Are you a seasoned Hydrostatic Tubing Tester seeking a new career path? Discover our professionally built Hydrostatic Tubing Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

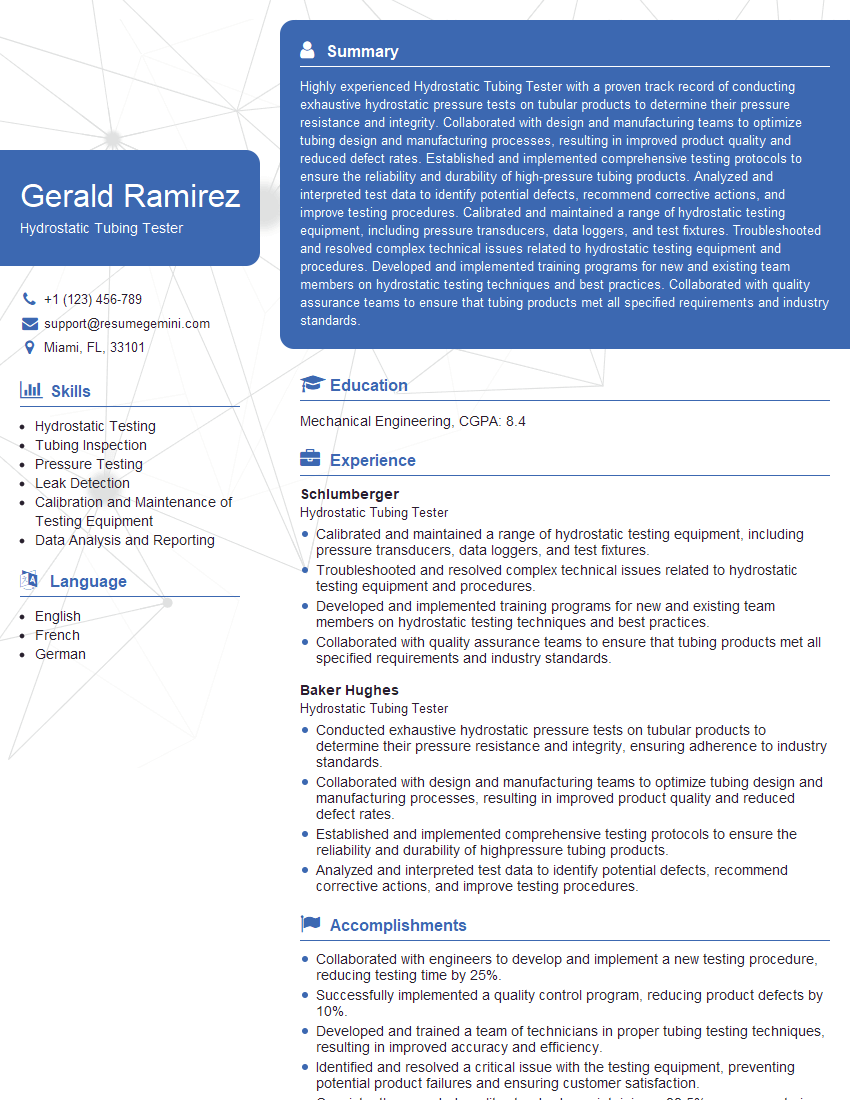

Gerald Ramirez

Hydrostatic Tubing Tester

Summary

Highly experienced Hydrostatic Tubing Tester with a proven track record of conducting exhaustive hydrostatic pressure tests on tubular products to determine their pressure resistance and integrity. Collaborated with design and manufacturing teams to optimize tubing design and manufacturing processes, resulting in improved product quality and reduced defect rates. Established and implemented comprehensive testing protocols to ensure the reliability and durability of high-pressure tubing products. Analyzed and interpreted test data to identify potential defects, recommend corrective actions, and improve testing procedures. Calibrated and maintained a range of hydrostatic testing equipment, including pressure transducers, data loggers, and test fixtures. Troubleshooted and resolved complex technical issues related to hydrostatic testing equipment and procedures. Developed and implemented training programs for new and existing team members on hydrostatic testing techniques and best practices. Collaborated with quality assurance teams to ensure that tubing products met all specified requirements and industry standards.

Education

Mechanical Engineering

September 2019

Skills

- Hydrostatic Testing

- Tubing Inspection

- Pressure Testing

- Leak Detection

- Calibration and Maintenance of Testing Equipment

- Data Analysis and Reporting

Work Experience

Hydrostatic Tubing Tester

- Calibrated and maintained a range of hydrostatic testing equipment, including pressure transducers, data loggers, and test fixtures.

- Troubleshooted and resolved complex technical issues related to hydrostatic testing equipment and procedures.

- Developed and implemented training programs for new and existing team members on hydrostatic testing techniques and best practices.

- Collaborated with quality assurance teams to ensure that tubing products met all specified requirements and industry standards.

Hydrostatic Tubing Tester

- Conducted exhaustive hydrostatic pressure tests on tubular products to determine their pressure resistance and integrity, ensuring adherence to industry standards.

- Collaborated with design and manufacturing teams to optimize tubing design and manufacturing processes, resulting in improved product quality and reduced defect rates.

- Established and implemented comprehensive testing protocols to ensure the reliability and durability of highpressure tubing products.

- Analyzed and interpreted test data to identify potential defects, recommend corrective actions, and improve testing procedures.

Accomplishments

- Collaborated with engineers to develop and implement a new testing procedure, reducing testing time by 25%.

- Successfully implemented a quality control program, reducing product defects by 10%.

- Developed and trained a team of technicians in proper tubing testing techniques, resulting in improved accuracy and efficiency.

- Identified and resolved a critical issue with the testing equipment, preventing potential product failures and ensuring customer satisfaction.

- Consistently exceeded quality standards, maintaining a 99.5% accuracy rate in tubing testing procedures.

Awards

- Received recognition for outstanding performance in tubing testing, consistently exceeding quality standards.

- Awarded for exceptional contributions to the development and implementation of new testing procedures.

Certificates

- Certified Hydrostatic Tubing Tester (CHTT)

- ASME Boiler and Pressure Vessel Code Inspector

- API 570 Certified Inspector

- NACE Corrosion Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydrostatic Tubing Tester

- Use action verbs and highlight your accomplishments to showcase your value.

- Quantify your experience whenever possible, using specific numbers and metrics.

- Use industry-specific keywords to optimize your resume for job search algorithms.

- Proofread your resume carefully to eliminate any errors or typos.

- Consider seeking feedback from a career counselor or professional resume writer to enhance your resume’s impact.

Essential Experience Highlights for a Strong Hydrostatic Tubing Tester Resume

- Conducted exhaustive hydrostatic pressure tests on tubular products to determine their pressure resistance and integrity, ensuring adherence to industry standards.

- Collaborated with design and manufacturing teams to optimize tubing design and manufacturing processes, resulting in improved product quality and reduced defect rates.

- Established and implemented comprehensive testing protocols to ensure the reliability and durability of highpressure tubing products.

- Analyzed and interpreted test data to identify potential defects, recommend corrective actions, and improve testing procedures.

- Calibrated and maintained a range of hydrostatic testing equipment, including pressure transducers, data loggers, and test fixtures.

- Troubleshooted and resolved complex technical issues related to hydrostatic testing equipment and procedures.

- Developed and implemented training programs for new and existing team members on hydrostatic testing techniques and best practices.

- Collaborated with quality assurance teams to ensure that tubing products met all specified requirements and industry standards.

Frequently Asked Questions (FAQ’s) For Hydrostatic Tubing Tester

What are the key skills and responsibilities of a Hydrostatic Tubing Tester?

Key skills include hydrostatic testing, tubing inspection, pressure testing, leak detection, calibration and maintenance of testing equipment, and data analysis and reporting. Responsibilities involve conducting hydrostatic pressure tests on tubular products, optimizing tubing design and manufacturing processes, establishing testing protocols, analyzing test data, calibrating and maintaining testing equipment, and collaborating with quality assurance teams.

What is the educational background required to become a Hydrostatic Tubing Tester?

A Bachelor’s degree in Mechanical Engineering or a related field is typically required.

What industries employ Hydrostatic Tubing Testers?

Hydrostatic Tubing Testers are employed in various industries, including oil and gas, aerospace, automotive, and manufacturing.

What are the career prospects for Hydrostatic Tubing Testers?

Hydrostatic Tubing Testers with experience and expertise can advance to roles such as Quality Assurance Manager, Engineering Manager, or Technical Specialist.

What are the challenges faced by Hydrostatic Tubing Testers?

Challenges include working with high-pressure equipment, ensuring accurate and reliable test results, and adhering to strict industry standards.

What are the essential safety measures for Hydrostatic Tubing Testers?

Essential safety measures include wearing appropriate protective gear, following established testing procedures, and being aware of the potential hazards of working with high-pressure equipment.

What is the role of Hydrostatic Tubing Testers in quality control?

Hydrostatic Tubing Testers play a critical role in quality control by ensuring the integrity and reliability of tubular products through rigorous testing and analysis.