Are you a seasoned Hemstitching Machine Operator seeking a new career path? Discover our professionally built Hemstitching Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

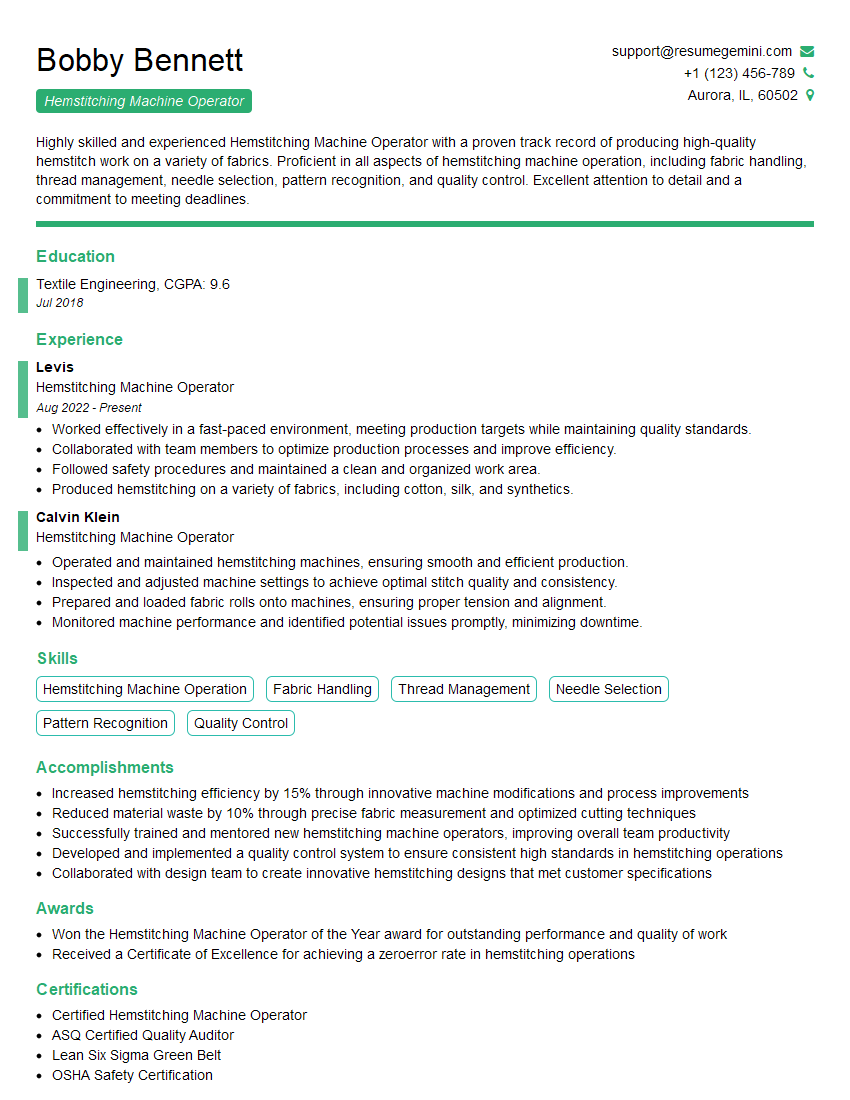

Bobby Bennett

Hemstitching Machine Operator

Summary

Highly skilled and experienced Hemstitching Machine Operator with a proven track record of producing high-quality hemstitch work on a variety of fabrics. Proficient in all aspects of hemstitching machine operation, including fabric handling, thread management, needle selection, pattern recognition, and quality control. Excellent attention to detail and a commitment to meeting deadlines.

Education

Textile Engineering

July 2018

Skills

- Hemstitching Machine Operation

- Fabric Handling

- Thread Management

- Needle Selection

- Pattern Recognition

- Quality Control

Work Experience

Hemstitching Machine Operator

- Worked effectively in a fast-paced environment, meeting production targets while maintaining quality standards.

- Collaborated with team members to optimize production processes and improve efficiency.

- Followed safety procedures and maintained a clean and organized work area.

- Produced hemstitching on a variety of fabrics, including cotton, silk, and synthetics.

Hemstitching Machine Operator

- Operated and maintained hemstitching machines, ensuring smooth and efficient production.

- Inspected and adjusted machine settings to achieve optimal stitch quality and consistency.

- Prepared and loaded fabric rolls onto machines, ensuring proper tension and alignment.

- Monitored machine performance and identified potential issues promptly, minimizing downtime.

Accomplishments

- Increased hemstitching efficiency by 15% through innovative machine modifications and process improvements

- Reduced material waste by 10% through precise fabric measurement and optimized cutting techniques

- Successfully trained and mentored new hemstitching machine operators, improving overall team productivity

- Developed and implemented a quality control system to ensure consistent high standards in hemstitching operations

- Collaborated with design team to create innovative hemstitching designs that met customer specifications

Awards

- Won the Hemstitching Machine Operator of the Year award for outstanding performance and quality of work

- Received a Certificate of Excellence for achieving a zeroerror rate in hemstitching operations

Certificates

- Certified Hemstitching Machine Operator

- ASQ Certified Quality Auditor

- Lean Six Sigma Green Belt

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hemstitching Machine Operator

- Highlight your experience and skills in operating hemstitching machines.

- Showcase your knowledge of different fabrics and how to handle them properly.

- Emphasize your attention to detail and commitment to producing high-quality work.

- Provide examples of your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Hemstitching Machine Operator Resume

- Operate and maintain hemstitching machines to produce high-quality hems on a variety of fabrics.

- Handle and prepare fabrics for hemstitching, including measuring, cutting, and feeding fabrics into the machine.

- Manage thread tension and needle size to ensure optimal hemstitch quality.

- Inspect hemstitched products for quality and ensure they meet specifications.

- Identify and resolve any problems with the hemstitching machine or materials.

- Maintain a clean and organized work area.

- Follow safety procedures and wear appropriate safety gear.

Frequently Asked Questions (FAQ’s) For Hemstitching Machine Operator

What is a hemstitch machine?

A hemstitch machine is a specialized sewing machine used to create hemstitching, a decorative and functional sewing technique that creates a series of small, evenly spaced stitches along the edge of a fabric.

What are the benefits of hemstitching?

Hemstitching adds a decorative touch to garments and other textile products. It also strengthens the hem, making it less likely to fray or unravel.

What types of fabrics can be hemstitched?

Hemstitching can be applied to a wide variety of fabrics, including cotton, linen, silk, and wool. However, it is most commonly used on lightweight to medium-weight fabrics.

What is the difference between hemstitching and overlocking?

Hemstitching is a decorative stitch that creates a series of small, evenly spaced stitches along the edge of a fabric. Overlocking, on the other hand, is a functional stitch that is used to finish the edges of a fabric to prevent fraying or unraveling.

What are the career opportunities for hemstitching machine operators?

Hemstitching machine operators can work in a variety of settings, including garment factories, textile mills, and home sewing businesses. They can also work as freelance hemstitchers.

What are the salary expectations for hemstitching machine operators?

The salary expectations for hemstitching machine operators vary depending on their experience, skills, and location. However, according to Indeed, the average salary for a hemstitching machine operator in the United States is $15.83 per hour.