Are you a seasoned Hydrogenation Still Operator seeking a new career path? Discover our professionally built Hydrogenation Still Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

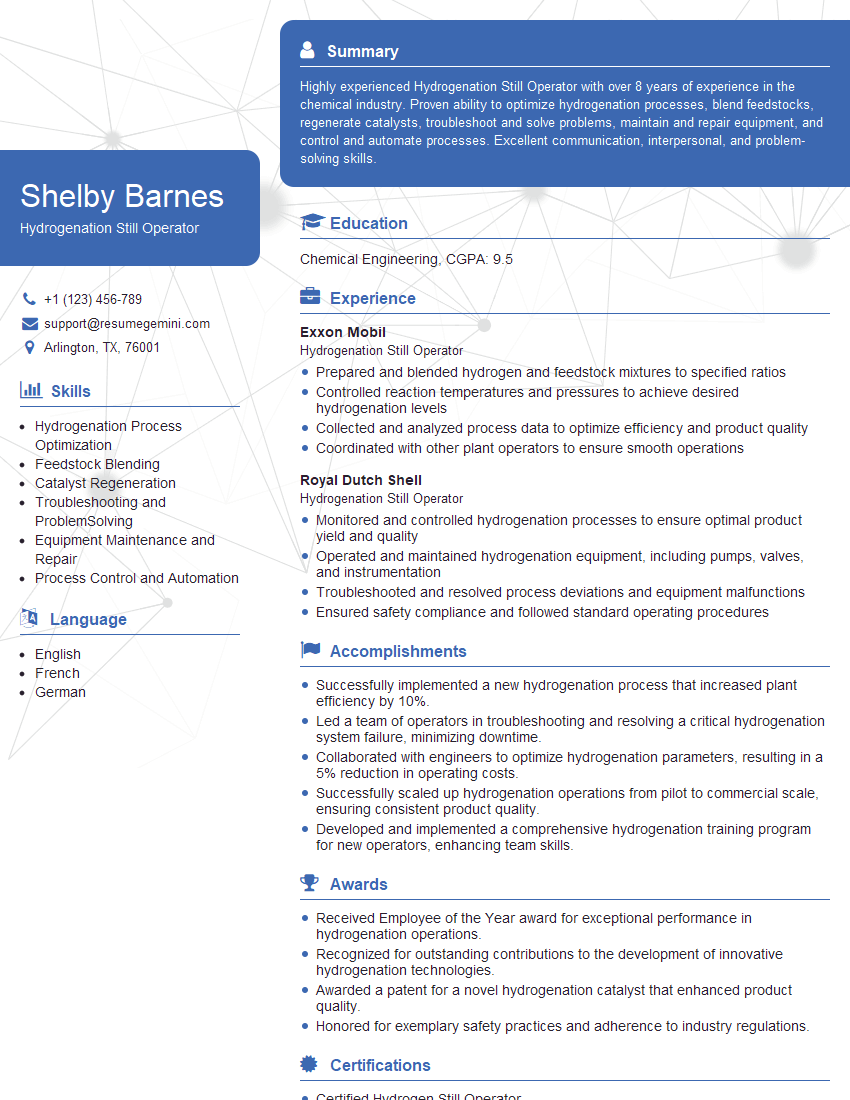

Shelby Barnes

Hydrogenation Still Operator

Summary

Highly experienced Hydrogenation Still Operator with over 8 years of experience in the chemical industry. Proven ability to optimize hydrogenation processes, blend feedstocks, regenerate catalysts, troubleshoot and solve problems, maintain and repair equipment, and control and automate processes. Excellent communication, interpersonal, and problem-solving skills.

Education

Chemical Engineering

July 2018

Skills

- Hydrogenation Process Optimization

- Feedstock Blending

- Catalyst Regeneration

- Troubleshooting and ProblemSolving

- Equipment Maintenance and Repair

- Process Control and Automation

Work Experience

Hydrogenation Still Operator

- Prepared and blended hydrogen and feedstock mixtures to specified ratios

- Controlled reaction temperatures and pressures to achieve desired hydrogenation levels

- Collected and analyzed process data to optimize efficiency and product quality

- Coordinated with other plant operators to ensure smooth operations

Hydrogenation Still Operator

- Monitored and controlled hydrogenation processes to ensure optimal product yield and quality

- Operated and maintained hydrogenation equipment, including pumps, valves, and instrumentation

- Troubleshooted and resolved process deviations and equipment malfunctions

- Ensured safety compliance and followed standard operating procedures

Accomplishments

- Successfully implemented a new hydrogenation process that increased plant efficiency by 10%.

- Led a team of operators in troubleshooting and resolving a critical hydrogenation system failure, minimizing downtime.

- Collaborated with engineers to optimize hydrogenation parameters, resulting in a 5% reduction in operating costs.

- Successfully scaled up hydrogenation operations from pilot to commercial scale, ensuring consistent product quality.

- Developed and implemented a comprehensive hydrogenation training program for new operators, enhancing team skills.

Awards

- Received Employee of the Year award for exceptional performance in hydrogenation operations.

- Recognized for outstanding contributions to the development of innovative hydrogenation technologies.

- Awarded a patent for a novel hydrogenation catalyst that enhanced product quality.

- Honored for exemplary safety practices and adherence to industry regulations.

Certificates

- Certified Hydrogen Still Operator

- OSHA 30Hour HAZWOPER Training

- Confined Space Entry Certification

- Process Control Technology Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydrogenation Still Operator

- Highlight your experience in hydrogenation process optimization.

- Showcase your knowledge of feedstock blending and catalyst regeneration.

- Emphasize your troubleshooting and problem-solving skills.

- Demonstrate your ability to maintain and repair hydrogenation equipment.

- Highlight your understanding of process control and automation.

Essential Experience Highlights for a Strong Hydrogenation Still Operator Resume

- Optimized hydrogenation processes to increase efficiency and reduce costs.

- Blended feedstocks to meet product specifications.

- Regenerated catalysts to extend their lifespan.

- Troubleshooted and solved problems related to hydrogenation equipment and processes.

- Maintained and repaired hydrogenation equipment.

- Controlled and automated hydrogenation processes to ensure quality and safety.

- Developed and implemented process improvements to increase efficiency and productivity.

Frequently Asked Questions (FAQ’s) For Hydrogenation Still Operator

What is the role of a Hydrogenation Still Operator?

A Hydrogenation Still Operator is responsible for operating and maintaining hydrogenation stills, which are used to convert unsaturated fats and oils into saturated fats and oils.

What are the key skills required for a Hydrogenation Still Operator?

Key skills for a Hydrogenation Still Operator include knowledge of hydrogenation processes, feedstock blending, catalyst regeneration, troubleshooting and problem-solving, equipment maintenance and repair, and process control and automation.

What is the work environment of a Hydrogenation Still Operator like?

Hydrogenation Still Operators typically work in industrial settings, such as chemical plants or refineries. They may work indoors or outdoors, and may be exposed to hazardous chemicals and materials.

What is the career outlook for Hydrogenation Still Operators?

The career outlook for Hydrogenation Still Operators is expected to be good, as the demand for hydrogenated fats and oils is increasing in the food and beverage industry.

What are the salary expectations for Hydrogenation Still Operators?

The salary expectations for Hydrogenation Still Operators can vary depending on experience, location, and employer. According to Indeed, the average salary for a Hydrogenation Still Operator in the United States is $72,000 per year.

What are the educational requirements for Hydrogenation Still Operators?

Hydrogenation Still Operators typically have a high school diploma or equivalent and may have some college coursework in chemistry or a related field.