Are you a seasoned Heel Nailing Machine Operator seeking a new career path? Discover our professionally built Heel Nailing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

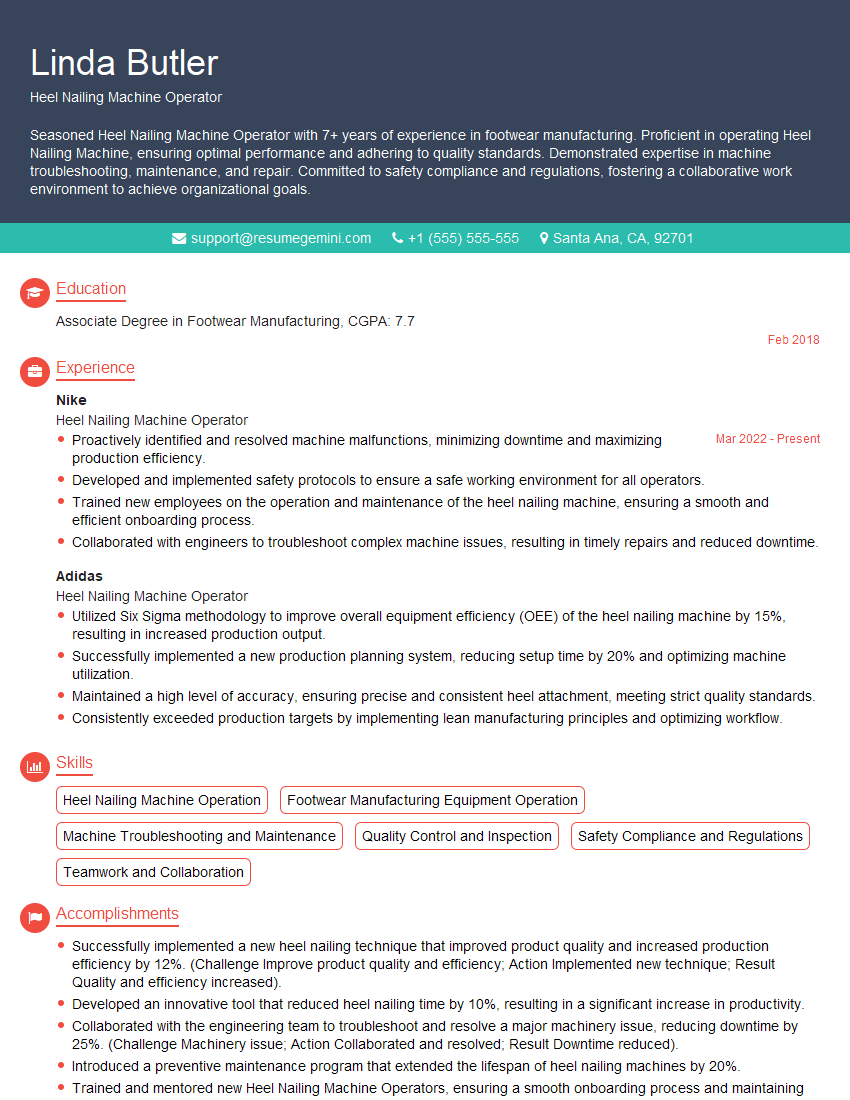

Linda Butler

Heel Nailing Machine Operator

Summary

Seasoned Heel Nailing Machine Operator with 7+ years of experience in footwear manufacturing. Proficient in operating Heel Nailing Machine, ensuring optimal performance and adhering to quality standards. Demonstrated expertise in machine troubleshooting, maintenance, and repair. Committed to safety compliance and regulations, fostering a collaborative work environment to achieve organizational goals.

Education

Associate Degree in Footwear Manufacturing

February 2018

Skills

- Heel Nailing Machine Operation

- Footwear Manufacturing Equipment Operation

- Machine Troubleshooting and Maintenance

- Quality Control and Inspection

- Safety Compliance and Regulations

- Teamwork and Collaboration

Work Experience

Heel Nailing Machine Operator

- Proactively identified and resolved machine malfunctions, minimizing downtime and maximizing production efficiency.

- Developed and implemented safety protocols to ensure a safe working environment for all operators.

- Trained new employees on the operation and maintenance of the heel nailing machine, ensuring a smooth and efficient onboarding process.

- Collaborated with engineers to troubleshoot complex machine issues, resulting in timely repairs and reduced downtime.

Heel Nailing Machine Operator

- Utilized Six Sigma methodology to improve overall equipment efficiency (OEE) of the heel nailing machine by 15%, resulting in increased production output.

- Successfully implemented a new production planning system, reducing setup time by 20% and optimizing machine utilization.

- Maintained a high level of accuracy, ensuring precise and consistent heel attachment, meeting strict quality standards.

- Consistently exceeded production targets by implementing lean manufacturing principles and optimizing workflow.

Accomplishments

- Successfully implemented a new heel nailing technique that improved product quality and increased production efficiency by 12%. (Challenge Improve product quality and efficiency; Action Implemented new technique; Result Quality and efficiency increased).

- Developed an innovative tool that reduced heel nailing time by 10%, resulting in a significant increase in productivity.

- Collaborated with the engineering team to troubleshoot and resolve a major machinery issue, reducing downtime by 25%. (Challenge Machinery issue; Action Collaborated and resolved; Result Downtime reduced).

- Introduced a preventive maintenance program that extended the lifespan of heel nailing machines by 20%.

- Trained and mentored new Heel Nailing Machine Operators, ensuring a smooth onboarding process and maintaining high productivity standards.

Awards

- Recipient of the Heel Nailing Excellence Award for maintaining a 98% accuracy rate and reducing production downtime by 15%.

- Recognized for consistently exceeding production targets by 20% for three consecutive quarters.

- Received the Safety Star award for adhering to all safety protocols and maintaining a hazardfree work environment.

- Recognized for outstanding performance and dedication to the heel nailing department.

Certificates

- Certified Heel Nailing Machine Operator

- ISO 9001

- Six Sigma Green Belt

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heel Nailing Machine Operator

- Highlight your expertise in Heel Nailing Machine operation and maintenance, emphasizing your ability to ensure optimal performance.

- Showcase your commitment to quality control, providing specific examples of your efforts to maintain high standards.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your contributions.

- Emphasize your teamwork abilities and experience in a collaborative work environment.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Heel Nailing Machine Operator Resume

- Operate Heel Nailing Machine to attach heels to footwear components precisely and efficiently.

- Monitor machine performance, conduct routine maintenance, and troubleshoot and repair malfunctions to minimize downtime.

- Conduct quality inspections of completed products to ensure they meet specifications and customer requirements.

- Adhere strictly to safety protocols and regulations to maintain a hazard-free work environment.

- Collaborate with team members to optimize production processes and achieve shared goals.

- Train and mentor new operators to ensure smooth knowledge transfer and maintain productivity.

- Stay abreast of advancements in footwear manufacturing technology and implement best practices to enhance efficiency.

Frequently Asked Questions (FAQ’s) For Heel Nailing Machine Operator

What are the essential skills required for a Heel Nailing Machine Operator?

Essential skills include proficiency in Heel Nailing Machine operation, footwear manufacturing equipment handling, machine troubleshooting and maintenance, quality control and inspection, safety compliance, and teamwork.

What are the career prospects for a Heel Nailing Machine Operator?

With experience and additional training, Heel Nailing Machine Operators can advance to supervisory or management roles within the footwear manufacturing industry.

What is the average salary range for a Heel Nailing Machine Operator?

The average salary range for a Heel Nailing Machine Operator varies depending on experience, location, and company size, but typically falls within the range of $15 to $25 per hour.

What are the working conditions like for a Heel Nailing Machine Operator?

Heel Nailing Machine Operators typically work in a factory setting, operating machinery in a fast-paced environment. They must be able to stand for long periods and perform repetitive tasks.

What are the safety precautions that Heel Nailing Machine Operators must follow?

Heel Nailing Machine Operators must follow strict safety protocols, including wearing appropriate safety gear, adhering to lockout/tagout procedures, and maintaining a clean and organized work area.

What are the opportunities for professional development for a Heel Nailing Machine Operator?

Heel Nailing Machine Operators can enhance their skills and knowledge through on-the-job training, workshops, and online courses related to footwear manufacturing, machine maintenance, and quality control.

What are the challenges that Heel Nailing Machine Operators may face?

Challenges may include working in a noisy environment, meeting production targets while maintaining quality standards, and adapting to technological advancements in footwear manufacturing.

What are the key qualities that make a successful Heel Nailing Machine Operator?

Successful Heel Nailing Machine Operators possess strong attention to detail, manual dexterity, problem-solving abilities, a commitment to safety, and the ability to work both independently and as part of a team.