Are you a seasoned Impregnation Operator seeking a new career path? Discover our professionally built Impregnation Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

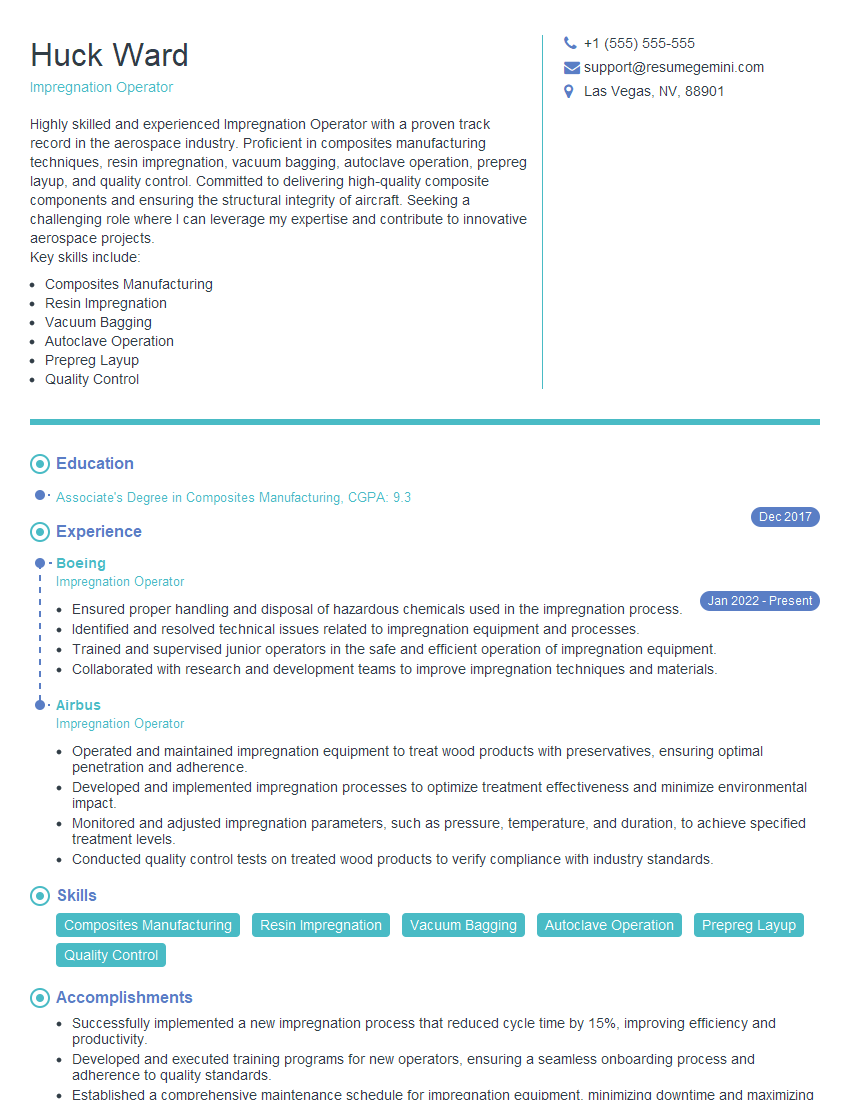

Huck Ward

Impregnation Operator

Summary

Highly skilled and experienced Impregnation Operator with a proven track record in the aerospace industry. Proficient in composites manufacturing techniques, resin impregnation, vacuum bagging, autoclave operation, prepreg layup, and quality control. Committed to delivering high-quality composite components and ensuring the structural integrity of aircraft. Seeking a challenging role where I can leverage my expertise and contribute to innovative aerospace projects.

Key skills include:

- Composites Manufacturing

- Resin Impregnation

- Vacuum Bagging

- Autoclave Operation

- Prepreg Layup

- Quality Control

Education

Associate’s Degree in Composites Manufacturing

December 2017

Skills

- Composites Manufacturing

- Resin Impregnation

- Vacuum Bagging

- Autoclave Operation

- Prepreg Layup

- Quality Control

Work Experience

Impregnation Operator

- Ensured proper handling and disposal of hazardous chemicals used in the impregnation process.

- Identified and resolved technical issues related to impregnation equipment and processes.

- Trained and supervised junior operators in the safe and efficient operation of impregnation equipment.

- Collaborated with research and development teams to improve impregnation techniques and materials.

Impregnation Operator

- Operated and maintained impregnation equipment to treat wood products with preservatives, ensuring optimal penetration and adherence.

- Developed and implemented impregnation processes to optimize treatment effectiveness and minimize environmental impact.

- Monitored and adjusted impregnation parameters, such as pressure, temperature, and duration, to achieve specified treatment levels.

- Conducted quality control tests on treated wood products to verify compliance with industry standards.

Accomplishments

- Successfully implemented a new impregnation process that reduced cycle time by 15%, improving efficiency and productivity.

- Developed and executed training programs for new operators, ensuring a seamless onboarding process and adherence to quality standards.

- Established a comprehensive maintenance schedule for impregnation equipment, minimizing downtime and maximizing equipment lifespan.

- Identified and resolved manufacturing defects in impregnated components, contributing to improved product quality and customer satisfaction.

- Collaborated with engineering team to optimize impregnation parameters, enhancing product performance and reducing material waste.

Certificates

- Composite Manufacturing Technician (CMT)

- Vacuum Bagging Certification

- Autoclave Operator Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Impregnation Operator

- Highlight your technical skills. Impregnation Operators need to be proficient in composites manufacturing techniques, resin impregnation, vacuum bagging, autoclave operation, prepreg layup, and quality control. Make sure to list these skills prominently on your resume.

- Quantify your experience. Whenever possible, use numbers to quantify your experience. For example, instead of saying “Operated impregnation machines,” you could say “Operated impregnation machines to produce over 100,000 composite parts per year.”

- Use keywords. When writing your resume, use keywords that potential employers will be searching for. Some common keywords for Impregnation Operators include “composites manufacturing,” “resin impregnation,” “vacuum bagging,” “autoclave operation,” “prepreg layup,” and “quality control.”

- Proofread your resume carefully. Before you submit your resume, make sure to proofread it carefully for any errors. Typos and grammatical errors can make a bad impression on potential employers.

Essential Experience Highlights for a Strong Impregnation Operator Resume

- Operate impregnation machines to apply resin to prepreg materials.

- Prepare prepreg materials for impregnation by cutting, cleaning, and stacking.

- Monitor impregnation process and adjust parameters to ensure optimal resin absorption.

- Perform vacuum bagging to remove air and excess resin from composite parts.

- Operate autoclaves to cure composite parts under controlled temperature and pressure.

- Conduct quality control inspections to ensure the integrity and conformance of composite components.

- Maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Impregnation Operator

What is the role of an Impregnation Operator?

Impregnation Operators are responsible for applying resin to prepreg materials used in the production of composite parts. They use impregnation machines to apply resin to the prepreg materials, which are then vacuum bagged and cured in an autoclave.

What are the qualifications for an Impregnation Operator?

Impregnation Operators typically have an associate’s degree in composites manufacturing or a related field. They also have experience in operating impregnation machines, vacuum bagging, and autoclaves.

What are the key skills for an Impregnation Operator?

Key skills for an Impregnation Operator include proficiency in composites manufacturing techniques, resin impregnation, vacuum bagging, autoclave operation, prepreg layup, and quality control.

What is the work environment for an Impregnation Operator?

Impregnation Operators typically work in a manufacturing environment. They may be exposed to hazardous chemicals and fumes, so they must wear appropriate safety gear.

What is the career outlook for an Impregnation Operator?

The career outlook for Impregnation Operators is expected to be good. The demand for composite materials is growing, so there will be a need for skilled Impregnation Operators to produce these materials.

What are the salary expectations for an Impregnation Operator?

Salary expectations for Impregnation Operators vary depending on their experience, skills, and location. However, the median salary for Impregnation Operators is around $25,000 per year.

What are the benefits of working as an Impregnation Operator?

Benefits of working as an Impregnation Operator include a good salary, job security, and the opportunity to work with cutting-edge technology.