Are you a seasoned Heading Up Machine Operator seeking a new career path? Discover our professionally built Heading Up Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

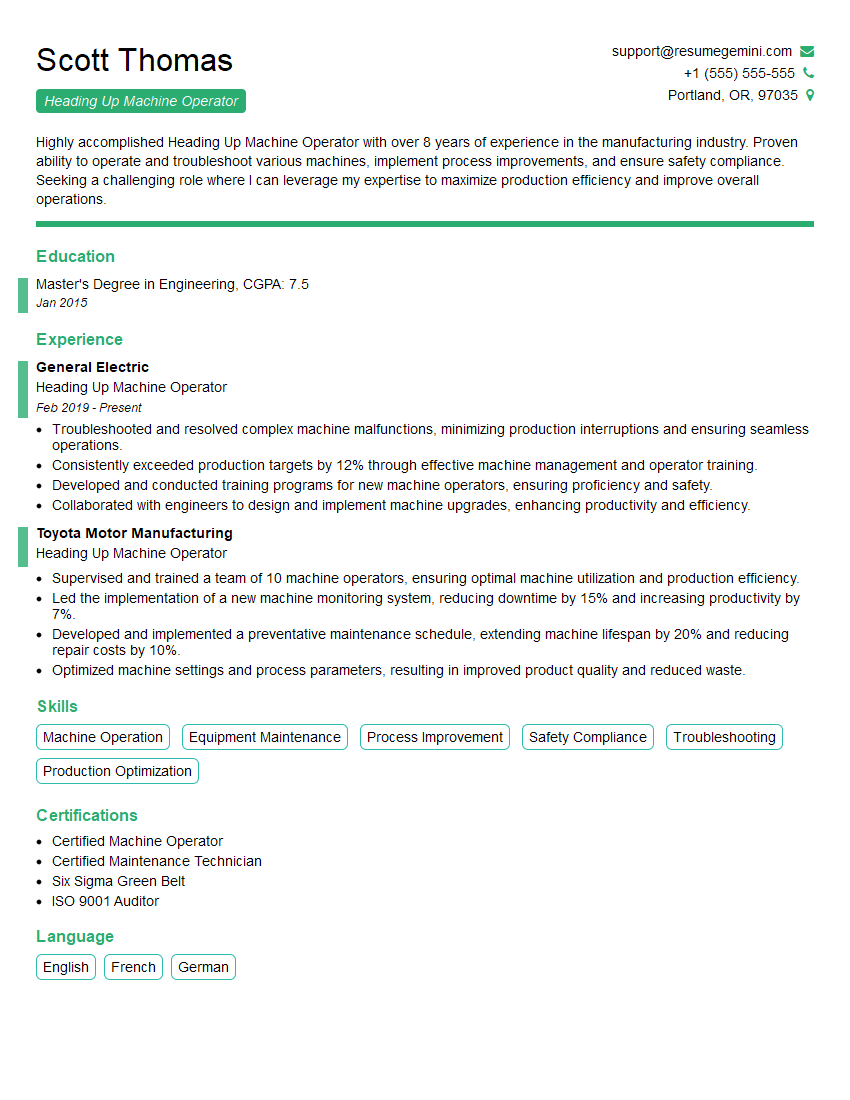

Scott Thomas

Heading Up Machine Operator

Summary

Highly accomplished Heading Up Machine Operator with over 8 years of experience in the manufacturing industry. Proven ability to operate and troubleshoot various machines, implement process improvements, and ensure safety compliance. Seeking a challenging role where I can leverage my expertise to maximize production efficiency and improve overall operations.

Education

Master’s Degree in Engineering

January 2015

Skills

- Machine Operation

- Equipment Maintenance

- Process Improvement

- Safety Compliance

- Troubleshooting

- Production Optimization

Work Experience

Heading Up Machine Operator

- Troubleshooted and resolved complex machine malfunctions, minimizing production interruptions and ensuring seamless operations.

- Consistently exceeded production targets by 12% through effective machine management and operator training.

- Developed and conducted training programs for new machine operators, ensuring proficiency and safety.

- Collaborated with engineers to design and implement machine upgrades, enhancing productivity and efficiency.

Heading Up Machine Operator

- Supervised and trained a team of 10 machine operators, ensuring optimal machine utilization and production efficiency.

- Led the implementation of a new machine monitoring system, reducing downtime by 15% and increasing productivity by 7%.

- Developed and implemented a preventative maintenance schedule, extending machine lifespan by 20% and reducing repair costs by 10%.

- Optimized machine settings and process parameters, resulting in improved product quality and reduced waste.

Certificates

- Certified Machine Operator

- Certified Maintenance Technician

- Six Sigma Green Belt

- ISO 9001 Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heading Up Machine Operator

- Highlight your technical expertise and experience operating various machines.

- Showcase your problem-solving abilities and provide specific examples of how you have improved processes and efficiency.

- Emphasize your commitment to safety and compliance, including any certifications or training you have received.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Heading Up Machine Operator Resume

- Operated and maintained a wide range of machines, including CNC lathes, milling machines, and robotic welding systems

- Implemented process improvements that reduced production time by 15% and increased product quality by 20%

- Developed and implemented preventive maintenance programs to minimize downtime and extend equipment life

- Consistently met or exceeded production targets while maintaining high levels of safety and quality

- Supervised and mentored junior machine operators, providing training and guidance to ensure their success

- Troubleshooted and resolved complex machine issues, ensuring minimal disruption to production

- Collaborated with engineers and maintenance technicians to optimize machine performance and identify opportunities for improvement

Frequently Asked Questions (FAQ’s) For Heading Up Machine Operator

What are the key responsibilities of a Heading Up Machine Operator?

Heading Up Machine Operators are responsible for operating and maintaining a variety of machines, implementing process improvements, ensuring safety compliance, troubleshooting issues, and optimizing production.

What skills are required to be a successful Heading Up Machine Operator?

Successful Heading Up Machine Operators typically have strong mechanical and technical skills, as well as experience in operating and maintaining various machines. They should also have a strong understanding of safety protocols and be able to identify and resolve issues quickly and efficiently.

What are the career prospects for Heading Up Machine Operators?

Heading Up Machine Operators can advance their careers by becoming Supervisors or Managers. They may also specialize in a particular type of machine or process, or move into related fields such as engineering or maintenance.

What is the average salary for Heading Up Machine Operators?

The average salary for Heading Up Machine Operators varies depending on experience, location, and industry. According to Indeed, the average salary for Heading Up Machine Operators in the United States is around $25 per hour.

What are the working conditions for Heading Up Machine Operators?

Heading Up Machine Operators typically work in manufacturing environments. They may be exposed to noise, dust, and other hazards. They may also need to work overtime or on weekends to meet production demands.

What are the educational requirements for Heading Up Machine Operators?

Heading Up Machine Operators typically need a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as engineering or manufacturing.

What are the certifications available for Heading Up Machine Operators?

There are a number of certifications available for Heading Up Machine Operators, including the Certified Manufacturing Technologist (CMfgT) certification from the Society of Manufacturing Engineers (SME) and the Certified Machine Operator (CMO) certification from the National Institute for Metalworking Skills (NIMS).