Are you a seasoned Heat Sealing Machine Operator seeking a new career path? Discover our professionally built Heat Sealing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

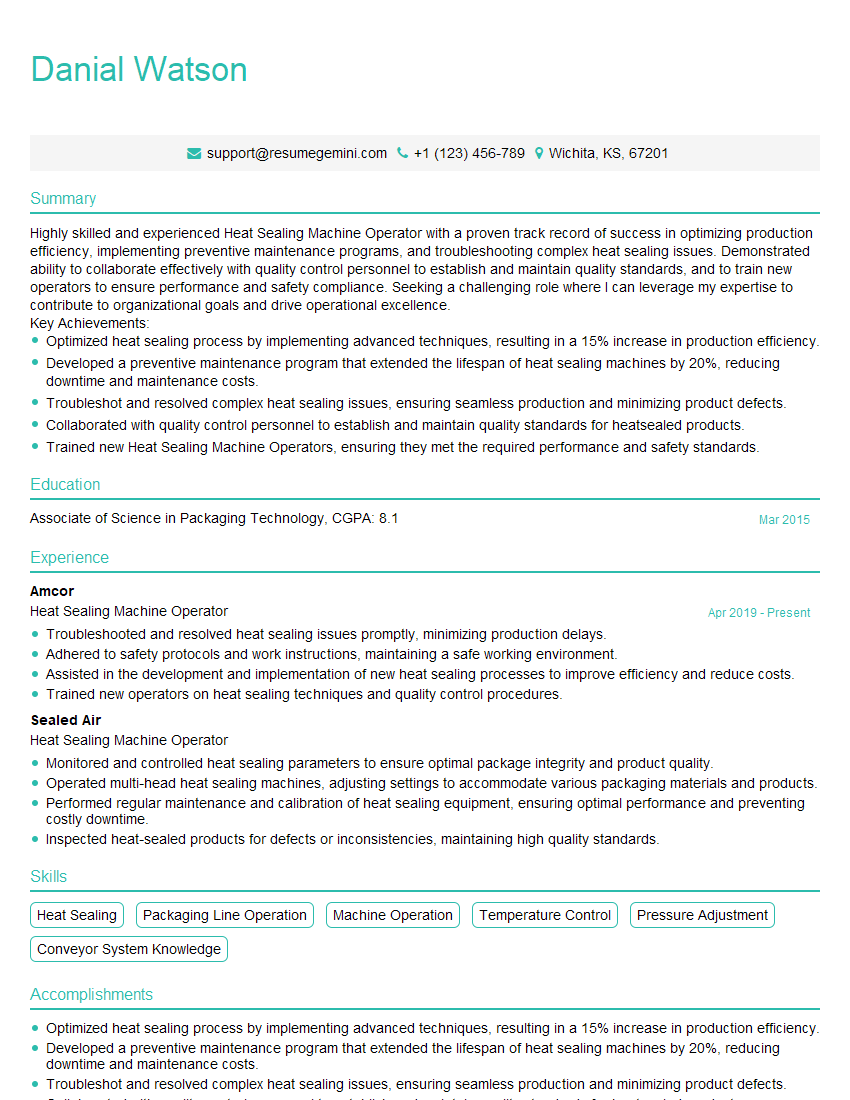

Danial Watson

Heat Sealing Machine Operator

Summary

Highly skilled and experienced Heat Sealing Machine Operator with a proven track record of success in optimizing production efficiency, implementing preventive maintenance programs, and troubleshooting complex heat sealing issues. Demonstrated ability to collaborate effectively with quality control personnel to establish and maintain quality standards, and to train new operators to ensure performance and safety compliance. Seeking a challenging role where I can leverage my expertise to contribute to organizational goals and drive operational excellence.

Key Achievements:

- Optimized heat sealing process by implementing advanced techniques, resulting in a 15% increase in production efficiency.

- Developed a preventive maintenance program that extended the lifespan of heat sealing machines by 20%, reducing downtime and maintenance costs.

- Troubleshot and resolved complex heat sealing issues, ensuring seamless production and minimizing product defects.

- Collaborated with quality control personnel to establish and maintain quality standards for heatsealed products.

- Trained new Heat Sealing Machine Operators, ensuring they met the required performance and safety standards.

Education

Associate of Science in Packaging Technology

March 2015

Skills

- Heat Sealing

- Packaging Line Operation

- Machine Operation

- Temperature Control

- Pressure Adjustment

- Conveyor System Knowledge

Work Experience

Heat Sealing Machine Operator

- Troubleshooted and resolved heat sealing issues promptly, minimizing production delays.

- Adhered to safety protocols and work instructions, maintaining a safe working environment.

- Assisted in the development and implementation of new heat sealing processes to improve efficiency and reduce costs.

- Trained new operators on heat sealing techniques and quality control procedures.

Heat Sealing Machine Operator

- Monitored and controlled heat sealing parameters to ensure optimal package integrity and product quality.

- Operated multi-head heat sealing machines, adjusting settings to accommodate various packaging materials and products.

- Performed regular maintenance and calibration of heat sealing equipment, ensuring optimal performance and preventing costly downtime.

- Inspected heat-sealed products for defects or inconsistencies, maintaining high quality standards.

Accomplishments

- Optimized heat sealing process by implementing advanced techniques, resulting in a 15% increase in production efficiency.

- Developed a preventive maintenance program that extended the lifespan of heat sealing machines by 20%, reducing downtime and maintenance costs.

- Troubleshot and resolved complex heat sealing issues, ensuring seamless production and minimizing product defects.

- Collaborated with quality control personnel to establish and maintain quality standards for heatsealed products.

- Trained new Heat Sealing Machine Operators, ensuring they met the required performance and safety standards.

Awards

- Recognized for achieving exceptional production targets and maintaining high levels of product quality.

- Received an award for outstanding safety practices and commitment to preventing accidents.

- Recognized for exceptional contributions to process improvement and innovation in heat sealing operations.

Certificates

- OSHA Safety Certification

- Heat Sealing Machine Operator Certification

- Quality Assurance Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heat Sealing Machine Operator

- Highlight your technical skills and experience in operating and maintaining heat sealing machines.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Demonstrate your understanding of quality control procedures and standards.

- Emphasize your ability to work independently and as part of a team in a fast-paced production environment.

Essential Experience Highlights for a Strong Heat Sealing Machine Operator Resume

- Operate heat sealing machines to seal a variety of packaging materials, ensuring proper sealing and product integrity.

- Monitor and adjust machine settings, such as temperature, pressure, and conveyor speed, to optimize performance and prevent defects.

- Inspect and maintain heat sealing equipment, including regular cleaning, lubrication, and replacement of worn parts.

- Troubleshoot and resolve mechanical and electrical issues with heat sealing machines, minimizing downtime and ensuring efficient operation.

- Follow established quality control procedures to ensure that sealed products meet specifications and regulatory requirements.

- Collaborate with production and quality control personnel to identify and implement process improvements that enhance efficiency and product quality.

Frequently Asked Questions (FAQ’s) For Heat Sealing Machine Operator

What are the key skills required to be a successful Heat Sealing Machine Operator?

Key skills for a Heat Sealing Machine Operator include a strong understanding of heat sealing principles, proficiency in operating and maintaining heat sealing equipment, attention to detail, and the ability to work independently and as part of a team.

What are the career prospects for Heat Sealing Machine Operators?

Heat Sealing Machine Operators can advance their careers by developing specialized skills, such as troubleshooting complex technical issues or implementing quality control procedures. They may also move into supervisory or management roles.

What are the typical working conditions for Heat Sealing Machine Operators?

Heat Sealing Machine Operators typically work in manufacturing facilities or warehouses. They may be exposed to noise, heat, and repetitive motions.

What is the average salary for Heat Sealing Machine Operators?

According to Glassdoor, the average salary for Heat Sealing Machine Operators in the United States is around $17.50 per hour.

What are some tips for writing a standout Heat Sealing Machine Operator resume?

To write a standout Heat Sealing Machine Operator resume, highlight your technical skills and experience, quantify your accomplishments, demonstrate your understanding of quality control procedures, and emphasize your ability to work independently and as part of a team.

What are some common interview questions for Heat Sealing Machine Operators?

Common interview questions for Heat Sealing Machine Operators include questions about their experience operating and maintaining heat sealing equipment, their knowledge of quality control procedures, and their ability to work in a fast-paced production environment.

What are the safety precautions that Heat Sealing Machine Operators should follow?

Heat Sealing Machine Operators should follow all safety precautions outlined by the manufacturer of the equipment they are operating. These precautions may include wearing appropriate personal protective equipment, such as gloves and safety glasses, and following lockout/tagout procedures when performing maintenance.

What are the latest trends in heat sealing technology?

The latest trends in heat sealing technology include the development of new materials and adhesives that offer improved performance and efficiency. Heat sealing machines are also becoming more automated and connected, allowing for greater control and monitoring of the sealing process.