Are you a seasoned Heat Treat Furnace Operator seeking a new career path? Discover our professionally built Heat Treat Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

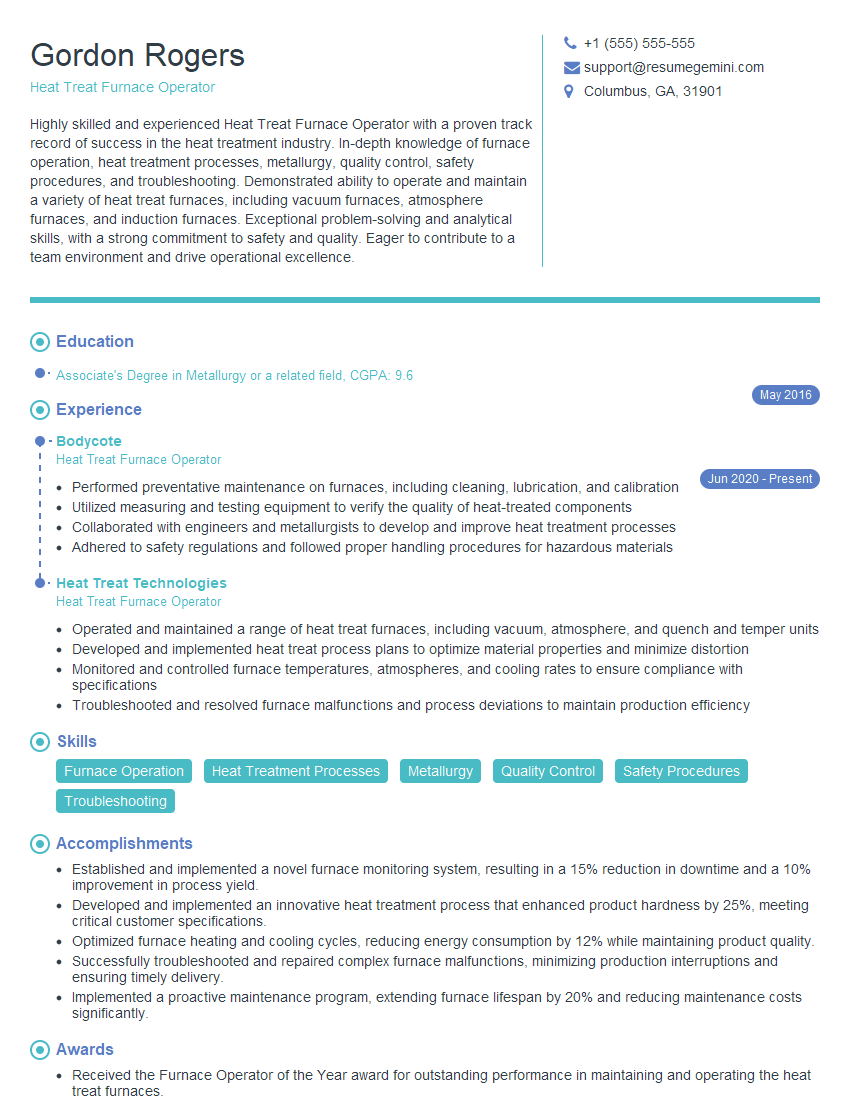

Gordon Rogers

Heat Treat Furnace Operator

Summary

Highly skilled and experienced Heat Treat Furnace Operator with a proven track record of success in the heat treatment industry. In-depth knowledge of furnace operation, heat treatment processes, metallurgy, quality control, safety procedures, and troubleshooting. Demonstrated ability to operate and maintain a variety of heat treat furnaces, including vacuum furnaces, atmosphere furnaces, and induction furnaces. Exceptional problem-solving and analytical skills, with a strong commitment to safety and quality. Eager to contribute to a team environment and drive operational excellence.

Education

Associate’s Degree in Metallurgy or a related field

May 2016

Skills

- Furnace Operation

- Heat Treatment Processes

- Metallurgy

- Quality Control

- Safety Procedures

- Troubleshooting

Work Experience

Heat Treat Furnace Operator

- Performed preventative maintenance on furnaces, including cleaning, lubrication, and calibration

- Utilized measuring and testing equipment to verify the quality of heat-treated components

- Collaborated with engineers and metallurgists to develop and improve heat treatment processes

- Adhered to safety regulations and followed proper handling procedures for hazardous materials

Heat Treat Furnace Operator

- Operated and maintained a range of heat treat furnaces, including vacuum, atmosphere, and quench and temper units

- Developed and implemented heat treat process plans to optimize material properties and minimize distortion

- Monitored and controlled furnace temperatures, atmospheres, and cooling rates to ensure compliance with specifications

- Troubleshooted and resolved furnace malfunctions and process deviations to maintain production efficiency

Accomplishments

- Established and implemented a novel furnace monitoring system, resulting in a 15% reduction in downtime and a 10% improvement in process yield.

- Developed and implemented an innovative heat treatment process that enhanced product hardness by 25%, meeting critical customer specifications.

- Optimized furnace heating and cooling cycles, reducing energy consumption by 12% while maintaining product quality.

- Successfully troubleshooted and repaired complex furnace malfunctions, minimizing production interruptions and ensuring timely delivery.

- Implemented a proactive maintenance program, extending furnace lifespan by 20% and reducing maintenance costs significantly.

Awards

- Received the Furnace Operator of the Year award for outstanding performance in maintaining and operating the heat treat furnaces.

Certificates

- Certified Heat Treatment Technician (CHT)

- National Association of Heat Treaters (NAHT)

- American Society for Metals (ASM)

- Occupational Safety and Health Administration (OSHA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heat Treat Furnace Operator

- Highlight your technical skills and experience in heat treatment processes, including furnace operation, metallurgy, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your problem-solving abilities and provide examples of how you have resolved complex issues in the past.

- Emphasize your commitment to safety and quality, and highlight any relevant certifications or training you have received.

Essential Experience Highlights for a Strong Heat Treat Furnace Operator Resume

- Operate and maintain a variety of heat treat furnaces, including vacuum furnaces, atmosphere furnaces, and induction furnaces

- Monitor and control furnace temperature, atmosphere, and other process parameters to ensure consistent and high-quality heat treatment results

- Load and unload materials into and out of furnaces using proper handling techniques

- Conduct quality control tests on heat-treated materials to ensure they meet specifications

- Maintain a clean and organized work area, and adhere to all safety procedures

- Troubleshoot and resolve furnace malfunctions and other operational issues

- Document furnace operation and maintenance activities, and prepare reports as needed

Frequently Asked Questions (FAQ’s) For Heat Treat Furnace Operator

What are the primary responsibilities of a Heat Treat Furnace Operator?

The primary responsibilities of a Heat Treat Furnace Operator include operating and maintaining heat treat furnaces, monitoring and controlling furnace parameters, loading and unloading materials, conducting quality control tests, troubleshooting furnace malfunctions, and adhering to safety procedures.

What skills are required to be a successful Heat Treat Furnace Operator?

To be a successful Heat Treat Furnace Operator, you will need technical skills in furnace operation, heat treatment processes, metallurgy, and quality control. You should also have strong problem-solving abilities, be detail-oriented, and have a commitment to safety.

What is the work environment of a Heat Treat Furnace Operator like?

Heat Treat Furnace Operators typically work in industrial settings, such as manufacturing plants or heat treatment facilities. The work environment can be hot and noisy, and may involve exposure to hazardous materials. It is important to wear appropriate protective gear and follow all safety procedures to minimize the risk of accidents.

What are the career prospects for a Heat Treat Furnace Operator?

Heat Treat Furnace Operators can advance their careers by gaining experience and developing their skills. With experience, they can move into supervisory or management roles. They can also specialize in a particular type of heat treatment process or material.

What is the salary range for a Heat Treat Furnace Operator?

The salary range for a Heat Treat Furnace Operator can vary depending on experience, skills, and location. According to Indeed, the average salary for a Heat Treat Furnace Operator in the United States is $23.85 per hour.

What are the benefits of working as a Heat Treat Furnace Operator?

Benefits of working as a Heat Treat Furnace Operator can include competitive salaries, overtime pay, health and dental insurance, paid time off, and opportunities for career advancement.