Are you a seasoned Impregnator Operator seeking a new career path? Discover our professionally built Impregnator Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

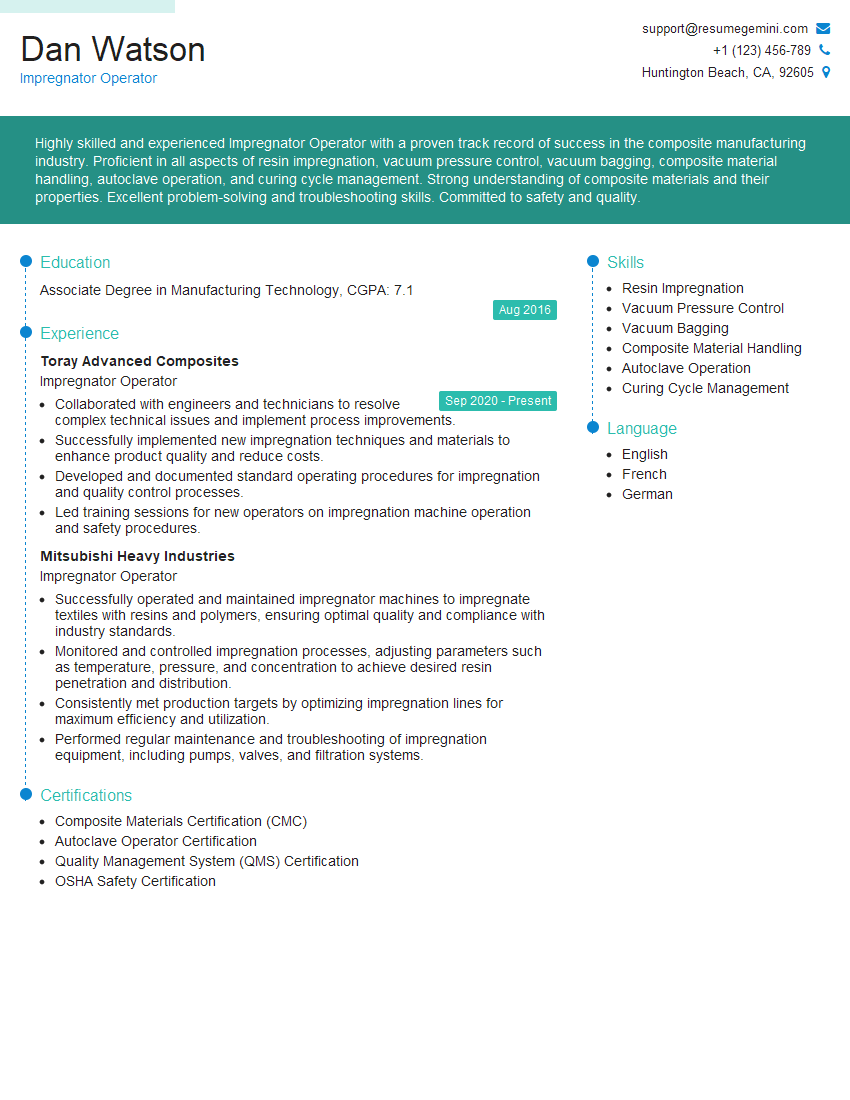

Dan Watson

Impregnator Operator

Summary

Highly skilled and experienced Impregnator Operator with a proven track record of success in the composite manufacturing industry. Proficient in all aspects of resin impregnation, vacuum pressure control, vacuum bagging, composite material handling, autoclave operation, and curing cycle management. Strong understanding of composite materials and their properties. Excellent problem-solving and troubleshooting skills. Committed to safety and quality.

Education

Associate Degree in Manufacturing Technology

August 2016

Skills

- Resin Impregnation

- Vacuum Pressure Control

- Vacuum Bagging

- Composite Material Handling

- Autoclave Operation

- Curing Cycle Management

Work Experience

Impregnator Operator

- Collaborated with engineers and technicians to resolve complex technical issues and implement process improvements.

- Successfully implemented new impregnation techniques and materials to enhance product quality and reduce costs.

- Developed and documented standard operating procedures for impregnation and quality control processes.

- Led training sessions for new operators on impregnation machine operation and safety procedures.

Impregnator Operator

- Successfully operated and maintained impregnator machines to impregnate textiles with resins and polymers, ensuring optimal quality and compliance with industry standards.

- Monitored and controlled impregnation processes, adjusting parameters such as temperature, pressure, and concentration to achieve desired resin penetration and distribution.

- Consistently met production targets by optimizing impregnation lines for maximum efficiency and utilization.

- Performed regular maintenance and troubleshooting of impregnation equipment, including pumps, valves, and filtration systems.

Certificates

- Composite Materials Certification (CMC)

- Autoclave Operator Certification

- Quality Management System (QMS) Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Impregnator Operator

- Highlight your experience and skills in resin impregnation, vacuum pressure control, and autoclave operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, and ask a friend or family member to review it as well.

- Consider including a cover letter that highlights your interest in the position and how your skills and experience match the company’s needs.

Essential Experience Highlights for a Strong Impregnator Operator Resume

- Operate and maintain impregnator machines to impregnate composite materials with resin

- Control vacuum pressure to ensure proper resin impregnation and consolidation

- Prepare and apply vacuum bags to composite assemblies to create a sealed environment for resin infusion

- Handle and store composite materials properly to prevent damage and contamination

- Operate autoclaves to cure composite assemblies under controlled temperature and pressure

- Monitor and control curing cycles to ensure proper composite properties

- Troubleshoot and resolve issues related to resin impregnation, vacuum pressure control, and curing

Frequently Asked Questions (FAQ’s) For Impregnator Operator

What is the role of an Impregnator Operator?

An Impregnator Operator is responsible for impregnating composite materials with resin using an impregnator machine. They also control vacuum pressure, prepare and apply vacuum bags, handle and store composite materials, operate autoclaves, and monitor and control curing cycles.

What skills are required to be an Impregnator Operator?

Impregnator Operators typically need to have a strong understanding of composite materials and their properties, as well as experience in resin impregnation, vacuum pressure control, vacuum bagging, composite material handling, autoclave operation, and curing cycle management.

What is the work environment of an Impregnator Operator?

Impregnator Operators typically work in a manufacturing environment, often in close proximity to machines and equipment. They may also be required to work in confined spaces or in areas with hazardous materials.

What are the career prospects for an Impregnator Operator?

Impregnator Operators can advance to positions such as Composite Production Supervisor, Quality Control Inspector, or Production Manager. They may also choose to specialize in a particular area of composite manufacturing, such as aerospace or automotive.

What is the salary range for an Impregnator Operator?

The salary range for an Impregnator Operator can vary depending on experience, location, and employer. According to Salary.com, the average salary for an Impregnator Operator in the United States is $24.50 per hour.

What are the benefits of working as an Impregnator Operator?

Some of the benefits of working as an Impregnator Operator include job security, competitive pay, and the opportunity to work with cutting-edge technology.