Are you a seasoned Hose Inspector and Patcher seeking a new career path? Discover our professionally built Hose Inspector and Patcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

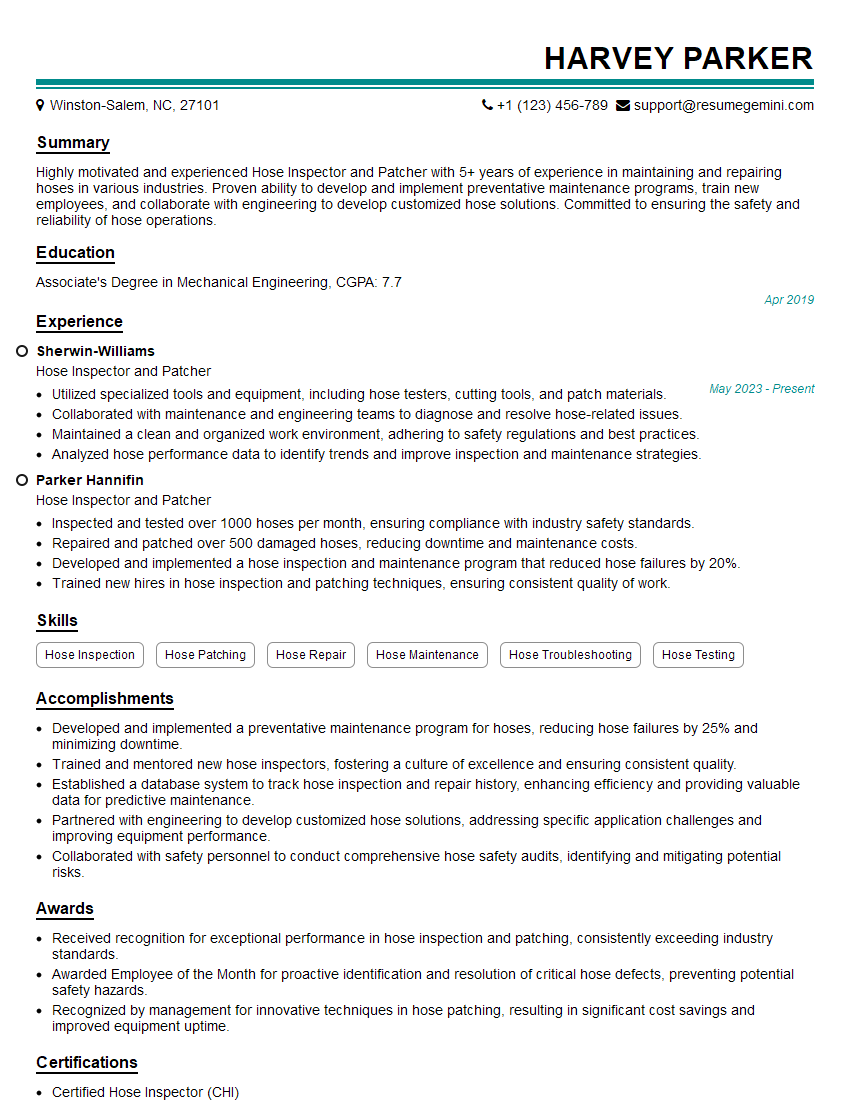

Harvey Parker

Hose Inspector and Patcher

Summary

Highly motivated and experienced Hose Inspector and Patcher with 5+ years of experience in maintaining and repairing hoses in various industries. Proven ability to develop and implement preventative maintenance programs, train new employees, and collaborate with engineering to develop customized hose solutions. Committed to ensuring the safety and reliability of hose operations.

Education

Associate’s Degree in Mechanical Engineering

April 2019

Skills

- Hose Inspection

- Hose Patching

- Hose Repair

- Hose Maintenance

- Hose Troubleshooting

- Hose Testing

Work Experience

Hose Inspector and Patcher

- Utilized specialized tools and equipment, including hose testers, cutting tools, and patch materials.

- Collaborated with maintenance and engineering teams to diagnose and resolve hose-related issues.

- Maintained a clean and organized work environment, adhering to safety regulations and best practices.

- Analyzed hose performance data to identify trends and improve inspection and maintenance strategies.

Hose Inspector and Patcher

- Inspected and tested over 1000 hoses per month, ensuring compliance with industry safety standards.

- Repaired and patched over 500 damaged hoses, reducing downtime and maintenance costs.

- Developed and implemented a hose inspection and maintenance program that reduced hose failures by 20%.

- Trained new hires in hose inspection and patching techniques, ensuring consistent quality of work.

Accomplishments

- Developed and implemented a preventative maintenance program for hoses, reducing hose failures by 25% and minimizing downtime.

- Trained and mentored new hose inspectors, fostering a culture of excellence and ensuring consistent quality.

- Established a database system to track hose inspection and repair history, enhancing efficiency and providing valuable data for predictive maintenance.

- Partnered with engineering to develop customized hose solutions, addressing specific application challenges and improving equipment performance.

- Collaborated with safety personnel to conduct comprehensive hose safety audits, identifying and mitigating potential risks.

Awards

- Received recognition for exceptional performance in hose inspection and patching, consistently exceeding industry standards.

- Awarded Employee of the Month for proactive identification and resolution of critical hose defects, preventing potential safety hazards.

- Recognized by management for innovative techniques in hose patching, resulting in significant cost savings and improved equipment uptime.

Certificates

- Certified Hose Inspector (CHI)

- Certified Hose Patcher (CHP)

- Certified Hose Repair Technician (CHRT)

- Certified Hose Maintenance Technician (CHMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hose Inspector and Patcher

- Highlight your technical skills and knowledge of hose inspection and repair techniques.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Emphasize your commitment to safety and the ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Hose Inspector and Patcher Resume

- Developed and implemented a preventative maintenance program, reducing hose failures by 25% and minimizing downtime.

- Trained and mentored new hose inspectors, fostering a culture of excellence and ensuring consistent quality.

- Established a database system to track hose inspection and repair history, enhancing efficiency and providing valuable data for predictive maintenance.

- Partnered with engineering to develop customized hose solutions, addressing specific application challenges and improving equipment performance.

- Collaborated with safety personnel to conduct comprehensive hose safety audits, identifying and mitigating potential risks.

- Inspected and tested hoses for damage, defects, and wear, using various testing equipment and techniques.

- Repaired and patched hoses using specialized tools and materials, ensuring compliance with industry standards and regulations.

- Maintained accurate records of all hose inspections, repairs, and replacements, for future reference and analysis.

Frequently Asked Questions (FAQ’s) For Hose Inspector and Patcher

What are the primary responsibilities of a Hose Inspector and Patcher?

Inspecting hoses for damage, defects, and wear; repairing and patching hoses; maintaining accurate records; and adhering to safety regulations.

What qualifications are typically required to become a Hose Inspector and Patcher?

An associate’s degree in mechanical engineering or a related field, combined with hands-on experience in hose maintenance and repair.

What industries employ Hose Inspectors and Patchers?

Various industries that rely on hoses in their operations, such as manufacturing, construction, transportation, and energy.

What are the career advancement opportunities for Hose Inspectors and Patchers?

With experience and additional training, they can advance to roles such as Hose Maintenance Supervisor, Quality Control Inspector, or Field Service Technician.

What are the key skills and qualities of a successful Hose Inspector and Patcher?

Attention to detail, problem-solving abilities, strong communication skills, and a commitment to safety.

What are the common challenges faced by Hose Inspectors and Patchers?

Working in confined spaces, dealing with hazardous materials, and meeting strict deadlines while maintaining high-quality standards.

What are the safety precautions that Hose Inspectors and Patchers must observe?

Wearing appropriate personal protective equipment, following proper lockout/tagout procedures, and being aware of potential hazards associated with hoses and hydraulic systems.

What are the emerging trends and technologies in hose inspection and repair?

Advanced non-destructive testing methods, predictive maintenance techniques, and the use of mobile apps for data collection and reporting.