Are you a seasoned Hobbing Press Operator seeking a new career path? Discover our professionally built Hobbing Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

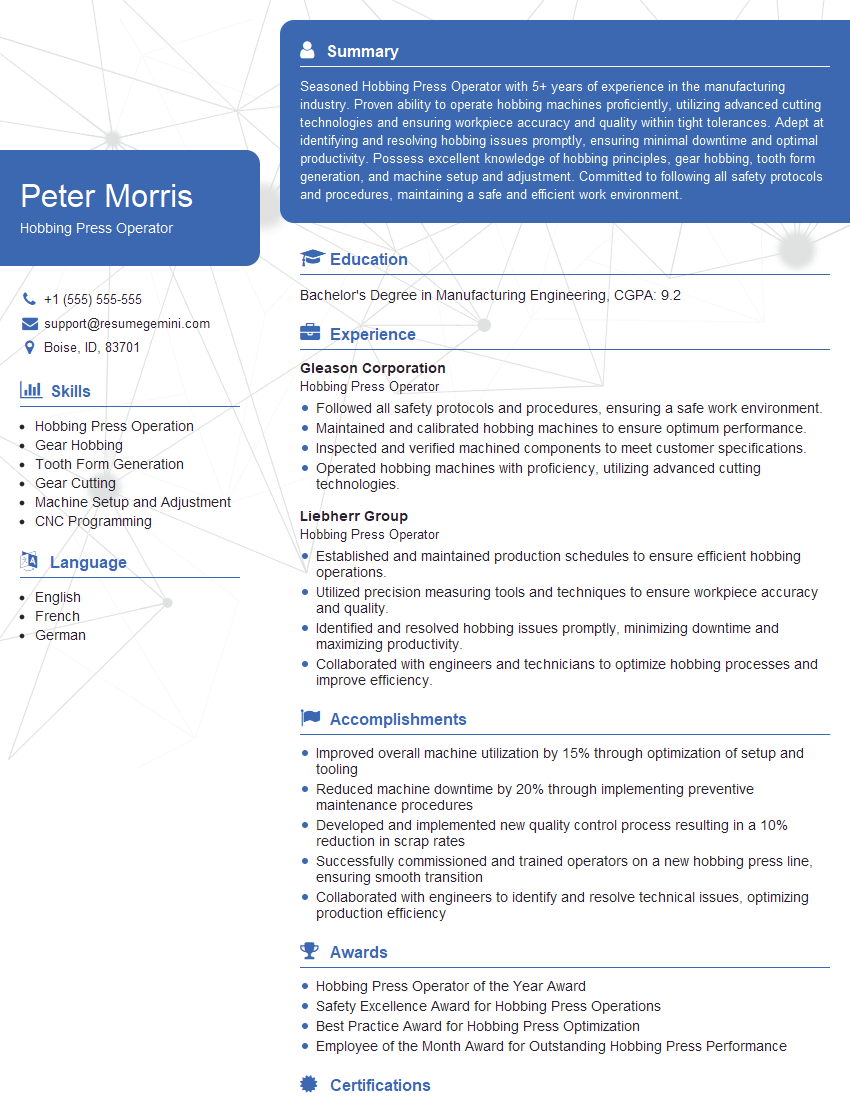

Peter Morris

Hobbing Press Operator

Summary

Seasoned Hobbing Press Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate hobbing machines proficiently, utilizing advanced cutting technologies and ensuring workpiece accuracy and quality within tight tolerances. Adept at identifying and resolving hobbing issues promptly, ensuring minimal downtime and optimal productivity. Possess excellent knowledge of hobbing principles, gear hobbing, tooth form generation, and machine setup and adjustment. Committed to following all safety protocols and procedures, maintaining a safe and efficient work environment.

Education

Bachelor’s Degree in Manufacturing Engineering

May 2019

Skills

- Hobbing Press Operation

- Gear Hobbing

- Tooth Form Generation

- Gear Cutting

- Machine Setup and Adjustment

- CNC Programming

Work Experience

Hobbing Press Operator

- Followed all safety protocols and procedures, ensuring a safe work environment.

- Maintained and calibrated hobbing machines to ensure optimum performance.

- Inspected and verified machined components to meet customer specifications.

- Operated hobbing machines with proficiency, utilizing advanced cutting technologies.

Hobbing Press Operator

- Established and maintained production schedules to ensure efficient hobbing operations.

- Utilized precision measuring tools and techniques to ensure workpiece accuracy and quality.

- Identified and resolved hobbing issues promptly, minimizing downtime and maximizing productivity.

- Collaborated with engineers and technicians to optimize hobbing processes and improve efficiency.

Accomplishments

- Improved overall machine utilization by 15% through optimization of setup and tooling

- Reduced machine downtime by 20% through implementing preventive maintenance procedures

- Developed and implemented new quality control process resulting in a 10% reduction in scrap rates

- Successfully commissioned and trained operators on a new hobbing press line, ensuring smooth transition

- Collaborated with engineers to identify and resolve technical issues, optimizing production efficiency

Awards

- Hobbing Press Operator of the Year Award

- Safety Excellence Award for Hobbing Press Operations

- Best Practice Award for Hobbing Press Optimization

- Employee of the Month Award for Outstanding Hobbing Press Performance

Certificates

- Certified Hobbing Press Operator (CHPO)

- Gear Manufacturing Certification (GMC)

- CNC Machining Certification

- ISO 9001:2015 Internal Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hobbing Press Operator

- Highlight your experience and skills in hobbing press operation, gear hobbing, tooth form generation, and gear cutting.

- Showcase your understanding of machine setup and adjustment, as well as CNC programming.

- Emphasize your ability to identify and resolve hobbing issues quickly and effectively.

- Demonstrate your commitment to safety and your attention to detail.

Essential Experience Highlights for a Strong Hobbing Press Operator Resume

- Set up and operate hobbing machines to produce gears and other precision components.

- Established and maintained production schedules to ensure efficient hobbing operations.

- Utilized precision measuring tools and techniques to ensure workpiece accuracy and quality.

- Identified and resolved hobbing issues promptly, minimizing downtime and maximizing productivity.

- Collaborated with engineers and technicians to optimize hobbing processes and improve efficiency.

- Followed all safety protocols and procedures, ensuring a safe work environment.

- Maintained and calibrated hobbing machines to ensure optimum performance.

Frequently Asked Questions (FAQ’s) For Hobbing Press Operator

What is the role of a Hobbing Press Operator?

A Hobbing Press Operator is responsible for setting up, operating, and maintaining hobbing machines used in the manufacturing of gears and other precision components.

What are the key skills required for a Hobbing Press Operator?

The key skills required for a Hobbing Press Operator include hobbing press operation, gear hobbing, tooth form generation, gear cutting, machine setup and adjustment, and CNC programming.

What is the typical work environment for a Hobbing Press Operator?

Hobbing Press Operators typically work in manufacturing facilities, operating hobbing machines in a production environment.

What are the career prospects for a Hobbing Press Operator?

Hobbing Press Operators with experience and expertise can advance to supervisory or management roles in the manufacturing industry.

How can I prepare for a career as a Hobbing Press Operator?

To prepare for a career as a Hobbing Press Operator, you can pursue a degree in manufacturing engineering or a related field, and gain hands-on experience through internships or apprenticeships.

What are the safety precautions that a Hobbing Press Operator should follow?

Hobbing Press Operators should follow all safety protocols and procedures, wear appropriate safety gear, and be aware of the potential hazards associated with operating heavy machinery.

What are the industry trends that Hobbing Press Operators should be aware of?

Hobbing Press Operators should be aware of industry trends such as the increasing use of automation and the adoption of new technologies in manufacturing.