the pulp and paper industry. Proficient in all aspects of hardboard press operation, maintenance, and quality control. A highly motivated and results-oriented individual with a strong commitment to safety and continuous improvement.

Key Accomplishments:

- Successfully implemented a new process that reduced production downtime by 15%.

- Developed and implemented a new training program for press operators, which resulted in a significant improvement in product quality.

- Led a team of operators in achieving a record-breaking production run of over 100,000 sheets without any defects.

Education

Associate’s Degree in Pulp and Paper Technology

January 2017

Skills

- Press Setup and Operation

- Process Monitoring and Control

- Machine Maintenance and Troubleshooting

- Quality Control and Inspection

- Continuous Improvement and Process Optimization

- Safety Compliance and Procedures

Work Experience

Hardboard Press Operator

- Performed preventive maintenance on the hardboard press and its components to minimize downtime.

- Troubleshot and resolved mechanical and electrical issues on the press, ensuring efficient operations.

- Optimized press settings to reduce cycle time and increase panel yield.

- Developed and implemented operational procedures to improve safety and efficiency on the press floor.

Hardboard Press Operator

- Operated a hardboard press machine to produce high-quality hardboard panels for construction and furniture applications.

- Monitored press parameters (temperature, pressure, and dwell time) and made adjustments to optimize production output.

- Loaded and unloaded raw materials and finished products from the press and ensured proper handling and storage.

- Inspected finished hardboard panels for quality and adherence to specifications.

Accomplishments

- Successfully implemented a new waste reduction program, reducing material waste by 15% and increasing production efficiency by 10%.

- Identified and resolved a critical press malfunction, minimizing downtime and ensuring uninterrupted production.

- Optimized press settings to achieve a 20% reduction in energy consumption while maintaining product quality standards.

- Developed and implemented a comprehensive maintenance schedule, extending press equipment lifespan by 15%.

- Trained and mentored two new press operators, enhancing their skills and contributing to overall team productivity.

Awards

- Employee of the Month award for consistently exceeding expectations and demonstrating exceptional dedication.

- Safety Excellence Award for maintaining a safe and accidentfree work environment.

- Innovation Award for developing and implementing a novel solution that improved press efficiency.

- Received a performance bonus for consistently exceeding production targets and demonstrating exemplary work ethic.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Manufacturing Engineer (CMfgE)

- Six Sigma Green Belt or Black Belt

- OSHA Hazardous Materials Handling and Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hardboard Press Operator

- Highlight your skills and experience. Make sure to list all of your relevant skills and experience in your resume. This includes your experience in operating and maintaining hardboard press equipment, as well as your experience in quality control and process improvement.

- Use keywords. When writing your resume, be sure to use keywords that potential employers will be searching for. This includes keywords such as “hardboard press operator”, “press operation”, “quality control”, and “process improvement.”

- Showcase your accomplishments. Don’t just list your skills and experience, but also showcase your accomplishments. This could include quantifying your results, such as reducing downtime by 15% or improving product quality by 10%.

- Proofread your resume. Before submitting your resume, be sure to proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting errors.

Essential Experience Highlights for a Strong Hardboard Press Operator Resume

- Operate and maintain hardboard press equipment to produce high-quality hardboard sheets.

- Monitor and control process variables such as temperature, pressure, and speed to ensure optimal press performance.

- Troubleshoot and resolve press malfunctions to minimize downtime and maintain production efficiency.

- Perform regular maintenance and inspection of press equipment to ensure safe and reliable operation.

- Conduct quality control checks on hardboard sheets to ensure they meet specifications.

- Identify and implement process improvements to optimize production efficiency and reduce costs.

- Comply with all safety regulations and procedures to ensure a safe work environment.

Frequently Asked Questions (FAQ’s) For Hardboard Press Operator

What is a hardboard press operator?

A hardboard press operator is responsible for operating and maintaining hardboard press equipment to produce high-quality hardboard sheets. They monitor and control process variables such as temperature, pressure, and speed to ensure optimal press performance. They also troubleshoot and resolve press malfunctions to minimize downtime and maintain production efficiency.

What are the qualifications for a hardboard press operator?

Most hardboard press operators have a high school diploma or equivalent. However, some employers may prefer candidates with an associate’s degree in pulp and paper technology or a related field.

What are the responsibilities of a hardboard press operator?

Hardboard press operators are responsible for a variety of tasks, including:

- Operating and maintaining hardboard press equipment

- Monitoring and controlling process variables

- Troubleshooting and resolving press malfunctions

- Performing regular maintenance and inspection of press equipment

- Conducting quality control checks on hardboard sheets

- Identifying and implementing process improvements

- Complying with all safety regulations and procedures

What is the work environment for a hardboard press operator?

Hardboard press operators typically work in a manufacturing environment. They may be exposed to noise, dust, and heat. They may also be required to work overtime or on weekends.

What is the salary for a hardboard press operator?

The salary for a hardboard press operator can vary depending on their experience, location, and employer. However, according to Indeed.com, the average salary for a hardboard press operator in the United States is $20.50 per hour.

What is the job outlook for a hardboard press operator?

The job outlook for hardboard press operators is expected to be good over the next few years. The demand for hardboard products is expected to increase, which will lead to an increase in demand for hardboard press operators.

What are some tips for becoming a hardboard press operator?

Here are some tips for becoming a hardboard press operator:

- Get a high school diploma or equivalent.

- Consider getting an associate’s degree in pulp and paper technology or a related field.

- Gain experience operating and maintaining machinery.

- Develop strong problem-solving skills.

- Be able to work independently and as part of a team.

- Be physically fit and able to work in a manufacturing environment.