Are you a seasoned Heading Saw Operator seeking a new career path? Discover our professionally built Heading Saw Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

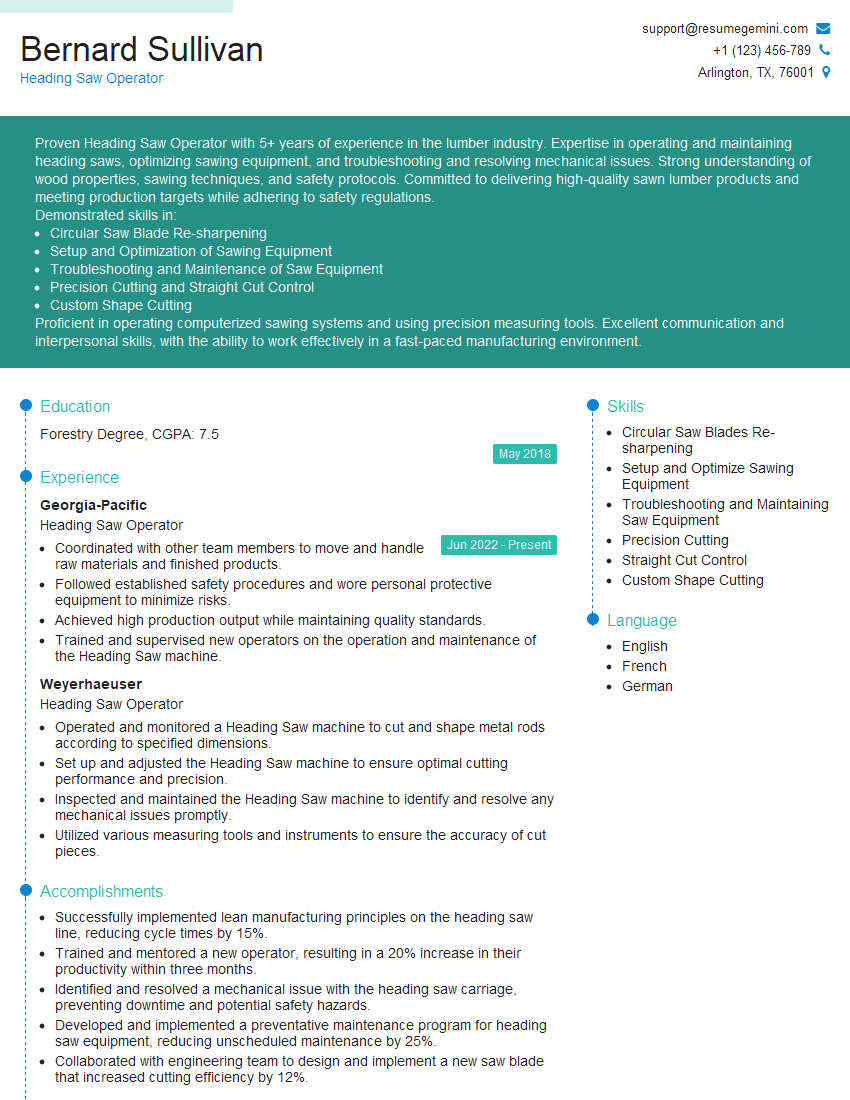

Bernard Sullivan

Heading Saw Operator

Summary

Proven Heading Saw Operator with 5+ years of experience in the lumber industry. Expertise in operating and maintaining heading saws, optimizing sawing equipment, and troubleshooting and resolving mechanical issues. Strong understanding of wood properties, sawing techniques, and safety protocols. Committed to delivering high-quality sawn lumber products and meeting production targets while adhering to safety regulations.

Demonstrated skills in:

- Circular Saw Blade Re-sharpening

- Setup and Optimization of Sawing Equipment

- Troubleshooting and Maintenance of Saw Equipment

- Precision Cutting and Straight Cut Control

- Custom Shape Cutting

Proficient in operating computerized sawing systems and using precision measuring tools. Excellent communication and interpersonal skills, with the ability to work effectively in a fast-paced manufacturing environment.

Education

Forestry Degree

May 2018

Skills

- Circular Saw Blades Re-sharpening

- Setup and Optimize Sawing Equipment

- Troubleshooting and Maintaining Saw Equipment

- Precision Cutting

- Straight Cut Control

- Custom Shape Cutting

Work Experience

Heading Saw Operator

- Coordinated with other team members to move and handle raw materials and finished products.

- Followed established safety procedures and wore personal protective equipment to minimize risks.

- Achieved high production output while maintaining quality standards.

- Trained and supervised new operators on the operation and maintenance of the Heading Saw machine.

Heading Saw Operator

- Operated and monitored a Heading Saw machine to cut and shape metal rods according to specified dimensions.

- Set up and adjusted the Heading Saw machine to ensure optimal cutting performance and precision.

- Inspected and maintained the Heading Saw machine to identify and resolve any mechanical issues promptly.

- Utilized various measuring tools and instruments to ensure the accuracy of cut pieces.

Accomplishments

- Successfully implemented lean manufacturing principles on the heading saw line, reducing cycle times by 15%.

- Trained and mentored a new operator, resulting in a 20% increase in their productivity within three months.

- Identified and resolved a mechanical issue with the heading saw carriage, preventing downtime and potential safety hazards.

- Developed and implemented a preventative maintenance program for heading saw equipment, reducing unscheduled maintenance by 25%.

- Collaborated with engineering team to design and implement a new saw blade that increased cutting efficiency by 12%.

Awards

- Recipient of the Safety Star award for maintaining an impeccable safety record in the sawmill.

- Recognized for outstanding performance in achieving production targets three consecutive quarters.

- Recipient of the Employee of the Year award for exceptional contributions to the sawmill.

- Honored with the Safety Excellence Award for upholding safety standards and promoting a positive safety culture.

Certificates

- OSHA Safety Certification

- Forklift Operator Certification

- ISO 9001 Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heading Saw Operator

- Highlight your expertise: Emphasize your skills and experience in operating heading saws, troubleshooting, and optimizing sawing equipment.

- Quantify your accomplishments: Provide specific examples of how you have improved production efficiency, reduced waste, or resolved complex technical issues.

- Showcase your safety??: Highlight your commitment to safety by mentioning your adherence to safety protocols and practices in the workplace.

- Use industry-specific keywords: Include keywords like ‘heading saw operation,’ ‘circular saw blade sharpening,’ and ‘sawing equipment optimization’ to enhance your resume’s visibility to potential employers.

- Proofread carefully: Ensure your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Heading Saw Operator Resume

- Operate heading saws to cut logs into specified dimensions and shapes, ensuring precision and accuracy.

- Sharpen and maintain circular saw blades to optimize cutting performance and extend blade life.

- Set up and optimize sawing equipment, including feed rates, blade speeds, and cutting angles, to achieve desired results.

- Troubleshoot and resolve mechanical issues with sawing equipment, minimizing downtime and ensuring smooth operation.

- Maintain a clean and organized work area, adhering to safety regulations and industry best practices.

- Monitor and adjust cutting parameters to optimize production efficiency and minimize waste.

- Collaborate with other team members to ensure a seamless production process and meet customer specifications.

Frequently Asked Questions (FAQ’s) For Heading Saw Operator

What is the primary role of a Heading Saw Operator?

A Heading Saw Operator is responsible for operating and maintaining heading saws to cut logs into specified dimensions and shapes, ensuring precision and accuracy. They also sharpen and maintain circular saw blades, set up and optimize sawing equipment, and troubleshoot and resolve mechanical issues.

What are the essential skills required for this role?

Essential skills for a Heading Saw Operator include expertise in operating heading saws, proficiency in circular saw blade sharpening, and the ability to set up, optimize, and troubleshoot sawing equipment. They should also possess excellent mechanical aptitude and a strong understanding of wood properties and sawing techniques.

What industries typically employ Heading Saw Operators?

Heading Saw Operators are primarily employed in the lumber and wood products industry. They work in sawmills, lumberyards, and other facilities where logs are processed and converted into sawn lumber products.

What are the career advancement opportunities for Heading Saw Operators?

With experience and additional training, Heading Saw Operators can advance to supervisory roles, such as Sawmill Supervisor or Production Manager. They can also specialize in specific areas, such as saw blade maintenance or equipment optimization.

What is the average salary range for Heading Saw Operators?

The average salary range for Heading Saw Operators varies depending on factors such as experience, location, and industry. According to Salary.com, the average salary range for Heading Saw Operators in the United States is between $40,000 and $60,000 per year.

What are the safety precautions that Heading Saw Operators must follow?

Heading Saw Operators must adhere to strict safety protocols to minimize the risk of accidents. These precautions include wearing appropriate safety gear, maintaining a clean and organized work area, and following established operating procedures. They must also be trained in proper lockout/tagout procedures to ensure equipment is safely isolated during maintenance or repairs.

What are the physical demands of being a Heading Saw Operator?

Heading Saw Operators must be able to perform physically demanding tasks, such as lifting heavy logs, operating heavy machinery, and standing for extended periods. They must also have good hand-eye coordination and the ability to work in a fast-paced, often noisy environment.

What is the job outlook for Heading Saw Operators?

The job outlook for Heading Saw Operators is expected to be stable in the coming years. As the demand for lumber and wood products continues, there will be a need for skilled operators to operate and maintain sawing equipment.