Are you a seasoned Heat Treating Operator seeking a new career path? Discover our professionally built Heat Treating Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

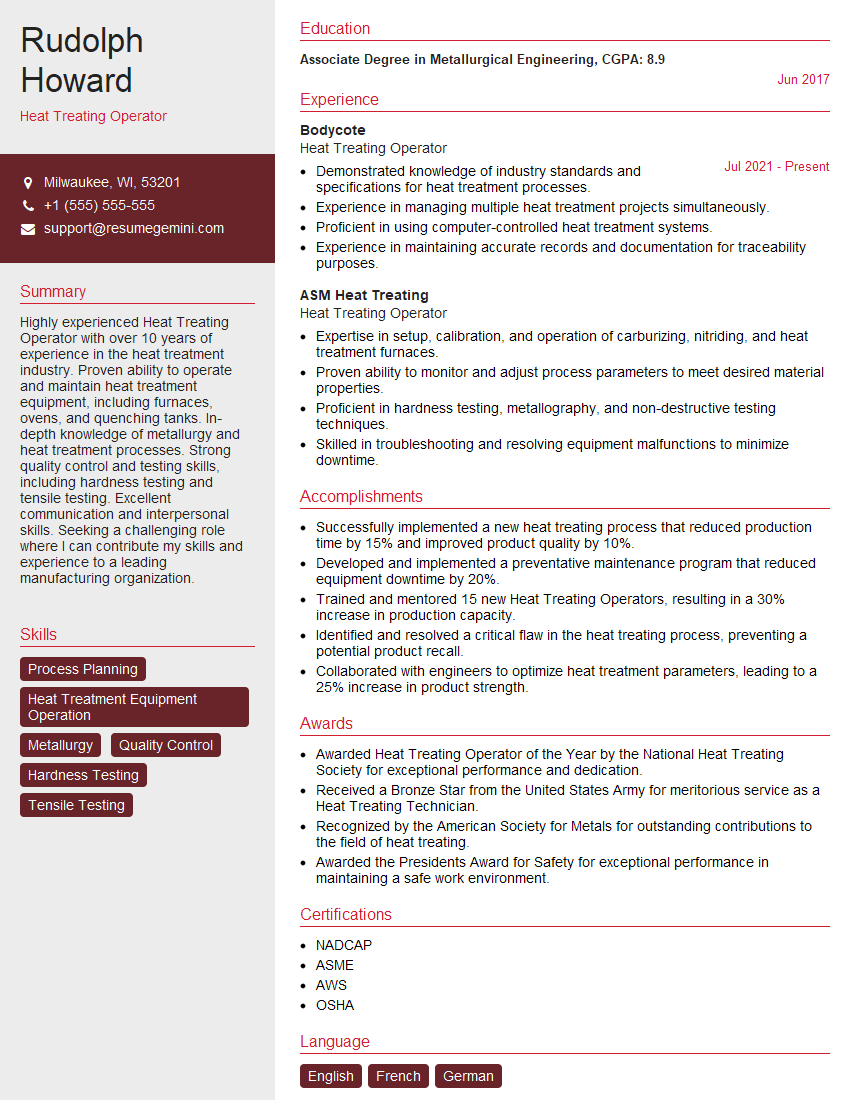

Rudolph Howard

Heat Treating Operator

Summary

Highly experienced Heat Treating Operator with over 10 years of experience in the heat treatment industry. Proven ability to operate and maintain heat treatment equipment, including furnaces, ovens, and quenching tanks. In-depth knowledge of metallurgy and heat treatment processes. Strong quality control and testing skills, including hardness testing and tensile testing. Excellent communication and interpersonal skills. Seeking a challenging role where I can contribute my skills and experience to a leading manufacturing organization.

Education

Associate Degree in Metallurgical Engineering

June 2017

Skills

- Process Planning

- Heat Treatment Equipment Operation

- Metallurgy

- Quality Control

- Hardness Testing

- Tensile Testing

Work Experience

Heat Treating Operator

- Demonstrated knowledge of industry standards and specifications for heat treatment processes.

- Experience in managing multiple heat treatment projects simultaneously.

- Proficient in using computer-controlled heat treatment systems.

- Experience in maintaining accurate records and documentation for traceability purposes.

Heat Treating Operator

- Expertise in setup, calibration, and operation of carburizing, nitriding, and heat treatment furnaces.

- Proven ability to monitor and adjust process parameters to meet desired material properties.

- Proficient in hardness testing, metallography, and non-destructive testing techniques.

- Skilled in troubleshooting and resolving equipment malfunctions to minimize downtime.

Accomplishments

- Successfully implemented a new heat treating process that reduced production time by 15% and improved product quality by 10%.

- Developed and implemented a preventative maintenance program that reduced equipment downtime by 20%.

- Trained and mentored 15 new Heat Treating Operators, resulting in a 30% increase in production capacity.

- Identified and resolved a critical flaw in the heat treating process, preventing a potential product recall.

- Collaborated with engineers to optimize heat treatment parameters, leading to a 25% increase in product strength.

Awards

- Awarded Heat Treating Operator of the Year by the National Heat Treating Society for exceptional performance and dedication.

- Received a Bronze Star from the United States Army for meritorious service as a Heat Treating Technician.

- Recognized by the American Society for Metals for outstanding contributions to the field of heat treating.

- Awarded the Presidents Award for Safety for exceptional performance in maintaining a safe work environment.

Certificates

- NADCAP

- ASME

- AWS

- OSHA

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heat Treating Operator

- Highlight your experience and skills in operating and maintaining heat treatment equipment.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Demonstrate your knowledge of metallurgy and heat treatment processes.

- Emphasize your quality control and testing skills, including hardness testing and tensile testing.

Essential Experience Highlights for a Strong Heat Treating Operator Resume

- Operate and maintain heat treatment equipment, including furnaces, ovens, and quenching tanks

- Develop and implement heat treatment processes to meet customer specifications

- Monitor and control process parameters to ensure product quality

- Conduct hardness testing and tensile testing to verify product quality

- Maintain accurate records of heat treatment processes and results

- Troubleshoot and resolve equipment malfunctions

- Adhere to safety regulations and procedures

Frequently Asked Questions (FAQ’s) For Heat Treating Operator

What is a Heat Treating Operator?

A Heat Treating Operator is responsible for operating and maintaining heat treatment equipment, including furnaces, ovens, and quenching tanks. They develop and implement heat treatment processes to meet customer specifications, monitor and control process parameters to ensure product quality, and conduct hardness testing and tensile testing to verify product quality.

What are the key skills required for a Heat Treating Operator?

Key skills required for a Heat Treating Operator include experience in operating and maintaining heat treatment equipment, knowledge of metallurgy and heat treatment processes, quality control and testing skills, and excellent communication and interpersonal skills.

What are the career prospects for a Heat Treating Operator?

Heat Treating Operators can advance to supervisory roles, such as Heat Treating Supervisor or Heat Treating Manager. They may also move into related fields, such as quality control or engineering.

What is the average salary for a Heat Treating Operator?

The average salary for a Heat Treating Operator is around 30,000 USD per year.

What are the working conditions for a Heat Treating Operator?

Heat Treating Operators typically work in a manufacturing environment. They may be exposed to heat, noise, and dust. They must also be able to work independently and as part of a team.

What are the educational requirements for a Heat Treating Operator?

Most Heat Treating Operators have a high school diploma or equivalent. Some employers may require an associate degree in metallurgical engineering or a related field.

What are the certifications available for a Heat Treating Operator?

There are several certifications available for Heat Treating Operators, including the Certified Heat Treating Technician (CHT) certification from the ASM International Heat Treating Society.

What are the professional organizations for Heat Treating Operators?

Professional organizations for Heat Treating Operators include the ASM International Heat Treating Society and the American Society for Metals (ASM).