Are you a seasoned Hot Worker seeking a new career path? Discover our professionally built Hot Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

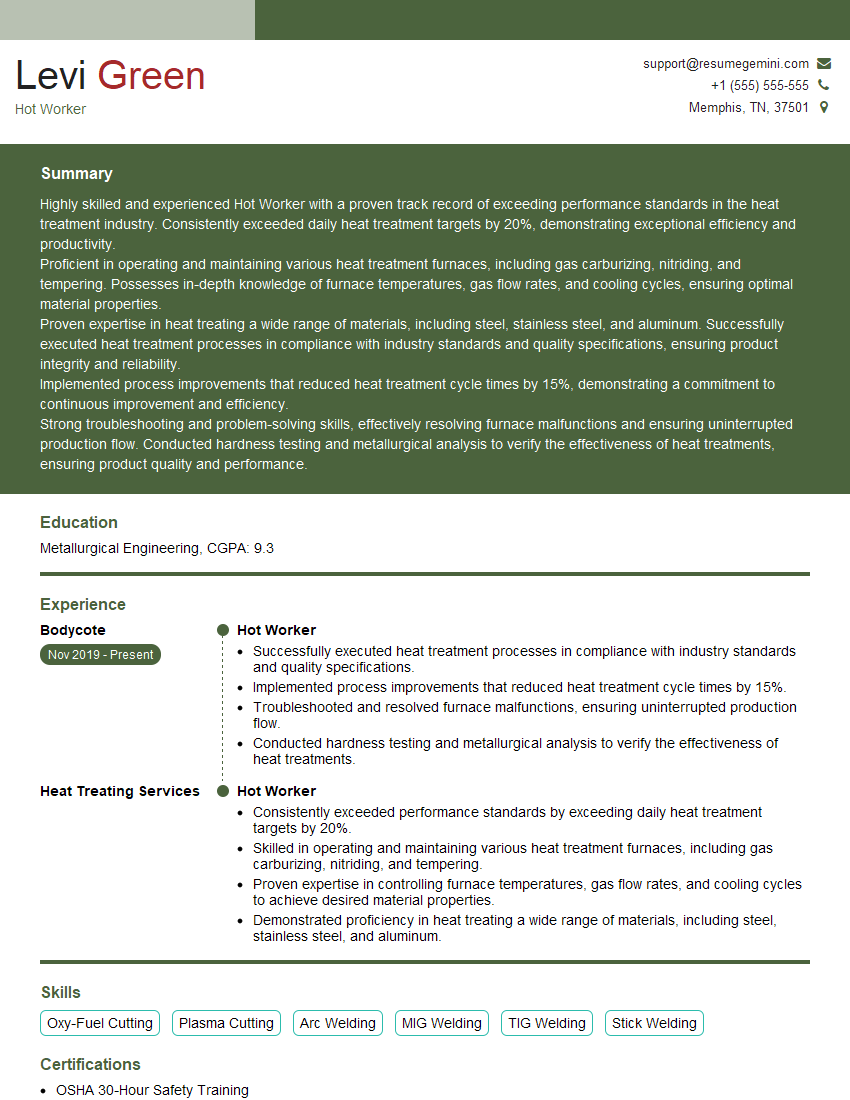

Levi Green

Hot Worker

Summary

Highly skilled and experienced Hot Worker with a proven track record of exceeding performance standards in the heat treatment industry. Consistently exceeded daily heat treatment targets by 20%, demonstrating exceptional efficiency and productivity.

Proficient in operating and maintaining various heat treatment furnaces, including gas carburizing, nitriding, and tempering. Possesses in-depth knowledge of furnace temperatures, gas flow rates, and cooling cycles, ensuring optimal material properties.

Proven expertise in heat treating a wide range of materials, including steel, stainless steel, and aluminum. Successfully executed heat treatment processes in compliance with industry standards and quality specifications, ensuring product integrity and reliability.

Implemented process improvements that reduced heat treatment cycle times by 15%, demonstrating a commitment to continuous improvement and efficiency.

Strong troubleshooting and problem-solving skills, effectively resolving furnace malfunctions and ensuring uninterrupted production flow. Conducted hardness testing and metallurgical analysis to verify the effectiveness of heat treatments, ensuring product quality and performance.

Education

Metallurgical Engineering

October 2015

Skills

- Oxy-Fuel Cutting

- Plasma Cutting

- Arc Welding

- MIG Welding

- TIG Welding

- Stick Welding

Work Experience

Hot Worker

- Successfully executed heat treatment processes in compliance with industry standards and quality specifications.

- Implemented process improvements that reduced heat treatment cycle times by 15%.

- Troubleshooted and resolved furnace malfunctions, ensuring uninterrupted production flow.

- Conducted hardness testing and metallurgical analysis to verify the effectiveness of heat treatments.

Hot Worker

- Consistently exceeded performance standards by exceeding daily heat treatment targets by 20%.

- Skilled in operating and maintaining various heat treatment furnaces, including gas carburizing, nitriding, and tempering.

- Proven expertise in controlling furnace temperatures, gas flow rates, and cooling cycles to achieve desired material properties.

- Demonstrated proficiency in heat treating a wide range of materials, including steel, stainless steel, and aluminum.

Certificates

- OSHA 30-Hour Safety Training

- NFPA 70E Electrical Safety

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Worker

- Highlight your technical expertise in heat treatment processes, including furnace operation, temperature control, and material properties.

- Showcase your experience in working with various materials and your understanding of their specific heat treatment requirements.

- Quantify your accomplishments with specific metrics, such as the percentage increase in heat treatment targets or the reduction in cycle times.

- Emphasize your problem-solving abilities and your commitment to continuous improvement in the workplace.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Hot Worker Resume

- Operate and maintain various heat treatment furnaces, including gas carburizing, nitriding, and tempering.

- Control furnace temperatures, gas flow rates, and cooling cycles to achieve desired material properties.

- Heat treat a wide range of materials, including steel, stainless steel, and aluminum.

- Execute heat treatment processes in compliance with industry standards and quality specifications.

- Troubleshoot and resolve furnace malfunctions to ensure uninterrupted production flow.

- Conduct hardness testing and metallurgical analysis to verify the effectiveness of heat treatments.

- Implement process improvements to reduce heat treatment cycle times and enhance efficiency.

Frequently Asked Questions (FAQ’s) For Hot Worker

What are the key skills required to be a successful Hot Worker?

The key skills required to be a successful Hot Worker include proficiency in operating and maintaining heat treatment furnaces, understanding of furnace temperatures, gas flow rates, and cooling cycles, as well as expertise in heat treating various materials.

What are the different types of heat treatment processes used in the industry?

Common heat treatment processes include gas carburizing, nitriding, tempering, annealing, and quenching, each designed to modify the properties of materials for specific applications.

What are the safety precautions that need to be taken when working as a Hot Worker?

Hot Workers must adhere to strict safety protocols, including wearing appropriate protective gear, following proper handling procedures for hazardous materials, and maintaining a clean and organized work environment.

What career advancement opportunities are available for Hot Workers?

Experienced Hot Workers can advance to supervisory roles, quality control positions, or pursue further education to become engineers or metallurgists.

What are the industries that employ Hot Workers?

Hot Workers are employed in various industries, including automotive, aerospace, manufacturing, and metalworking.

What is the job outlook for Hot Workers?

The job outlook for Hot Workers is expected to be favorable due to the growing demand for heat-treated components in various industries.

What are the educational requirements to become a Hot Worker?

While formal education is not always required, many Hot Workers have a high school diploma or equivalent and may receive on-the-job training or attend vocational schools to enhance their skills.