Are you a seasoned Induction Heat Treater seeking a new career path? Discover our professionally built Induction Heat Treater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

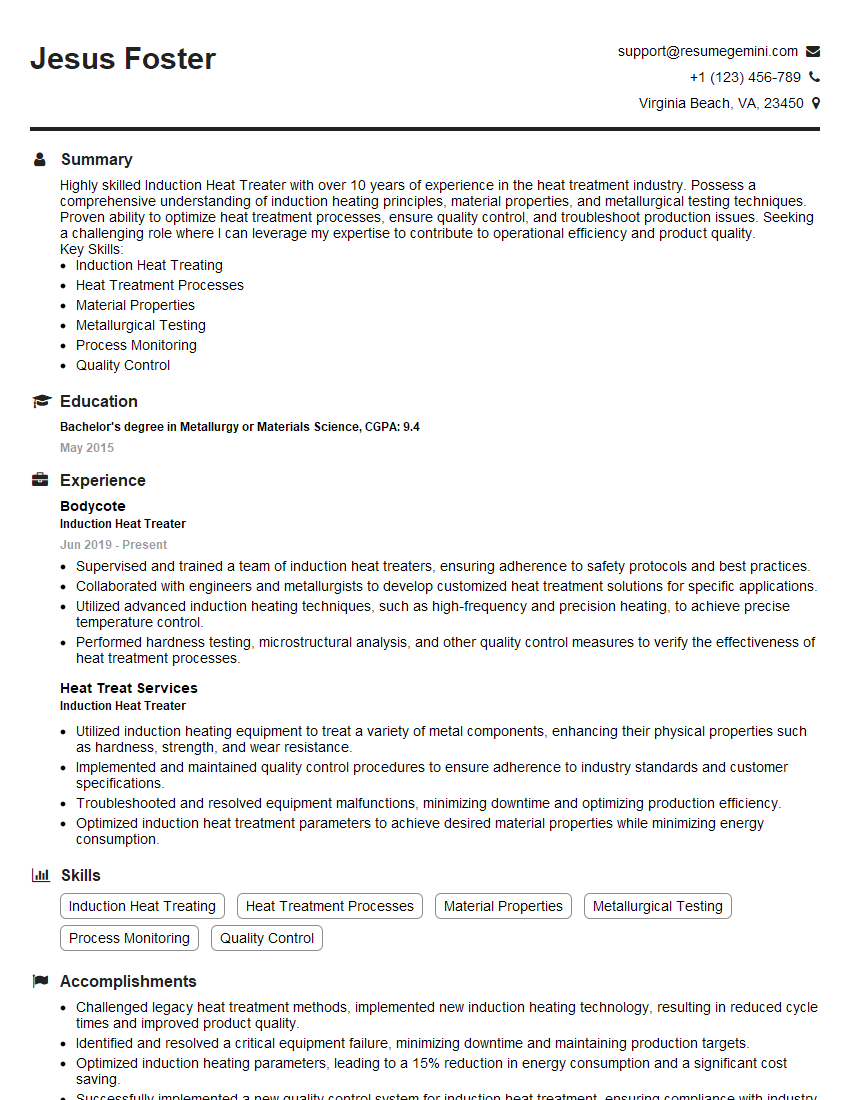

Jesus Foster

Induction Heat Treater

Summary

Highly skilled Induction Heat Treater with over 10 years of experience in the heat treatment industry. Possess a comprehensive understanding of induction heating principles, material properties, and metallurgical testing techniques. Proven ability to optimize heat treatment processes, ensure quality control, and troubleshoot production issues. Seeking a challenging role where I can leverage my expertise to contribute to operational efficiency and product quality.

Key Skills:

- Induction Heat Treating

- Heat Treatment Processes

- Material Properties

- Metallurgical Testing

- Process Monitoring

- Quality Control

Education

Bachelor’s degree in Metallurgy or Materials Science

May 2015

Skills

- Induction Heat Treating

- Heat Treatment Processes

- Material Properties

- Metallurgical Testing

- Process Monitoring

- Quality Control

Work Experience

Induction Heat Treater

- Supervised and trained a team of induction heat treaters, ensuring adherence to safety protocols and best practices.

- Collaborated with engineers and metallurgists to develop customized heat treatment solutions for specific applications.

- Utilized advanced induction heating techniques, such as high-frequency and precision heating, to achieve precise temperature control.

- Performed hardness testing, microstructural analysis, and other quality control measures to verify the effectiveness of heat treatment processes.

Induction Heat Treater

- Utilized induction heating equipment to treat a variety of metal components, enhancing their physical properties such as hardness, strength, and wear resistance.

- Implemented and maintained quality control procedures to ensure adherence to industry standards and customer specifications.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and optimizing production efficiency.

- Optimized induction heat treatment parameters to achieve desired material properties while minimizing energy consumption.

Accomplishments

- Challenged legacy heat treatment methods, implemented new induction heating technology, resulting in reduced cycle times and improved product quality.

- Identified and resolved a critical equipment failure, minimizing downtime and maintaining production targets.

- Optimized induction heating parameters, leading to a 15% reduction in energy consumption and a significant cost saving.

- Successfully implemented a new quality control system for induction heat treatment, ensuring compliance with industry standards.

- Trained and mentored junior heat treaters, fostering their professional development and ensuring knowledge transfer.

Awards

- Recognized for outstanding performance in induction heat treatment, leading to a 20% increase in production efficiency.

- Received an industry award for developing innovative induction heating techniques that improved product quality.

- Honored for contributions to the field of induction heat treatment with a prestigious industry certification.

- Awarded for exceptional safety performance in the induction heat treatment department.

Certificates

- ASME Certified Heat Treater

- NADCAP Certified Heat Treater

- AWS Certified Welding Inspector

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Induction Heat Treater

- Highlight your technical expertise in induction heat treating, material science, and metallurgical testing.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your problem-solving abilities and experience in troubleshooting heat treatment issues.

- Demonstrate your commitment to quality control and continuous improvement.

Essential Experience Highlights for a Strong Induction Heat Treater Resume

- Operate and maintain induction heat treatment equipment to achieve desired material properties.

- Develop and optimize heat treatment processes to enhance product quality and meet customer specifications.

- Perform metallurgical testing and analysis to ensure compliance with industry standards and customer requirements.

- Monitor and control process parameters to ensure consistent and repeatable heat treatment results.

- Collaborate with engineers and production teams to troubleshoot and resolve heat treatment issues.

- Maintain accurate records and documentation of heat treatment processes and results.

- Stay abreast of industry best practices and advancements in heat treatment technologies.

Frequently Asked Questions (FAQ’s) For Induction Heat Treater

What is induction heat treating?

Induction heat treating is a process that uses electromagnetic induction to generate heat within a conductive material. This process is often used to harden or temper metals, improve their wear resistance, and enhance their overall mechanical properties.

What are the benefits of induction heat treating?

Induction heat treating offers several benefits, including precise and localized heating, rapid heating rates, reduced distortion, improved surface hardness, and increased wear resistance.

What materials are suitable for induction heat treating?

Induction heat treating is commonly used for ferrous materials, such as steel and iron, as well as non-ferrous materials like copper, aluminum, and titanium.

What are the key factors to consider when selecting induction heat treating equipment?

When selecting induction heat treating equipment, it is important to consider factors such as the size and shape of the workpiece, the required heat pattern, the desired temperature range, and the production capacity.

What are the safety precautions that should be taken when working with induction heat treating equipment?

Safety precautions for induction heat treating equipment include wearing appropriate personal protective equipment, ensuring proper grounding and electrical connections, and maintaining a safe work environment to prevent burns and other hazards.

What are the career opportunities for induction heat treaters?

Induction heat treaters can find employment opportunities in various industries, including automotive, aerospace, manufacturing, and energy. They can work in research and development, production, quality control, and technical support roles.

What are the professional development opportunities for induction heat treaters?

Induction heat treaters can enhance their skills and knowledge by attending industry conferences, workshops, and training programs. They can also pursue certifications and specialized training in induction heat treating and related fields.