Are you a seasoned Icing Machine Operator seeking a new career path? Discover our professionally built Icing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

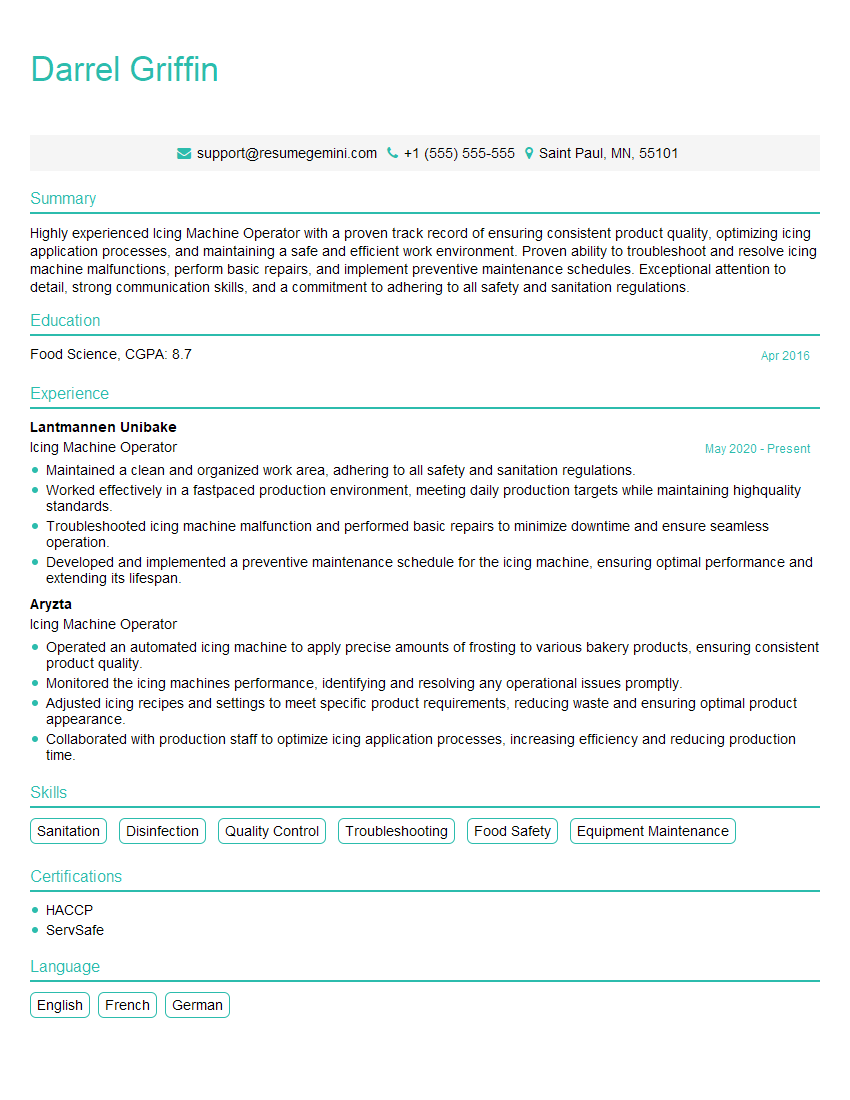

Darrel Griffin

Icing Machine Operator

Summary

Highly experienced Icing Machine Operator with a proven track record of ensuring consistent product quality, optimizing icing application processes, and maintaining a safe and efficient work environment. Proven ability to troubleshoot and resolve icing machine malfunctions, perform basic repairs, and implement preventive maintenance schedules. Exceptional attention to detail, strong communication skills, and a commitment to adhering to all safety and sanitation regulations.

Education

Food Science

April 2016

Skills

- Sanitation

- Disinfection

- Quality Control

- Troubleshooting

- Food Safety

- Equipment Maintenance

Work Experience

Icing Machine Operator

- Maintained a clean and organized work area, adhering to all safety and sanitation regulations.

- Worked effectively in a fastpaced production environment, meeting daily production targets while maintaining highquality standards.

- Troubleshooted icing machine malfunction and performed basic repairs to minimize downtime and ensure seamless operation.

- Developed and implemented a preventive maintenance schedule for the icing machine, ensuring optimal performance and extending its lifespan.

Icing Machine Operator

- Operated an automated icing machine to apply precise amounts of frosting to various bakery products, ensuring consistent product quality.

- Monitored the icing machines performance, identifying and resolving any operational issues promptly.

- Adjusted icing recipes and settings to meet specific product requirements, reducing waste and ensuring optimal product appearance.

- Collaborated with production staff to optimize icing application processes, increasing efficiency and reducing production time.

Certificates

- HACCP

- ServSafe

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Icing Machine Operator

- Highlight your experience operating and maintaining automated icing machines in a fast-paced production environment.

- Quantify your accomplishments whenever possible, such as the percentage of production time saved or the reduction in waste achieved.

- Demonstrate your knowledge of food safety and sanitation regulations, as well as your ability to maintain a clean and organized work area.

- Showcase your problem-solving skills and ability to troubleshoot icing machine malfunctions and perform basic repairs.

- Emphasize your ability to work effectively as part of a production team and collaborate with others to optimize icing application processes.

Essential Experience Highlights for a Strong Icing Machine Operator Resume

- Operate an automated icing machine to apply precise amounts of frosting to various bakery products, ensuring consistent product quality.

- Monitor the icing machine’s performance, identifying and resolving any operational issues promptly.

- Adjust icing recipes and settings to meet specific product requirements, reducing waste and ensuring optimal product appearance.

- Collaborate with production staff to optimize icing application processes, increasing efficiency and reducing production time.

- Maintain a clean and organized work area, adhering to all safety and sanitation regulations.

- Troubleshoot icing machine malfunctions and perform basic repairs to minimize downtime and ensure seamless operation.

- Develop and implement a preventive maintenance schedule for the icing machine, ensuring optimal performance and extending its lifespan.

- Work effectively in a fast-paced production environment, meeting daily production targets while maintaining high-quality standards.

Frequently Asked Questions (FAQ’s) For Icing Machine Operator

What are the primary responsibilities of an Icing Machine Operator?

The primary responsibilities include operating an automated icing machine, monitoring its performance, adjusting icing recipes, maintaining a clean work area, troubleshooting malfunctions, and implementing preventive maintenance schedules.

What skills are essential for success as an Icing Machine Operator?

Essential skills include sanitation, disinfection, quality control, troubleshooting, food safety, and equipment maintenance.

What type of education or training is required for an Icing Machine Operator?

While formal education requirements may vary, a degree in Food Science or a related field is beneficial.

What are the career advancement opportunities for an Icing Machine Operator?

With experience and additional training, Icing Machine Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Maintenance Technician.

What are the earning prospects for an Icing Machine Operator?

Earning prospects can vary depending on experience, location, and company size, but the average salary range is between $25,000 and $45,000.

What are the challenges faced by Icing Machine Operators?

Common challenges include working in a fast-paced production environment, maintaining high-quality standards, and troubleshooting icing machine malfunctions.

What is the work environment like for an Icing Machine Operator?

Icing Machine Operators typically work in a production facility, standing for extended periods and operating machinery.

What are the safety precautions that Icing Machine Operators must follow?

Safety precautions include wearing appropriate safety gear, adhering to lockout/tagout procedures, and following food safety regulations.