Are you a seasoned Heat Treating Furnace Tender seeking a new career path? Discover our professionally built Heat Treating Furnace Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

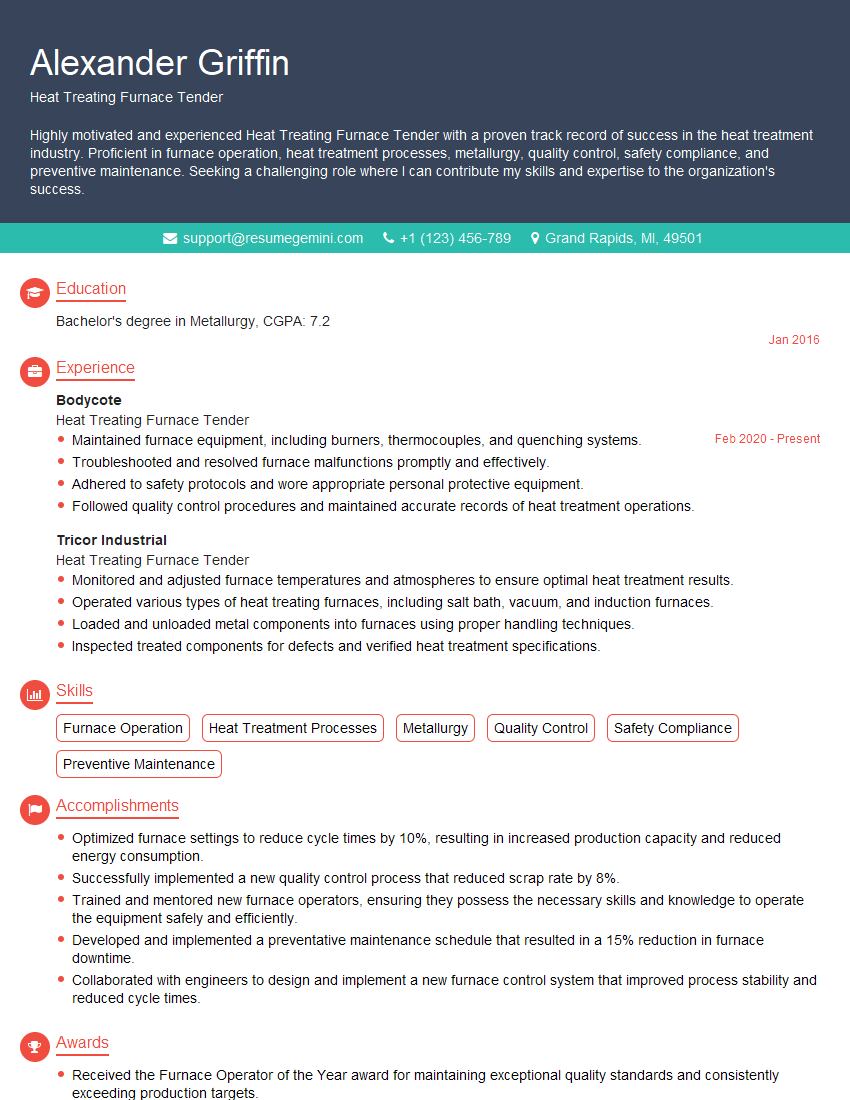

Alexander Griffin

Heat Treating Furnace Tender

Summary

Highly motivated and experienced Heat Treating Furnace Tender with a proven track record of success in the heat treatment industry. Proficient in furnace operation, heat treatment processes, metallurgy, quality control, safety compliance, and preventive maintenance. Seeking a challenging role where I can contribute my skills and expertise to the organization’s success.

Education

Bachelor’s degree in Metallurgy

January 2016

Skills

- Furnace Operation

- Heat Treatment Processes

- Metallurgy

- Quality Control

- Safety Compliance

- Preventive Maintenance

Work Experience

Heat Treating Furnace Tender

- Maintained furnace equipment, including burners, thermocouples, and quenching systems.

- Troubleshooted and resolved furnace malfunctions promptly and effectively.

- Adhered to safety protocols and wore appropriate personal protective equipment.

- Followed quality control procedures and maintained accurate records of heat treatment operations.

Heat Treating Furnace Tender

- Monitored and adjusted furnace temperatures and atmospheres to ensure optimal heat treatment results.

- Operated various types of heat treating furnaces, including salt bath, vacuum, and induction furnaces.

- Loaded and unloaded metal components into furnaces using proper handling techniques.

- Inspected treated components for defects and verified heat treatment specifications.

Accomplishments

- Optimized furnace settings to reduce cycle times by 10%, resulting in increased production capacity and reduced energy consumption.

- Successfully implemented a new quality control process that reduced scrap rate by 8%.

- Trained and mentored new furnace operators, ensuring they possess the necessary skills and knowledge to operate the equipment safely and efficiently.

- Developed and implemented a preventative maintenance schedule that resulted in a 15% reduction in furnace downtime.

- Collaborated with engineers to design and implement a new furnace control system that improved process stability and reduced cycle times.

Awards

- Received the Furnace Operator of the Year award for maintaining exceptional quality standards and consistently exceeding production targets.

- Recognized for developing an innovative maintenance program that extended furnace lifespan by 25%.

- Honored with the Safety Excellence Award for adhering to strict safety protocols and maintaining a hazardfree work environment.

- Received recognition for outstanding performance in managing and coordinating multiple furnace operations simultaneously.

Certificates

- Heat Treatment Certification

- Metallurgy Technician Certification

- Quality Control Technician Certification

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heat Treating Furnace Tender

- Highlight your experience and skills in furnace operation, heat treatment processes, and metallurgy.

- Quantify your accomplishments with specific metrics and results.

- Emphasize your commitment to safety and quality control.

- Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the position.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Heat Treating Furnace Tender Resume

- Operate and monitor heat treating furnaces to ensure proper temperature, atmosphere, and cycle times.

- Perform quality control inspections of heat treated parts to ensure they meet specifications.

- Maintain and calibrate heat treating equipment to ensure optimal performance.

- Troubleshoot and resolve furnace malfunctions to minimize downtime.

- Adhere to safety regulations and ensure a safe working environment.

- Participate in continuous improvement initiatives to enhance productivity and efficiency.

- Collaborate with engineers and metallurgists to optimize heat treatment processes.

Frequently Asked Questions (FAQ’s) For Heat Treating Furnace Tender

What is the role of a Heat Treating Furnace Tender?

Heat Treating Furnace Tenders operate and monitor heat treating furnaces to ensure proper temperature, atmosphere, and cycle times. They also perform quality control inspections of heat treated parts to ensure they meet specifications.

What skills are required to be a successful Heat Treating Furnace Tender?

Successful Heat Treating Furnace Tenders have a strong understanding of furnace operation, heat treatment processes, metallurgy, quality control, safety compliance, and preventive maintenance.

What is the job outlook for Heat Treating Furnace Tenders?

The job outlook for Heat Treating Furnace Tenders is expected to be good over the next several years, due to the increasing demand for heat treated parts in various industries.

What is the average salary for a Heat Treating Furnace Tender?

The average salary for a Heat Treating Furnace Tender is around \$45,000 per year.

What are the career advancement opportunities for Heat Treating Furnace Tenders?

Heat Treating Furnace Tenders can advance their careers by becoming supervisors, quality control inspectors, or metallurgists.

What are the challenges of being a Heat Treating Furnace Tender?

Heat Treating Furnace Tenders work in a hot and noisy environment and may be exposed to hazardous chemicals. They also need to be able to work independently and as part of a team.