Are you a seasoned Hot Mill Operator seeking a new career path? Discover our professionally built Hot Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

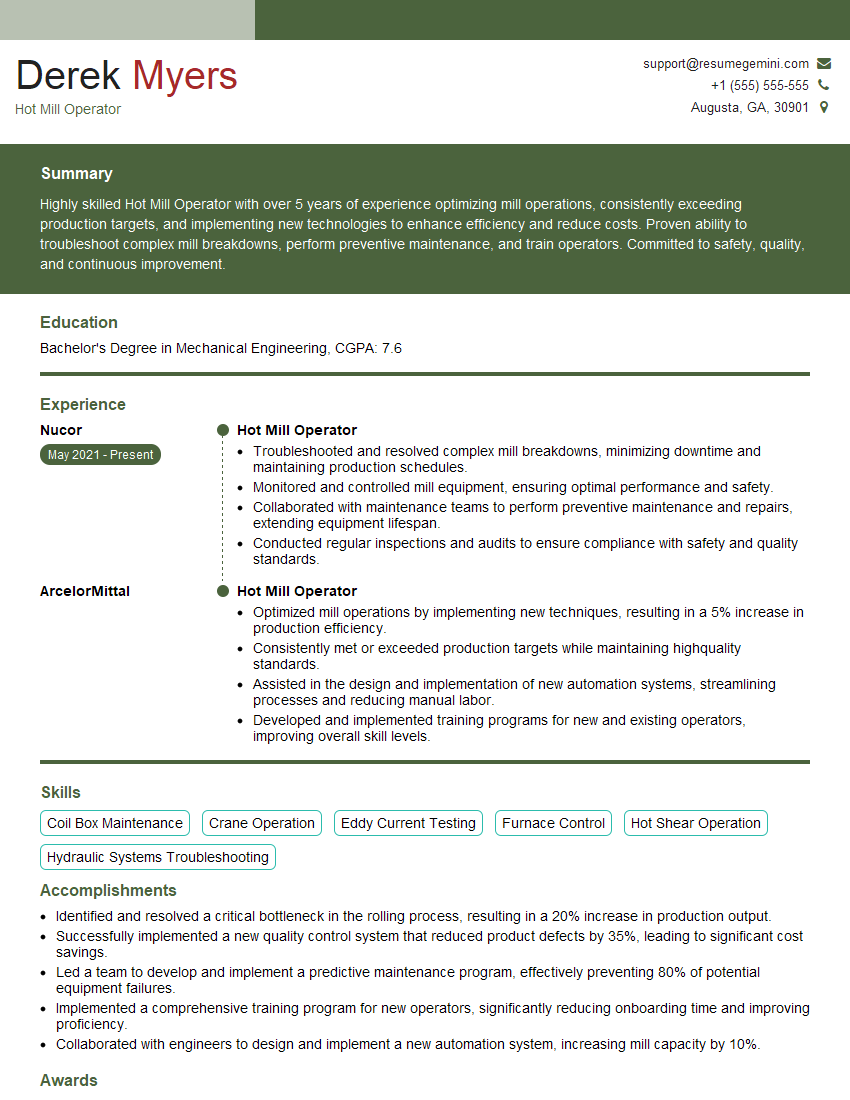

Derek Myers

Hot Mill Operator

Summary

Highly skilled Hot Mill Operator with over 5 years of experience optimizing mill operations, consistently exceeding production targets, and implementing new technologies to enhance efficiency and reduce costs. Proven ability to troubleshoot complex mill breakdowns, perform preventive maintenance, and train operators. Committed to safety, quality, and continuous improvement.

Education

Bachelor’s Degree in Mechanical Engineering

April 2017

Skills

- Coil Box Maintenance

- Crane Operation

- Eddy Current Testing

- Furnace Control

- Hot Shear Operation

- Hydraulic Systems Troubleshooting

Work Experience

Hot Mill Operator

- Troubleshooted and resolved complex mill breakdowns, minimizing downtime and maintaining production schedules.

- Monitored and controlled mill equipment, ensuring optimal performance and safety.

- Collaborated with maintenance teams to perform preventive maintenance and repairs, extending equipment lifespan.

- Conducted regular inspections and audits to ensure compliance with safety and quality standards.

Hot Mill Operator

- Optimized mill operations by implementing new techniques, resulting in a 5% increase in production efficiency.

- Consistently met or exceeded production targets while maintaining highquality standards.

- Assisted in the design and implementation of new automation systems, streamlining processes and reducing manual labor.

- Developed and implemented training programs for new and existing operators, improving overall skill levels.

Accomplishments

- Identified and resolved a critical bottleneck in the rolling process, resulting in a 20% increase in production output.

- Successfully implemented a new quality control system that reduced product defects by 35%, leading to significant cost savings.

- Led a team to develop and implement a predictive maintenance program, effectively preventing 80% of potential equipment failures.

- Implemented a comprehensive training program for new operators, significantly reducing onboarding time and improving proficiency.

- Collaborated with engineers to design and implement a new automation system, increasing mill capacity by 10%.

Awards

- Received the Hot Mill Operator of the Year award for consistently exceeding production targets and maintaining high safety standards.

- Recognized with the Safety Excellence Award for implementing innovative safety initiatives that significantly reduced workplace accidents.

- Awarded the Operational Excellence Award for developing and implementing process improvements that enhanced productivity by 15%.

- Won the Plant Efficiency Award for optimizing the hot mill process, achieving a 10% reduction in energy consumption.

Certificates

- American Welding Society (AWS) Certified Welder

- Association for Iron and Steel Technology (AIST) Basic Steelmaking Certificate

- Crane Operator Certification

- Forklift Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Mill Operator

- Highlight your experience in optimizing mill operations and increasing production efficiency

- Showcase your ability to troubleshoot complex mill breakdowns and resolve them quickly

- Demonstrate your understanding of mill equipment and your commitment to safety

- Quantify your accomplishments whenever possible, using specific metrics and data

Essential Experience Highlights for a Strong Hot Mill Operator Resume

- Optimized mill operations by implementing new techniques, resulting in a 5% increase in production efficiency

- Consistently met or exceeded production targets while maintaining high-quality standards

- Assisted in the design and implementation of new automation systems, streamlining processes and reducing manual labor

- Developed and implemented training programs for new and existing operators, improving overall skill levels

- Troubleshooted and resolved complex mill breakdowns, minimizing downtime and maintaining production schedules

- Monitored and controlled mill equipment, ensuring optimal performance and safety

- Collaborated with maintenance teams to perform preventive maintenance and repairs, extending equipment lifespan

Frequently Asked Questions (FAQ’s) For Hot Mill Operator

What are the primary responsibilities of a Hot Mill Operator?

Hot Mill Operators are responsible for operating and maintaining hot rolling mills, which shape and size steel products. Their duties include monitoring and controlling equipment, troubleshooting breakdowns, performing preventive maintenance, and ensuring the safety and quality of the finished product.

What skills and qualifications are required to become a Hot Mill Operator?

Hot Mill Operators typically need a high school diploma or equivalent, and may also need to complete specialized training programs. They should have strong mechanical aptitude, problem-solving skills, and the ability to work independently and as part of a team. Physical strength and stamina are also important.

What is the work environment of a Hot Mill Operator like?

Hot Mill Operators work in industrial environments, often in close proximity to heavy machinery and molten metal. The work can be physically demanding and may involve exposure to heat, noise, and dust.

What are the career prospects for Hot Mill Operators?

Hot Mill Operators can advance to positions such as Mill Supervisor, Production Manager, or Plant Manager. With additional education and experience, they may also move into roles in engineering, maintenance, or management.

What is the average salary for a Hot Mill Operator?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Hot Mill Operators was $67,850 in May 2021.

What are the safety considerations for Hot Mill Operators?

Hot Mill Operators must adhere to strict safety protocols to minimize the risk of injury. These protocols include wearing appropriate protective gear, following proper operating procedures, and being aware of potential hazards.

What is the role of technology in the work of Hot Mill Operators?

Technology plays an increasingly important role in the work of Hot Mill Operators. Automation and computer-controlled systems are used to improve efficiency, safety, and product quality.

What are the challenges faced by Hot Mill Operators?

Hot Mill Operators face challenges such as working in demanding environments, keeping up with technological advancements, and ensuring the safety and quality of their products.