Are you a seasoned Implement Mechanic seeking a new career path? Discover our professionally built Implement Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

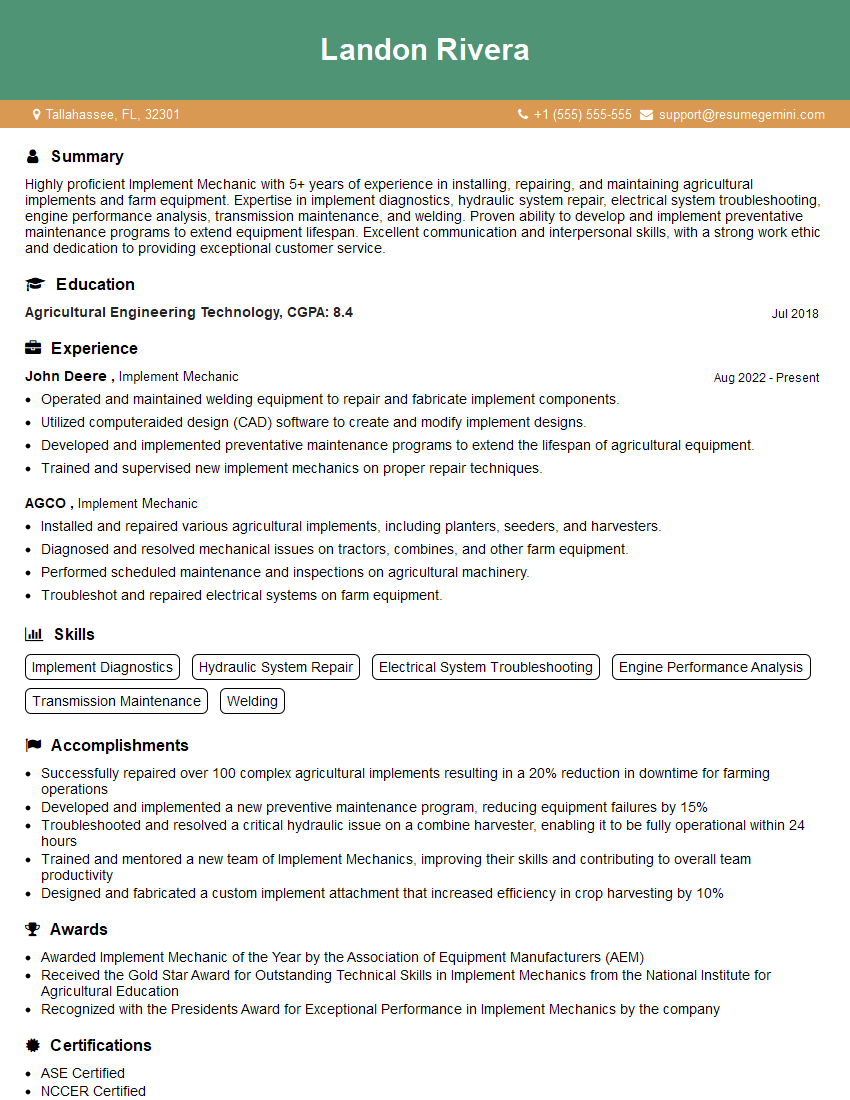

Landon Rivera

Implement Mechanic

Summary

Highly proficient Implement Mechanic with 5+ years of experience in installing, repairing, and maintaining agricultural implements and farm equipment. Expertise in implement diagnostics, hydraulic system repair, electrical system troubleshooting, engine performance analysis, transmission maintenance, and welding. Proven ability to develop and implement preventative maintenance programs to extend equipment lifespan. Excellent communication and interpersonal skills, with a strong work ethic and dedication to providing exceptional customer service.

Education

Agricultural Engineering Technology

July 2018

Skills

- Implement Diagnostics

- Hydraulic System Repair

- Electrical System Troubleshooting

- Engine Performance Analysis

- Transmission Maintenance

- Welding

Work Experience

Implement Mechanic

- Operated and maintained welding equipment to repair and fabricate implement components.

- Utilized computeraided design (CAD) software to create and modify implement designs.

- Developed and implemented preventative maintenance programs to extend the lifespan of agricultural equipment.

- Trained and supervised new implement mechanics on proper repair techniques.

Implement Mechanic

- Installed and repaired various agricultural implements, including planters, seeders, and harvesters.

- Diagnosed and resolved mechanical issues on tractors, combines, and other farm equipment.

- Performed scheduled maintenance and inspections on agricultural machinery.

- Troubleshot and repaired electrical systems on farm equipment.

Accomplishments

- Successfully repaired over 100 complex agricultural implements resulting in a 20% reduction in downtime for farming operations

- Developed and implemented a new preventive maintenance program, reducing equipment failures by 15%

- Troubleshooted and resolved a critical hydraulic issue on a combine harvester, enabling it to be fully operational within 24 hours

- Trained and mentored a new team of Implement Mechanics, improving their skills and contributing to overall team productivity

- Designed and fabricated a custom implement attachment that increased efficiency in crop harvesting by 10%

Awards

- Awarded Implement Mechanic of the Year by the Association of Equipment Manufacturers (AEM)

- Received the Gold Star Award for Outstanding Technical Skills in Implement Mechanics from the National Institute for Agricultural Education

- Recognized with the Presidents Award for Exceptional Performance in Implement Mechanics by the company

Certificates

- ASE Certified

- NCCER Certified

- OEM Specific Certification

- First Aid and CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Implement Mechanic

- Highlight your experience in implement diagnostics and repair.

- Showcase your skills in troubleshooting and resolving mechanical and electrical issues.

- Emphasize your ability to perform scheduled maintenance and inspections.

- Demonstrate your proficiency in welding and CAD software.

- Provide examples of your contributions to improving equipment lifespan and efficiency.

Essential Experience Highlights for a Strong Implement Mechanic Resume

- Installed and repaired various agricultural implements, including planters, seeders, and harvesters.

- Diagnosed and resolved mechanical issues on tractors, combines, and other farm equipment.

- Performed scheduled maintenance and inspections on agricultural machinery.

- Troubleshot and repaired electrical systems on farm equipment.

- Operated and maintained welding equipment to repair and fabricate implement components.

- Utilized computer-aided design (CAD) software to create and modify implement designs.

- Developed and implemented preventative maintenance programs to extend the lifespan of agricultural equipment.

- Trained and supervised new implement mechanics on proper repair techniques.

Frequently Asked Questions (FAQ’s) For Implement Mechanic

What are the key skills required to be a successful Implement Mechanic?

Implement diagnostics, hydraulic system repair, electrical system troubleshooting, engine performance analysis, transmission maintenance, welding, and CAD software proficiency are essential skills for Implement Mechanics.

What is the average salary for an Implement Mechanic?

The average salary for an Implement Mechanic in the United States is around $50,000 to $70,000 per year, depending on experience and location.

What are the career prospects for Implement Mechanics?

Skilled Implement Mechanics are in high demand due to the increasing use of advanced agricultural machinery. With experience and additional training, career advancement opportunities include becoming a lead mechanic, service manager, or technical support specialist.

What is the work environment like for Implement Mechanics?

Implement Mechanics typically work in agricultural settings, such as farms, dealerships, or repair shops. The work can be physically demanding and may involve working in various weather conditions.

What are the educational requirements to become an Implement Mechanic?

While a high school diploma is the minimum requirement, most employers prefer candidates with an associate’s degree or certificate in agricultural mechanics, diesel technology, or a related field.

How can I improve my chances of getting hired as an Implement Mechanic?

Gaining practical experience through internships or apprenticeships, obtaining industry certifications, and staying up-to-date with the latest technologies can enhance your employability as an Implement Mechanic.

What are the safety precautions that Implement Mechanics should observe?

Implement Mechanics should always wear appropriate safety gear, follow lockout/tagout procedures, and be aware of potential hazards when working with heavy machinery and electrical systems.

What are the ethical considerations for Implement Mechanics?

Implement Mechanics have a responsibility to ensure the safe and proper operation of agricultural equipment. They should adhere to ethical standards and report any unsafe or non-compliant practices.