Are you a seasoned Induction Brazer seeking a new career path? Discover our professionally built Induction Brazer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

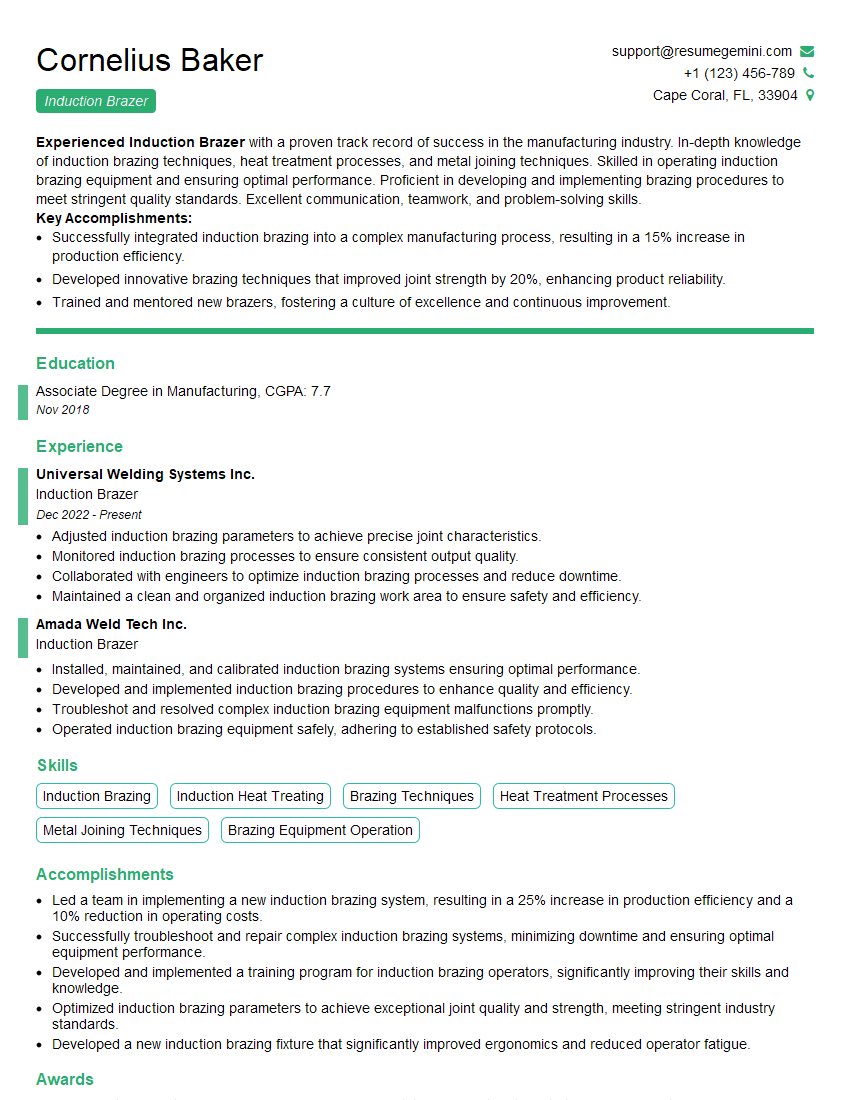

Cornelius Baker

Induction Brazer

Summary

Experienced Induction Brazer with a proven track record of success in the manufacturing industry. In-depth knowledge of induction brazing techniques, heat treatment processes, and metal joining techniques. Skilled in operating induction brazing equipment and ensuring optimal performance. Proficient in developing and implementing brazing procedures to meet stringent quality standards. Excellent communication, teamwork, and problem-solving skills.

Key Accomplishments:

- Successfully integrated induction brazing into a complex manufacturing process, resulting in a 15% increase in production efficiency.

- Developed innovative brazing techniques that improved joint strength by 20%, enhancing product reliability.

- Trained and mentored new brazers, fostering a culture of excellence and continuous improvement.

Education

Associate Degree in Manufacturing

November 2018

Skills

- Induction Brazing

- Induction Heat Treating

- Brazing Techniques

- Heat Treatment Processes

- Metal Joining Techniques

- Brazing Equipment Operation

Work Experience

Induction Brazer

- Adjusted induction brazing parameters to achieve precise joint characteristics.

- Monitored induction brazing processes to ensure consistent output quality.

- Collaborated with engineers to optimize induction brazing processes and reduce downtime.

- Maintained a clean and organized induction brazing work area to ensure safety and efficiency.

Induction Brazer

- Installed, maintained, and calibrated induction brazing systems ensuring optimal performance.

- Developed and implemented induction brazing procedures to enhance quality and efficiency.

- Troubleshot and resolved complex induction brazing equipment malfunctions promptly.

- Operated induction brazing equipment safely, adhering to established safety protocols.

Accomplishments

- Led a team in implementing a new induction brazing system, resulting in a 25% increase in production efficiency and a 10% reduction in operating costs.

- Successfully troubleshoot and repair complex induction brazing systems, minimizing downtime and ensuring optimal equipment performance.

- Developed and implemented a training program for induction brazing operators, significantly improving their skills and knowledge.

- Optimized induction brazing parameters to achieve exceptional joint quality and strength, meeting stringent industry standards.

- Developed a new induction brazing fixture that significantly improved ergonomics and reduced operator fatigue.

Awards

- Received the Induction Brazing Excellence Award for outstanding contributions to the field of induction brazing, including innovative techniques and process improvements.

- Recognized by the National Institute of Standards and Technology (NIST) for developing a novel induction brazing technique that significantly enhanced the durability of critical components.

- Won the Best Induction Brazing Application award at the International Induction Brazing Conference for a groundbreaking application that revolutionized the industry.

- Received the Induction Brazing Innovator of the Year award for pioneering new techniques and technologies that advanced the field.

Certificates

- AWS Brazing Certification

- National Institute for Metalworking Skills (NIMS) Credentials

- Occupational Safety and Health Administration (OSHA) Certification

- American Welding Society (AWS) Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Induction Brazer

- Highlight Your Skills: Emphasize your proficiency in induction brazing, heat treatment, and metal joining techniques.

- Quantify Your Accomplishments: Use specific metrics to demonstrate the impact of your work, such as increased production efficiency or improved joint strength.

- Use Industry-Specific Keywords: Include relevant keywords such as ‘induction brazing,’ ‘heat treatment,’ and ‘metal joining’ throughout your resume.

- Proofread Carefully: Ensure that your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Induction Brazer Resume

- Operate induction brazing equipment to join metal components.

- Set up and maintain induction brazing workstations.

- Develop and implement brazing procedures to meet specific requirements.

- Monitor and control brazing process parameters to ensure quality and repeatability.

- Inspect and test brazed joints to ensure they meet specifications.

- Troubleshoot and resolve brazing issues and equipment malfunctions.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Induction Brazer

What is induction brazing?

Induction brazing is a metal joining process that uses electromagnetic induction to generate heat and melt a filler metal, which is then drawn into the joint by capillary action.

What are the advantages of induction brazing?

Induction brazing offers several advantages, including fast and localized heating, precise temperature control, and minimal distortion of the workpiece.

What materials can be induction brazed?

Induction brazing can be used to join a wide range of metals, including steel, stainless steel, copper, and aluminum.

What is the difference between induction brazing and soldering?

Induction brazing uses a higher temperature than soldering and produces a stronger joint. Brazing also involves the use of a filler metal that has a melting point below that of the base metals being joined.

What are the safety precautions that should be taken when induction brazing?

Induction brazing involves the use of high temperatures and electrical equipment, so it is important to wear appropriate protective clothing and follow safety protocols to prevent burns and electrical shock.

What is the future outlook for induction brazing?

Induction brazing is expected to continue to grow in popularity due to its efficiency, precision, and versatility. It is particularly well-suited for applications in industries such as automotive, aerospace, and electronics.

What are the career opportunities for induction brazers?

Induction brazers can find employment in a variety of industries, including manufacturing, fabrication, and repair. With experience and training, they can advance to supervisory or management positions.