Are you a seasoned Hobbing Machine Operator seeking a new career path? Discover our professionally built Hobbing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

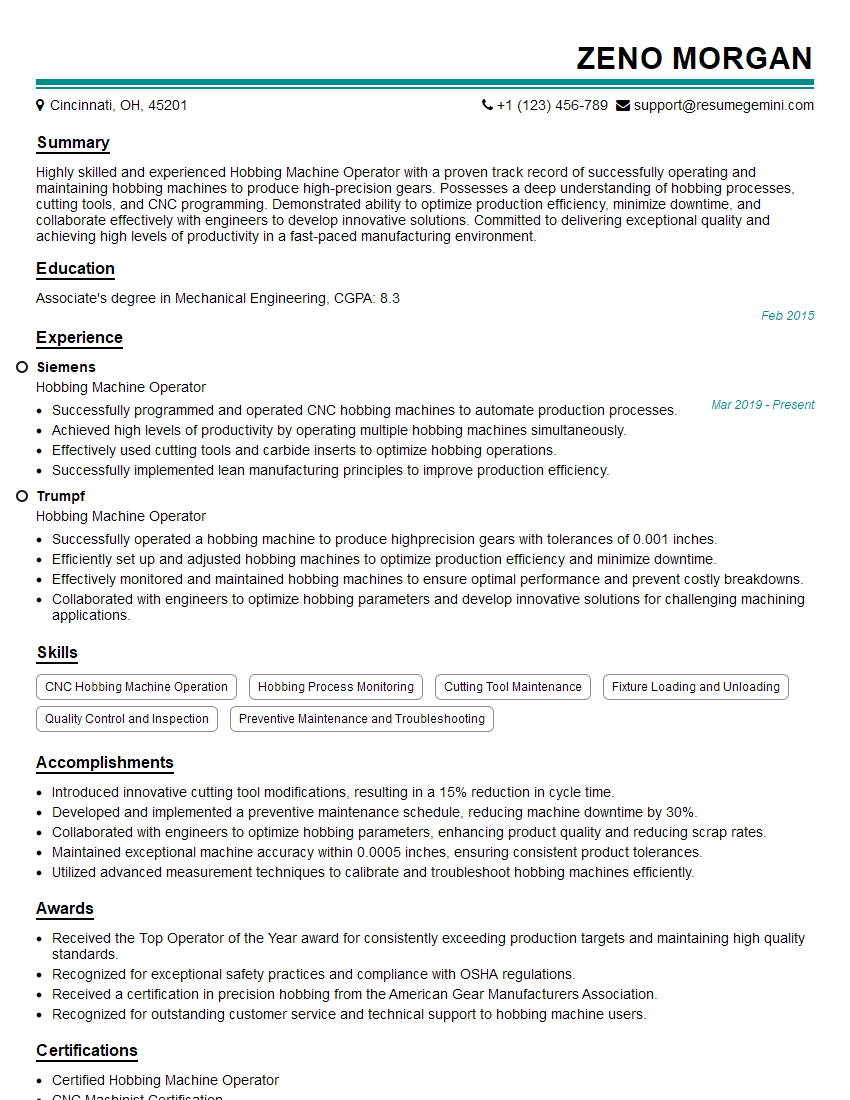

Zeno Morgan

Hobbing Machine Operator

Summary

Highly skilled and experienced Hobbing Machine Operator with a proven track record of successfully operating and maintaining hobbing machines to produce high-precision gears. Possesses a deep understanding of hobbing processes, cutting tools, and CNC programming. Demonstrated ability to optimize production efficiency, minimize downtime, and collaborate effectively with engineers to develop innovative solutions. Committed to delivering exceptional quality and achieving high levels of productivity in a fast-paced manufacturing environment.

Education

Associate’s degree in Mechanical Engineering

February 2015

Skills

- CNC Hobbing Machine Operation

- Hobbing Process Monitoring

- Cutting Tool Maintenance

- Fixture Loading and Unloading

- Quality Control and Inspection

- Preventive Maintenance and Troubleshooting

Work Experience

Hobbing Machine Operator

- Successfully programmed and operated CNC hobbing machines to automate production processes.

- Achieved high levels of productivity by operating multiple hobbing machines simultaneously.

- Effectively used cutting tools and carbide inserts to optimize hobbing operations.

- Successfully implemented lean manufacturing principles to improve production efficiency.

Hobbing Machine Operator

- Successfully operated a hobbing machine to produce highprecision gears with tolerances of 0.001 inches.

- Efficiently set up and adjusted hobbing machines to optimize production efficiency and minimize downtime.

- Effectively monitored and maintained hobbing machines to ensure optimal performance and prevent costly breakdowns.

- Collaborated with engineers to optimize hobbing parameters and develop innovative solutions for challenging machining applications.

Accomplishments

- Introduced innovative cutting tool modifications, resulting in a 15% reduction in cycle time.

- Developed and implemented a preventive maintenance schedule, reducing machine downtime by 30%.

- Collaborated with engineers to optimize hobbing parameters, enhancing product quality and reducing scrap rates.

- Maintained exceptional machine accuracy within 0.0005 inches, ensuring consistent product tolerances.

- Utilized advanced measurement techniques to calibrate and troubleshoot hobbing machines efficiently.

Awards

- Received the Top Operator of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for exceptional safety practices and compliance with OSHA regulations.

- Received a certification in precision hobbing from the American Gear Manufacturers Association.

- Recognized for outstanding customer service and technical support to hobbing machine users.

Certificates

- Certified Hobbing Machine Operator

- CNC Machinist Certification

- ISO 9001 Quality Management Certification

- ASME B17.1 Hobbing Machine Standard Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hobbing Machine Operator

- Highlight your technical skills and experience in operating and maintaining hobbing machines

- Quantify your accomplishments with specific metrics, such as percentage improvements in production efficiency or reduction in downtime

- Demonstrate your understanding of hobbing processes, cutting tools, and CNC programming

- Showcase your ability to work independently and as part of a team, and your commitment to delivering exceptional quality

Essential Experience Highlights for a Strong Hobbing Machine Operator Resume

- Set up and adjust hobbing machines to optimize production efficiency and minimize downtime

- Monitor and maintain hobbing machines to ensure optimal performance and prevent costly breakdowns

- Collaborate with engineers to optimize hobbing parameters and develop innovative solutions for challenging machining applications

- Effectively use cutting tools and carbide inserts to optimize hobbing operations

- Implement lean manufacturing principles to improve production efficiency

- Conduct regular inspections and maintenance to ensure that machines are operating at peak performance

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain productivity

Frequently Asked Questions (FAQ’s) For Hobbing Machine Operator

What are the primary duties and responsibilities of a Hobbing Machine Operator?

Hobbing Machine Operators are responsible for setting up, operating, and maintaining hobbing machines to produce high-precision gears. They also monitor and maintain the machines to ensure optimal performance, troubleshoot and resolve machine malfunctions, and implement lean manufacturing principles to improve production efficiency.

What are the key skills required to be a successful Hobbing Machine Operator?

Successful Hobbing Machine Operators typically possess a combination of technical skills and experience in operating and maintaining hobbing machines. They also have a strong understanding of hobbing processes, cutting tools, and CNC programming. Additionally, they are able to work independently and as part of a team, and are committed to delivering exceptional quality.

What are the career prospects for Hobbing Machine Operators?

Hobbing Machine Operators can advance their careers by developing their skills and experience in operating and maintaining more complex hobbing machines. They can also move into supervisory or management roles, or become involved in research and development of new hobbing technologies.

What is the work environment of a Hobbing Machine Operator like?

Hobbing Machine Operators typically work in a manufacturing environment, often in a machine shop or factory setting. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What is the salary range for Hobbing Machine Operators?

The salary range for Hobbing Machine Operators can vary depending on their experience, skills, and location. According to Indeed, the average salary for Hobbing Machine Operators in the United States is around $27,000 per year.